Device and process for treating waste gas of vanadium-titanium reducing rotary kiln

A technology of rotary kiln and waste gas, applied in the field of waste gas treatment of vanadium-titanium pre-reduction rotary kiln, can solve the problems of difficult stable and complete combustion of waste gas and low combustible content, and achieve the effect of lowering temperature, easy engineering realization and reducing impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

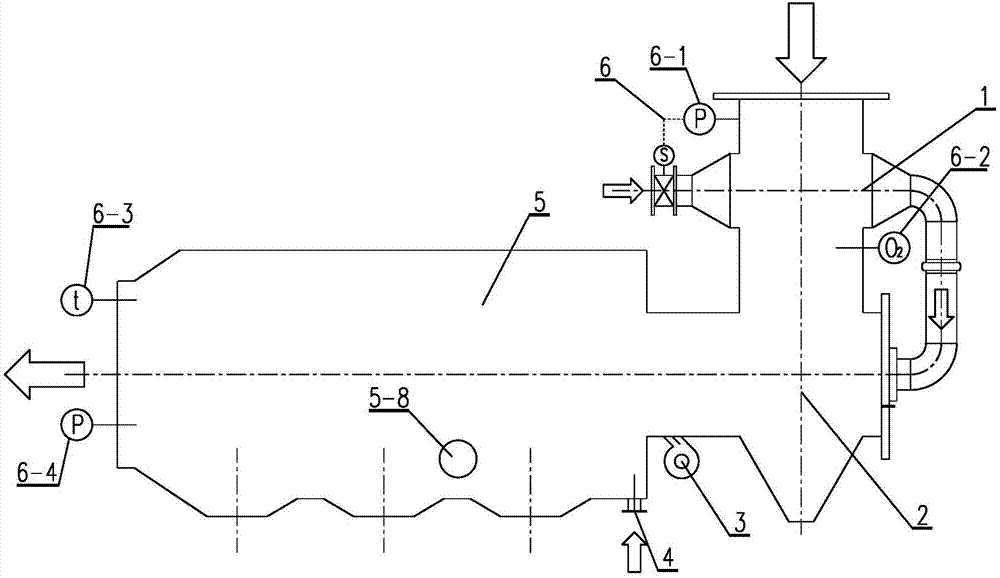

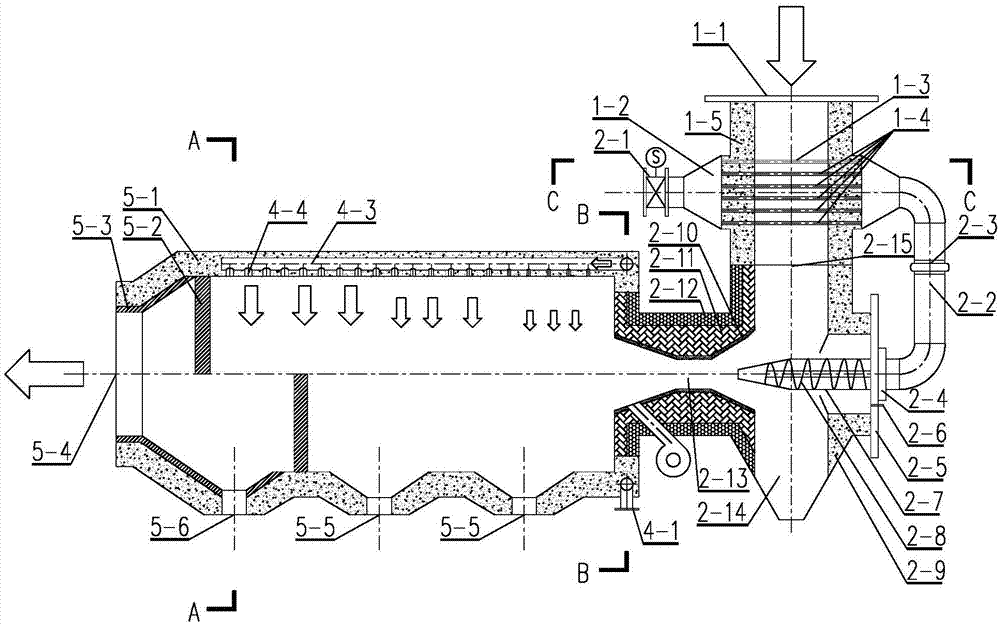

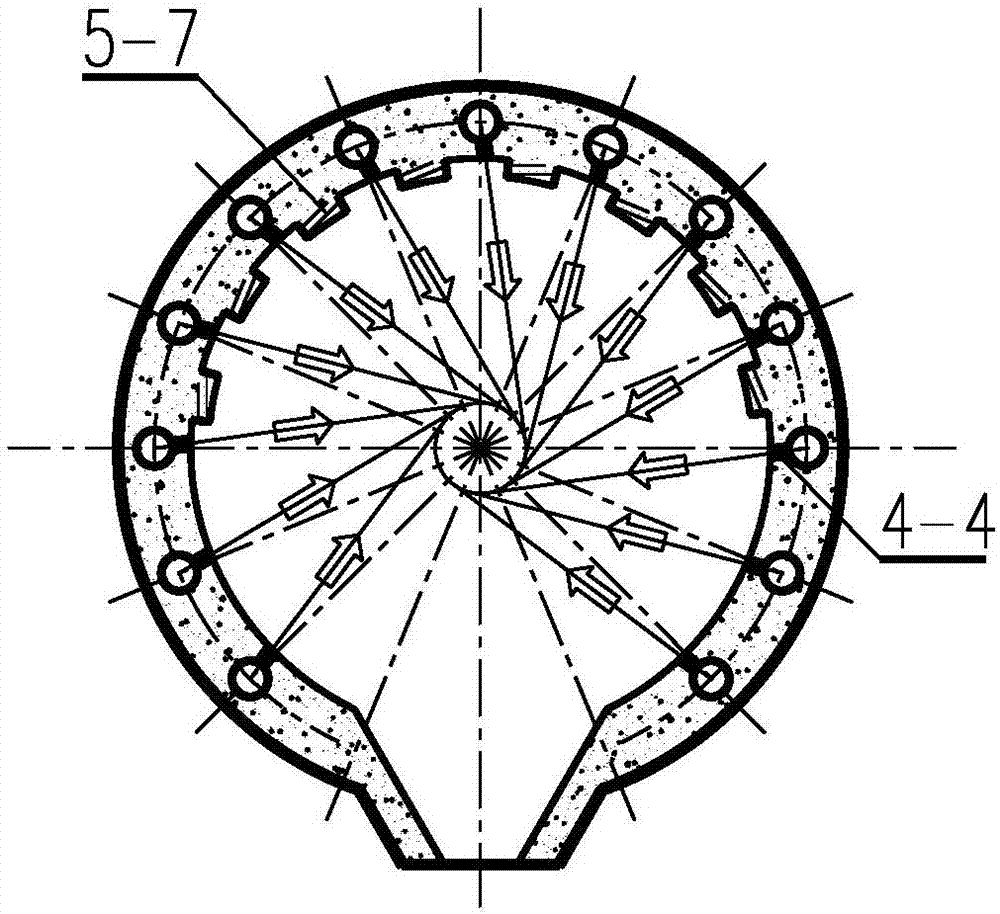

[0033] See Figure 1-Figure 5 , a device for treating waste gas from a vanadium-titanium reduction rotary kiln, including a high-temperature waste gas cooling device 1, a primary air injection device 2, an ignition stable combustion heat storage device 3, a secondary air device 4, a combustion chamber 5, and a throat mixing zone 2 -13, the exhaust gas channel of the high-temperature exhaust gas cooling device 1 communicates with the exhaust gas channel of the primary air ejection device 2, and the exhaust gas channel of the primary air ejection device 2 communicates with the combustion chamber 5 through the throat mixing zone 2-13, the The secondary air device 4 is circumferentially arranged in the inner wall of the combustion chamber 5; the primary air inlet of the primary air ejection device 2 is connected to the tubular heat exchanger of the hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com