Hydro-pneumatic spring, wheel steering mechanism, wheel and electromobile

A technology of oil-gas spring and steering mechanism, which is applied to steering mechanism, power steering mechanism, electric steering mechanism, etc., can solve problems affecting handling stability, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

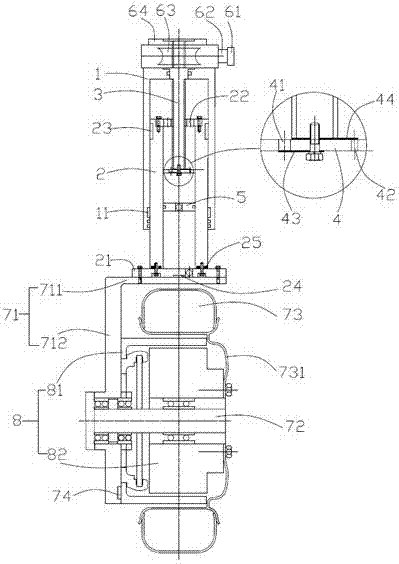

[0036] like figure 1 , this embodiment provides an oil and gas spring, including an oil cylinder, a guide shaft 3, a damping plate 4 and a floating piston 5;

[0037] The oil cylinder includes a cylinder tube 1 and a hollow piston rod 2. The top end of the piston rod 2 is slidably arranged in the cylinder tube 1 and the bottom end is located outside the cylinder tube 1. The inner cavity of the piston rod 2 is connected to the cylinder tube 1. The oil cavity of the cylinder barrel 1 is conducted through the oil passage hole opened at the top of the piston rod 2;

[0038] The guide shaft 3 is coaxially fixed on the top of the cylinder 1 and the bottom end extends into the inner cavity of the piston rod 2; the damping plate 4 is embedded and slidably installed in the inner cavity of the piston rod 2 and It is fixedly connected with the bottom end of the guide shaft 3, and a damping oil passage is arranged on the damping plate 4;

[0039] The floating piston 5 is slidably arrang...

Embodiment 2

[0049] like figure 1 , an embodiment of the present invention provides a steering mechanism for a wheel, including the oil and gas spring provided in the above-mentioned first embodiment, wherein the guide shaft 3 is a spline shaft 3 and is splined with the top end of the piston rod 2, that is, in the The top end of the piston rod 2 is provided with a piston rod spline sleeve 22 , the spline shaft 3 is penetrated on the cylinder barrel 1 and the top end is connected with a driving unit for driving it to rotate around its own axis.

[0050] Continuing the steering mechanism of the above-mentioned wheels, such as figure 1 , the drive unit includes a drive motor 61, a steering worm gear 63 and a steering worm 62, the steering worm gear 63 is coaxially sleeved with the spline shaft 3, and the steering worm 62 meshes with the steering worm gear 63 and is The drive motor 61 is connected. Since the driving motor 61 controls the steering of the wheel through the steering worm 62 and...

Embodiment 3

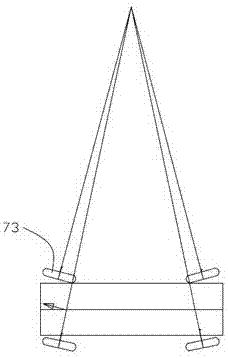

[0054] like figure 1 , the present invention also provides a wheel, including a wheel body 73, a wheel axle 72 and a wheel axle seat 71, the wheel axle 72 is mounted on the wheel axle seat 71 and connected with the wheel body 73, and also includes the above embodiments 2. The steering mechanism of the wheels provided.

[0055] The axle seat 71 includes a vertical section 712 for connecting with the wheel axle 72 and a horizontal section 711 connected to the top of the vertical section 712 and extending toward the outside of the vehicle body. The bottom end of the piston rod 2 is connected to the The top of the horizontal section 711 is fixedly connected. Preferably, the vertical section 712 and the horizontal section 711 are both disc-shaped structures; in the above-mentioned embodiment provided with the piston rod lower seat 21, the piston rod lower seat 21 is fixedly connected to the horizontal section 711, such as by Bolts, etc. Further preferably, a vertical load sensor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com