Flange end face grinding device

An end face and grinding bar technology, applied in the direction of grinding drive device, grinding machine, grinding frame, etc., can solve the problem of low practicability, and achieve the effect of strong practicability, convenient operation and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below by means of specific embodiments:

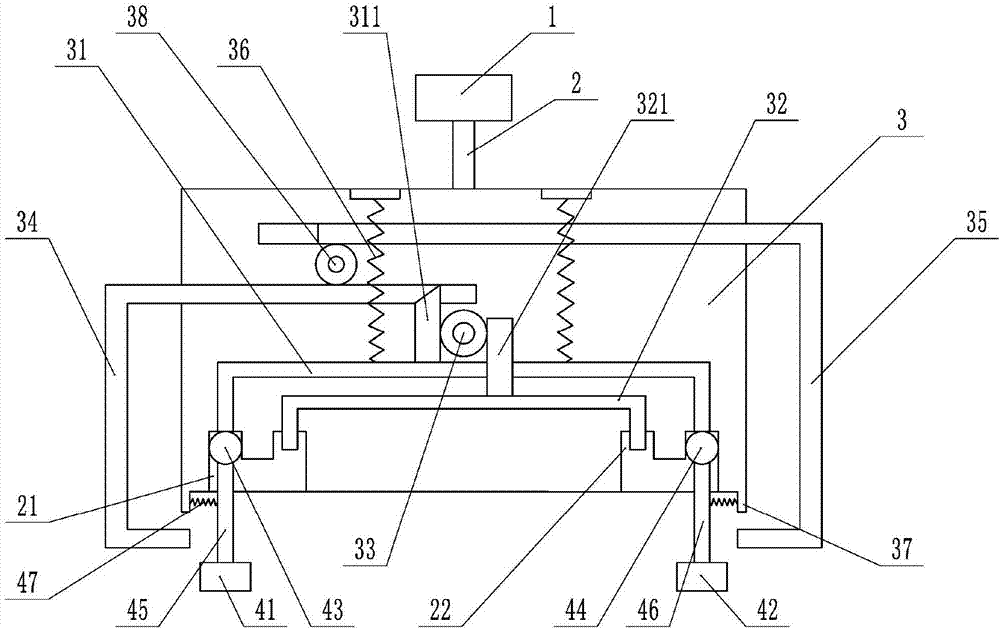

[0019] The reference signs in the drawings of the description include: motor 1, rotating shaft 2, first positioning groove 21, second positioning groove 22, rotary table 3, first fixed rod 31, first wedge rod 311, second fixed rod 32, Rack 321, first gear 33, second wedge bar 34, connecting rod 35, first spring 36, flange 37, second gear 38, first grinding bar 41, second grinding bar 42, first ball 43, The second ball 44 , the first push rod 45 , the second push rod 46 , and the second spring 47 .

[0020] Such as figure 1 As shown, the flange end face grinding device includes a motor 1, a rotating shaft 2, a rotating table 3, a first grinding bar 41 and a second grinding bar 42, the motor 1 is located above the rotating table 3, and the rotating shaft 2 is welded to the output of the motor 1 On the shaft, the lower end of the rotating shaft 2 is welded with the rotary ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com