Composite packaging film and preparation method thereof

A composite packaging film and protective film technology, applied in textiles and papermaking, fiber raw material processing, paper coating, etc., to achieve the effect of slowing down the melting speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

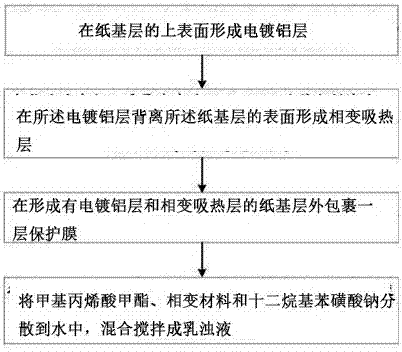

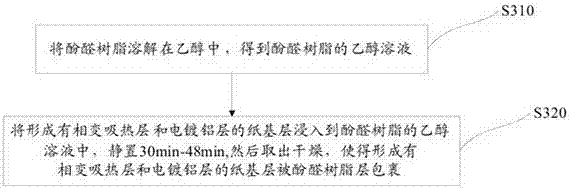

[0019] like figure 1 and Figure 4 As shown, the embodiment of the present invention provides a preparation method of a composite packaging film, comprising the following steps:

[0020] The first step is to form an electroplated aluminum layer 2 on the upper surface of the paper base layer 1;

[0021] In the second step, a phase change heat absorbing layer 3 is formed on the surface of the electroplated aluminum layer 2 away from the paper base layer 1;

[0022] In the third step, a protective film 4 is wrapped around the paper base layer formed with the electroplated aluminum layer 2 and the phase change heat absorbing layer 3 .

[0023] Based on the preparation method of the above-mentioned composite packaging film, the upper surface of the paper base layer 1 forms an electroplated aluminum layer 2, and the surface of the electroplated aluminum layer 2 away from the paper base layer 1 forms a phase change heat absorption layer 3. When using this composite packaging film t...

Embodiment 1

[0047] The preparation method of the composite packaging film provided by the embodiment of the present invention comprises the following steps:

[0048] The first step is to form an electroplated aluminum layer 2 on the upper surface of the paper base layer 1;

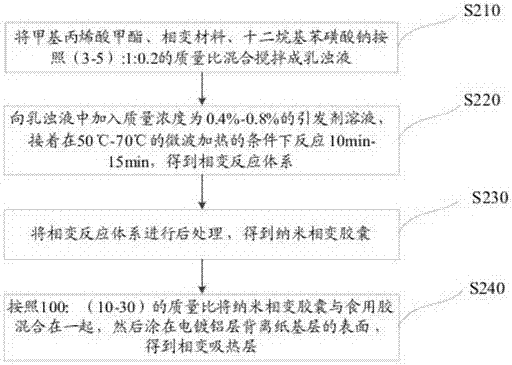

[0049] In the second step, methyl methacrylate, liquid paraffin and sodium dodecyl benzene sulfonate are dispersed in water, mixed and stirred to form an emulsion; wherein, methyl methacrylate, liquid paraffin and dodecyl benzene sulfonate The mass ratio of acid is 3:1:0.2; the solid content of the emulsion is 60%;

[0050] A potassium persulfate aqueous solution with a mass concentration of 0.4% was added to the emulsion, and then reacted under the condition of microwave heating at 50 ° C for 15 min to obtain a phase change reaction system; the quality of potassium persulfate in the potassium persulfate aqueous solution was the same as the The mass ratio of methyl methacrylate is 1:100;

[0051] Saturated brine was...

Embodiment 2

[0057] The preparation method of the composite packaging film provided by the embodiment of the present invention comprises the following steps:

[0058] The first step is to form an electroplated aluminum layer 2 on the upper surface of the paper base layer 1;

[0059] In the second step, methyl methacrylate, liquid paraffin and sodium dodecyl benzene sulfonate are dispersed in water, mixed and stirred to form an emulsion; wherein, methyl methacrylate, liquid paraffin and dodecyl benzene sulfonate The mass ratio of acid is 4:1:0.2; the solid content of the emulsion is 70%;

[0060] Add the azobisisobutyronitrile aqueous solution with a mass concentration of 0.8% to the emulsion, and then react under the condition of microwave heating at 70 ° C for 10 min to obtain a phase change reaction system; The mass ratio of diisobutyronitrile to methyl methacrylate is 1:150;

[0061] Saturated brine was added to the phase change reaction system to break the phase change reaction syste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com