clutch master cylinder

A clutch master cylinder and housing technology, applied in clutches, fluid-driven clutches, non-mechanical drive clutches, etc., can solve the problems that the sealant cannot withstand high pressure, the strength of the metal insert cannot be reached, and the risk of seal failure is high. Avoid surface treatment process, good injection molding process, and ensure the effect of consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, but the present invention is not limited to these embodiments.

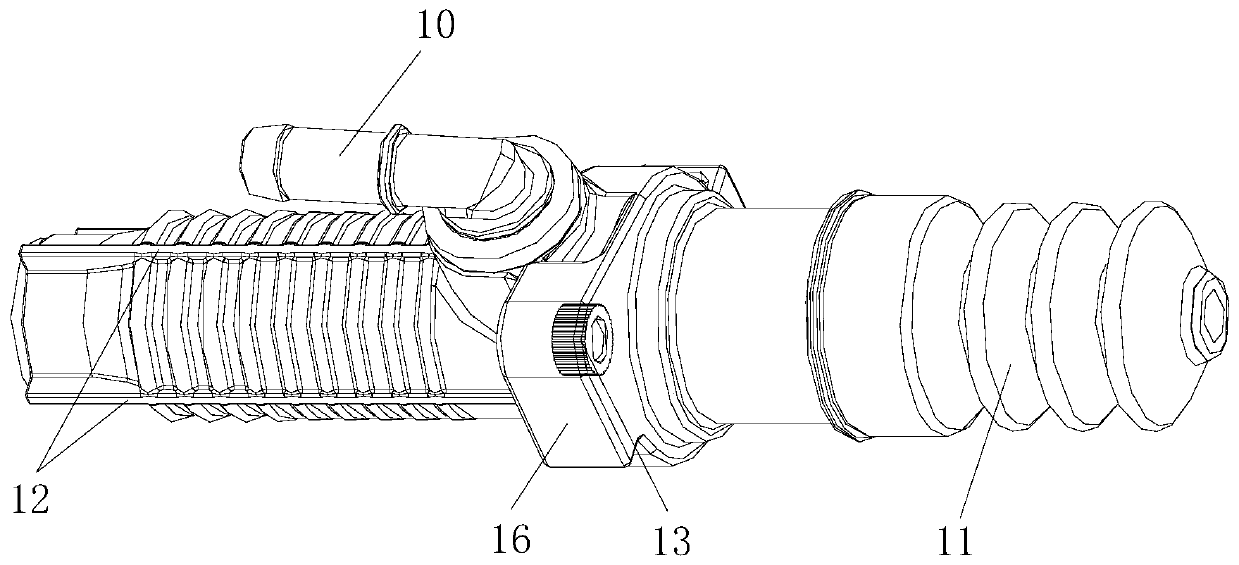

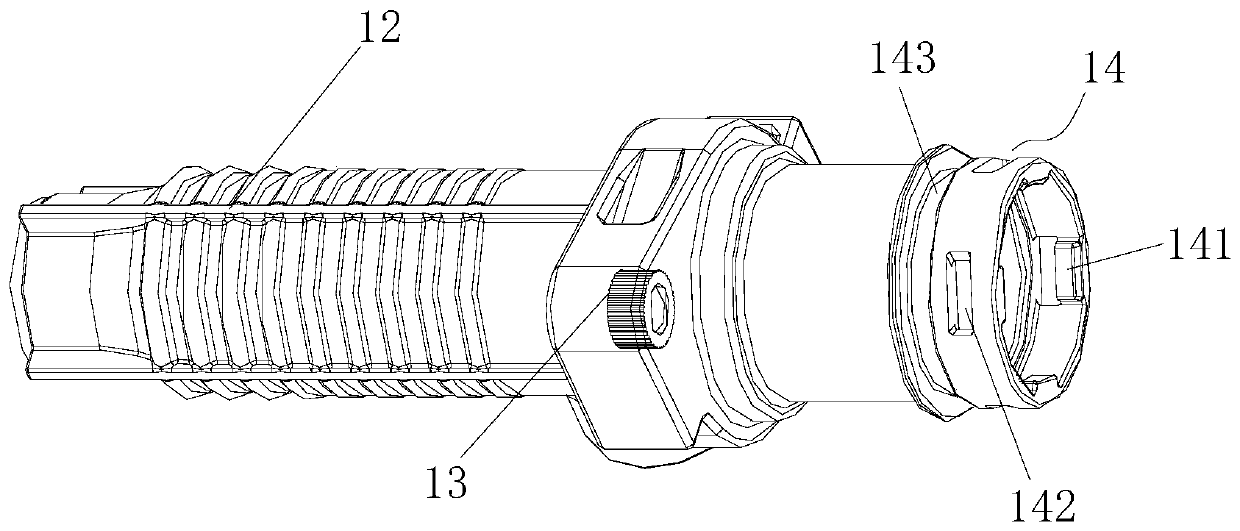

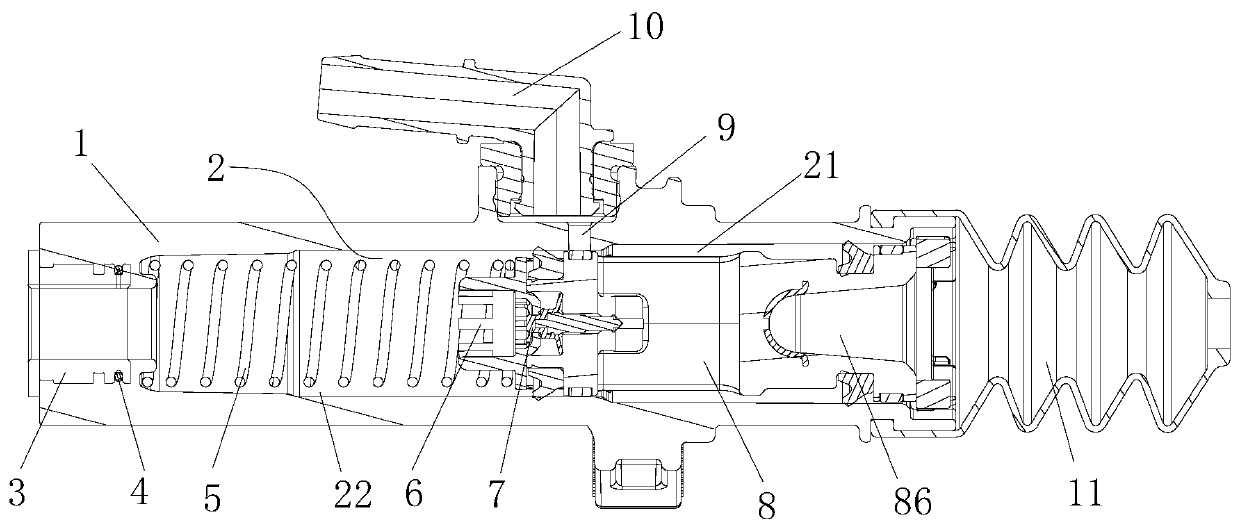

[0037] Such as Figure 1 to Figure 10 As shown, the clutch master cylinder includes a housing 1 made of plastic. A plurality of reinforcing ribs 12 are uniformly distributed along the axial direction of the housing 1 around the outer circumference of the housing 1, and the reinforcing ribs 12 are made of plastic. The outer side of the housing 1 is provided with a flange plate 16 for realizing the installation and positioning of the housing 1. The flange plate 16 is made of plastic, and the flange plate 16 is located on the right side of the reinforcing rib 12. In the positioning hole, a second metal insert 13 is arranged in the positioning hole, which ensures the installation strength. The right end of the housing 1 is provided with a dustproof cover 11 connected thereto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com