Method for improving uniformity of general performance of rolled wire rod

A uniformity and wire rod technology, which is applied in the field of improving the uniformity of the performance of the rolled wire rod, can solve the problems of the fluctuation of the tensile strength of the rod, and achieve the effect of reducing the cost of wire drawing, simple and easy to implement, and reducing the tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In the following, the present invention will be further described in detail in combination with examples and comparative examples. The embodiment and the comparative example all adopt a walking heating furnace-high pressure water dephosphorization-multi-pass high-speed rolling-spinning-stelmore delayed cooling technology route. During the cooling process, the insulation cover is all closed, the fans are all closed, and the cooling After the set volume.

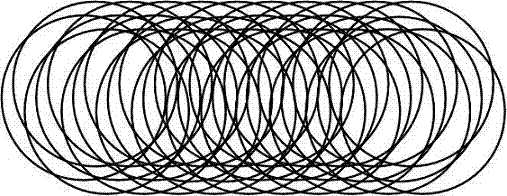

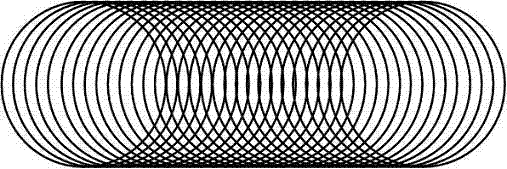

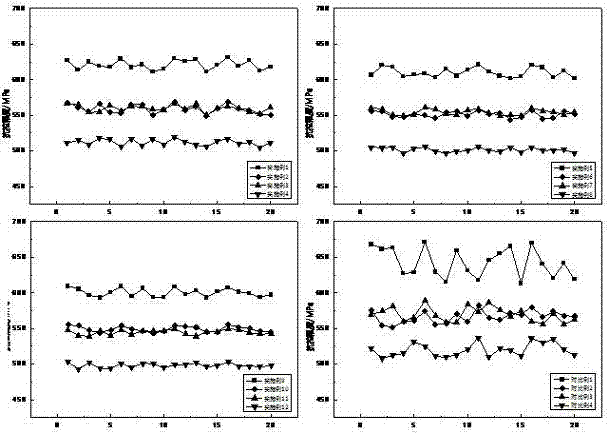

[0025] 1. Example 1 was implemented in 600MPa grade wire. The spinning tube is used for the first time, the spinning temperature meets Ts=Fs+98℃±10℃, the initial section roller table speed Vs=0.13m / s, the initial section of the Stelmore cooling roller table can be perpendicular to the forward direction of the roller table Do reciprocating motion, length 1.5m, reciprocating motion frequency 50 times / min, amplitude 0.15m;

[0026] 2. Example 2 was implemented in a 550MPa grade wire. The spinning tube is used for the first t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com