Method for preparing nickel-based composite metallic oxide ceramic air filter

An oxide ceramics, air filter technology, applied in chemical instruments and methods, membrane filters, chemical/physical processes, etc., can solve the problems of low activity performance, low product use satisfaction, low work efficiency, etc. Wide range, permanent maintenance-free use, and the effect of avoiding resource waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

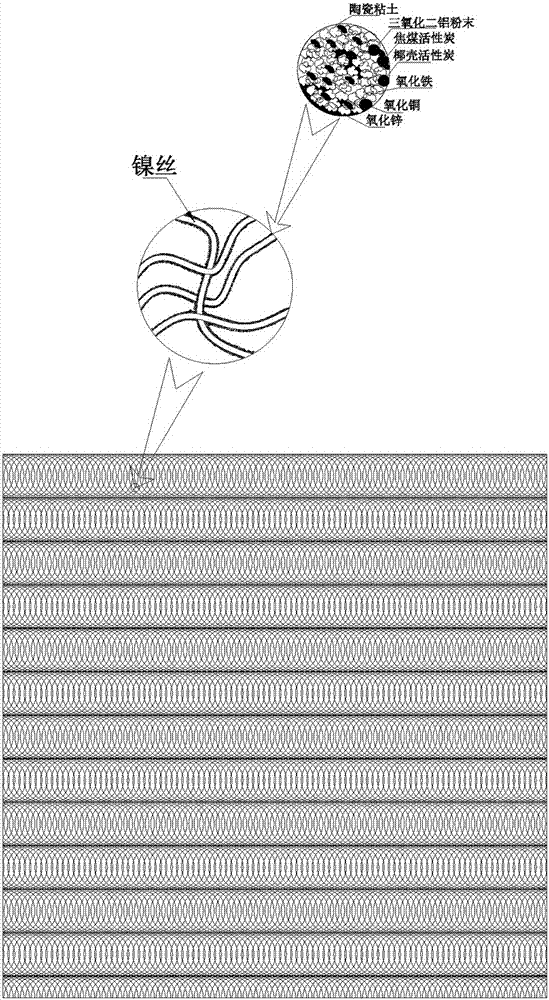

[0015] Such as figure 1 As shown, the mass ratio of the nickel-based composite metal oxide consists of the following components, including Al 2 o 3 Zeolite molecular sieve powder 32%, coking coal powder 11%, coconut shell powder 11%, ceramic clay 6%, organic plasticizer 2%, citric acid 1%, water 35%, Fe 2 o 3 1%, CuO 0.5%, ZnO 0.5%.

[0016] Coking coal and coconut shells are pulverized and milled, and the coking coal and coconut shells are crushed and ground separately to achieve particles with a particle size of 0.05mm, and then dried at 130°C for 2 hours for later use. The composite of charcoal is activated carbon functional powder, which realizes the moisture-resistant and long-lasting activation shape and adsorpt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com