Catalyst packing structure for isobutene oligomerization

A catalyst and isobutylene technology, which is applied in the field of isobutylene superimposed catalyst loading structure, can solve the problems of short catalyst life, poor economic benefits, difficult loading and unloading, etc., and achieve the effects of reducing reaction temperature rise, prolonging service life and reducing side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

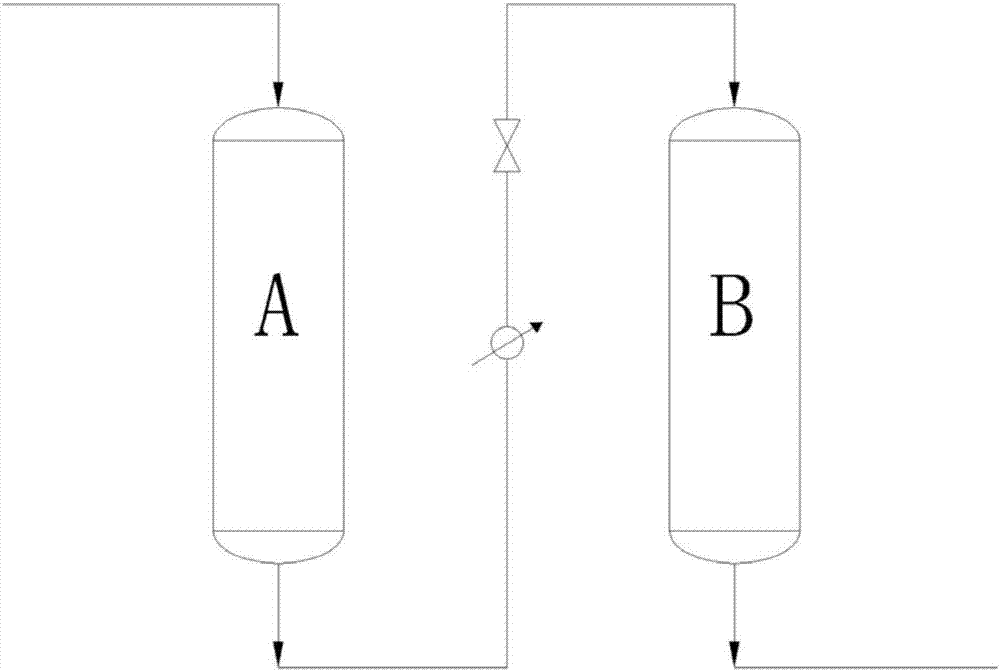

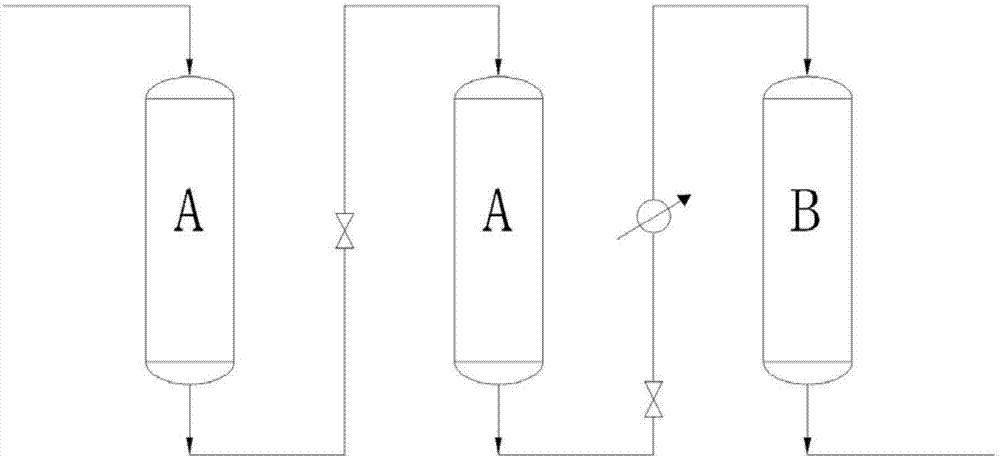

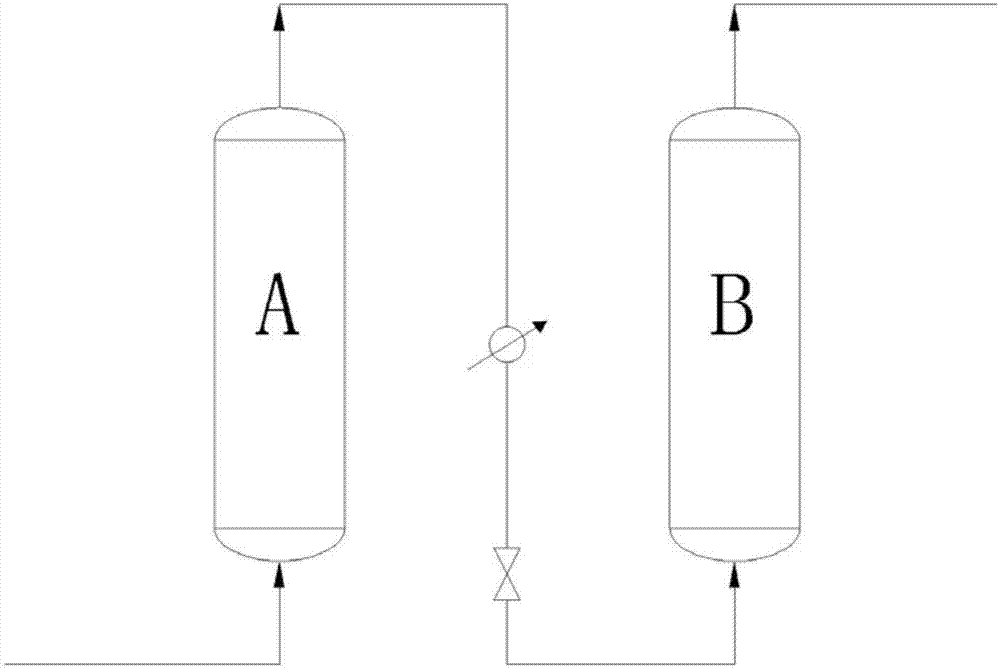

Method used

Image

Examples

Embodiment 1

[0028] Present embodiment 1: fill temperature-resistant type strong acid cationic resin exchange catalyst A in the first and second reactors 1 and 2 of the present invention, fill normal temperature type strong acid cationic resin exchange catalyst B in the third reactor 3, and the result is:

[0029] 1. The service life of the catalyst is 12 months;

[0030] 2. The conversion rate of isobutylene is ≥75%, and the selectivity of dimerized isobutylene is ≥95%.

[0031] The technical scheme of this application is applied to other commercially available normal temperature type strong acid cation resin exchange catalysts and temperature-resistant type strong acid cation resin exchange catalysts. After repeated experiments and comparisons, the stacking reaction operation of this scheme has an average service life of the exchange resin catalysts. Compared with single use of normal temperature type strong acid cation resin exchange catalyst and temperature resistant type strong acid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com