Blade ejector measuring tool

The technology of inspection tool and flat top is applied in the field of mold standard parts inspection devices, which can solve the problems of low inspection efficiency and wrong inspection results, and achieve the effects of high inspection efficiency, simple structure and reasonable design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

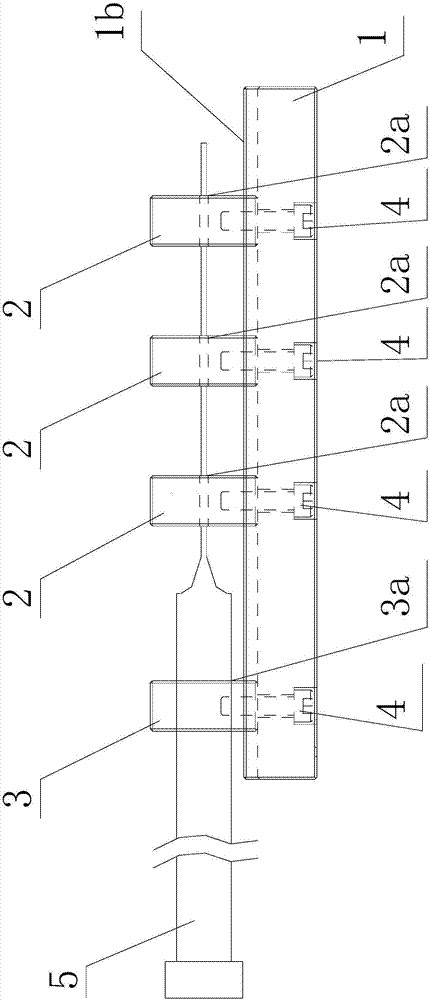

[0015] What needs to be explained here is that the direction words left, right, up and down are all based on figure 2 The view shown is a baseline definition, and it should be understood that the use of the location words should not limit the scope of protection requested by this application.

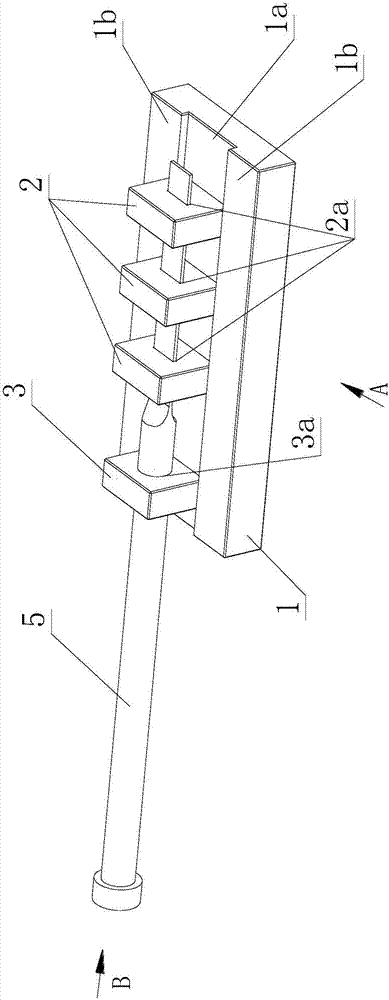

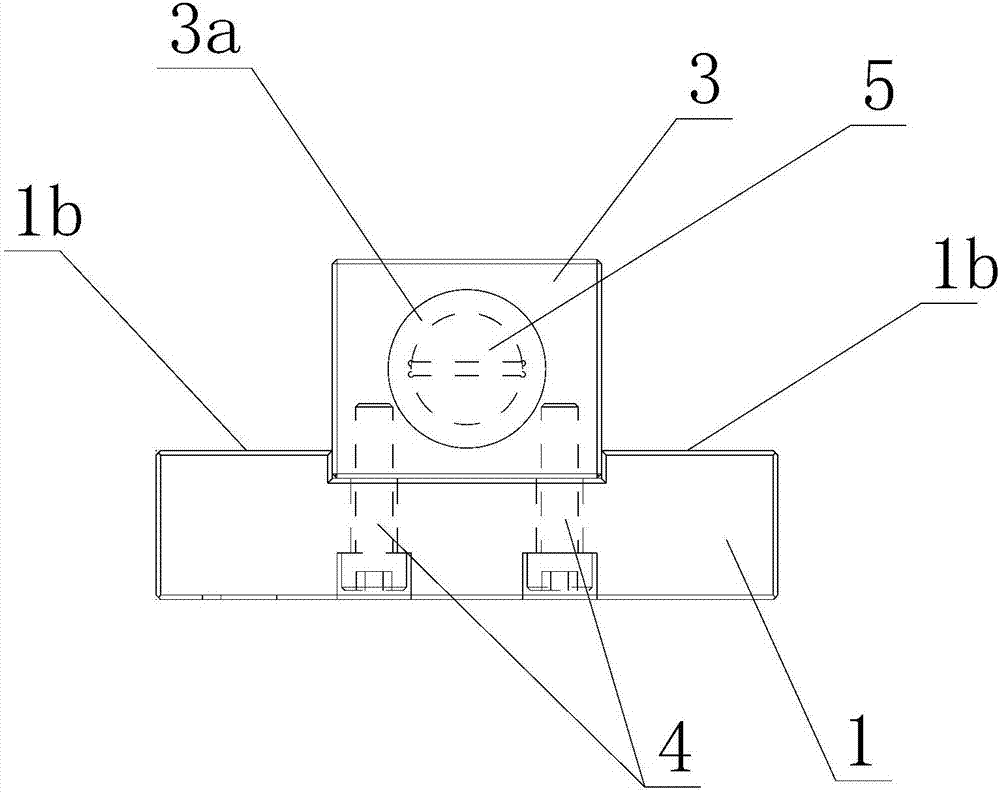

[0016] The present invention will be further described below in conjunction with the drawings and embodiments. Such as Figure 1 to Figure 3 As shown, a flat ejector rod inspection tool includes a tooling body 1. The tooling body 1 is provided with a clamping groove 1a along the length direction at the upper end thereof, and a limiting protrusion 1b is provided on both sides of the clamping groove 1a. A round rod gauge block 3 and a plurality of flat position gauge blocks 2 are clamped in the clamping groove 1a from left to right. The center of the round rod gauge block 3 is provided with a round rod measuring hole 3a. The center of the position measuring block 2 is provided with a flat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com