Oil-gas spring, wheel steering mechanism, wheel and vehicle

A technology of oil-pneumatic springs and wheels, which is applied in the field of vehicles and wheels, can solve problems such as difficult realization, and achieve the effects of improving mobility, high passability, and good controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

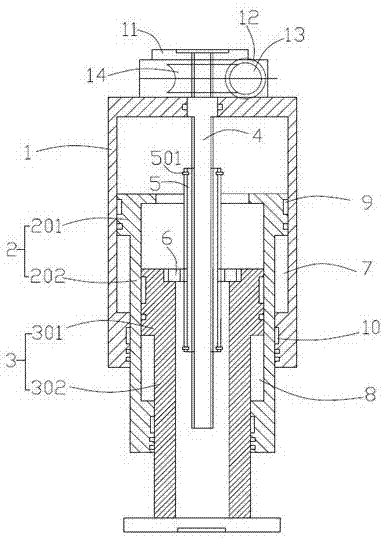

[0041] Such as figure 1 with figure 2 , The embodiment of the present invention provides an oil-gas spring, including an oil cylinder, an elastic damping unit, and an oil circuit unit. The oil cylinder includes a piston rod 3 and a multi-stage cylinder tube nested step by step from the outside to the inside; each adjacent two-stage cylinder In the tube, the outer wall of the inner cylinder tube 2 has a stepped shaft structure with a wide upper and a narrow bottom. The large-diameter section 201 of the inner cylinder 2 is embedded and slidably arranged in the outer cylinder 1, and the top end is provided with the outer cylinder tube. 1 The inner cavity is connected to the oil hole, the small diameter section 202 of the inner cylinder tube 2 penetrates the bottom end of the outer cylinder tube 1 and surrounds the inner wall of the outer cylinder tube 1 to form an annular oil chamber 7; The piston rod 3 includes a piston part 301 and a rod part 302 connected to the bottom end of t...

Embodiment 2

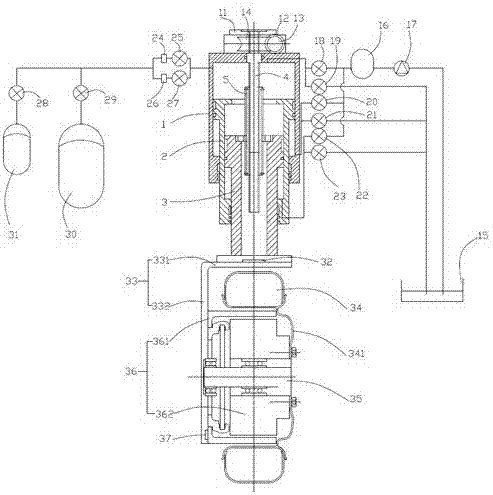

[0051] This embodiment provides a wheel steering structure, which includes the oil-gas spring provided in the first embodiment above, wherein the oil-gas spring is a spring provided with a spline shaft 4, and the top of the spline shaft 4 is connected to drive its winding A drive unit that rotates on its axis. In this embodiment, such as figure 1 with figure 2 , The drive unit preferably includes a drive motor 12, a steering worm wheel 14 and a steering worm 13, the steering worm wheel 14 is coaxially sleeved with the spline shaft 4, and the steering worm 13 meshes with the steering worm wheel 14 and Connect with the driving motor 12. Since the driving motor 12 controls the steering of the wheels through the steering worm 13 and the steering worm wheel 14, and because the worm has a certain self-locking effect on the worm wheel, it can offset the steering interference of the ground on the wheel.

[0052] In the steering structure of the wheel provided in this embodiment, the sp...

Embodiment 3

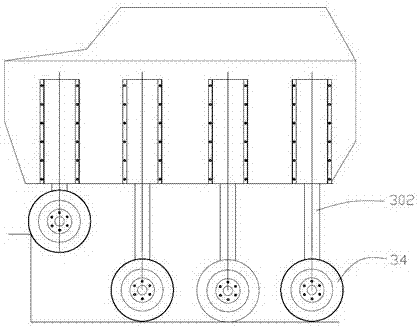

[0056] Such as figure 2 , This embodiment provides a wheel, including a wheel body 34, a wheel axle 35 and a wheel axle seat 33, the wheel axle 35 is mounted on the wheel axle seat 33 and connected to the wheel body 34, and also includes the first embodiment described above The oil-air spring provided; the axle seat 33 includes a vertical section 332 for connecting with the wheel axle 35 and a horizontal section 331 connected to the top of the vertical section 332 and extending toward the vehicle body, the rod The bottom end of the portion 302 is fixedly connected to the top end of the horizontal section 331. The above-mentioned vertical section 332 and horizontal section 331 preferably adopt a disc-shaped structure.

[0057] A further preferred solution is that the oil-air spring is a spring provided with a spline shaft 4, and the top end of the spline shaft 4 is connected with a driving unit that drives it to rotate around its own axis. For this solution, reference may be mad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com