Injection tube cutting device

A technology for cutting devices and injection-molded pipes, applied in metal processing, etc., which can solve the problems of time-consuming and laborious, high requirements for workers and equipment, and inability to process injection-molded pipes of different specifications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following is further described in detail through specific implementation methods:

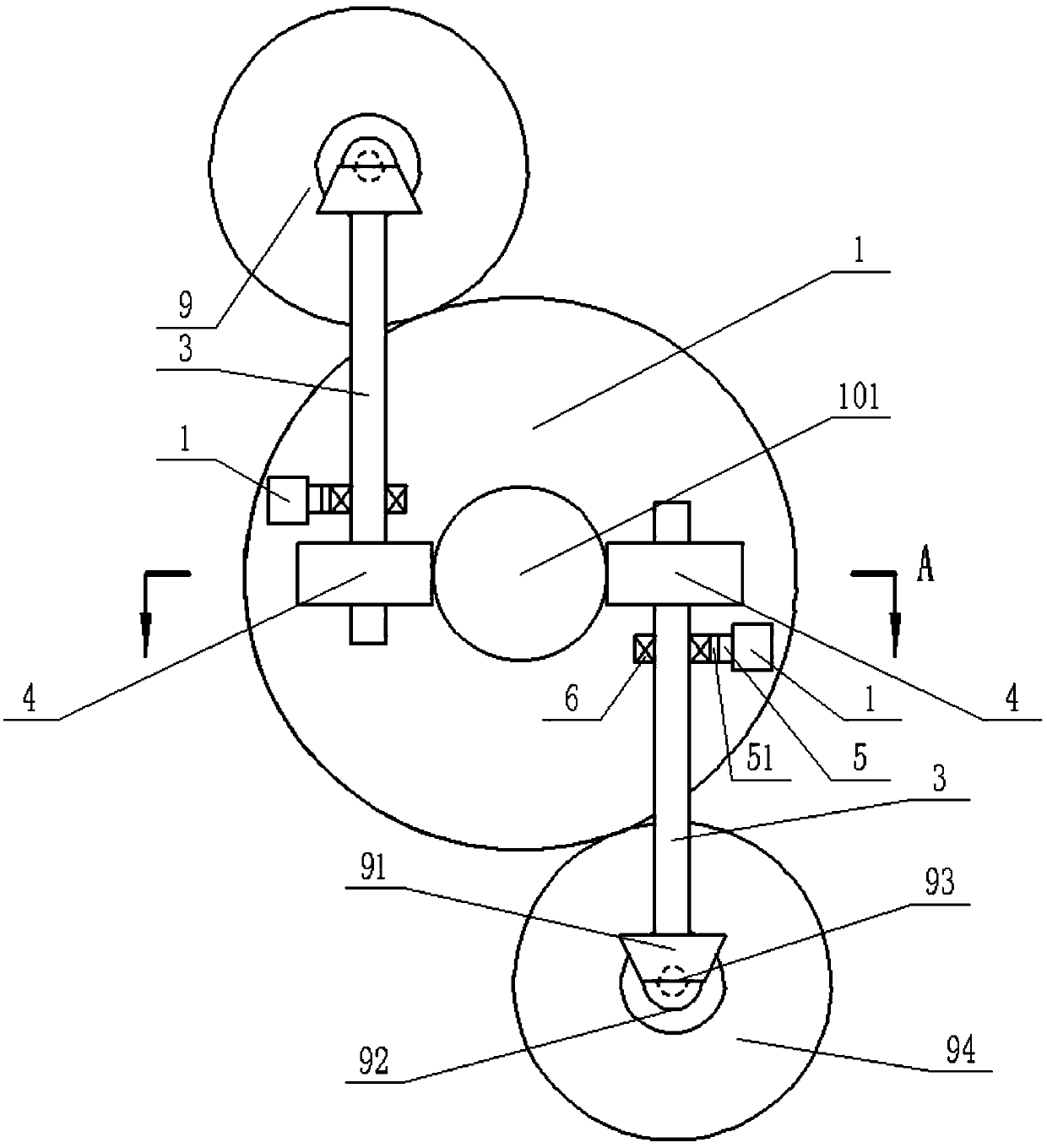

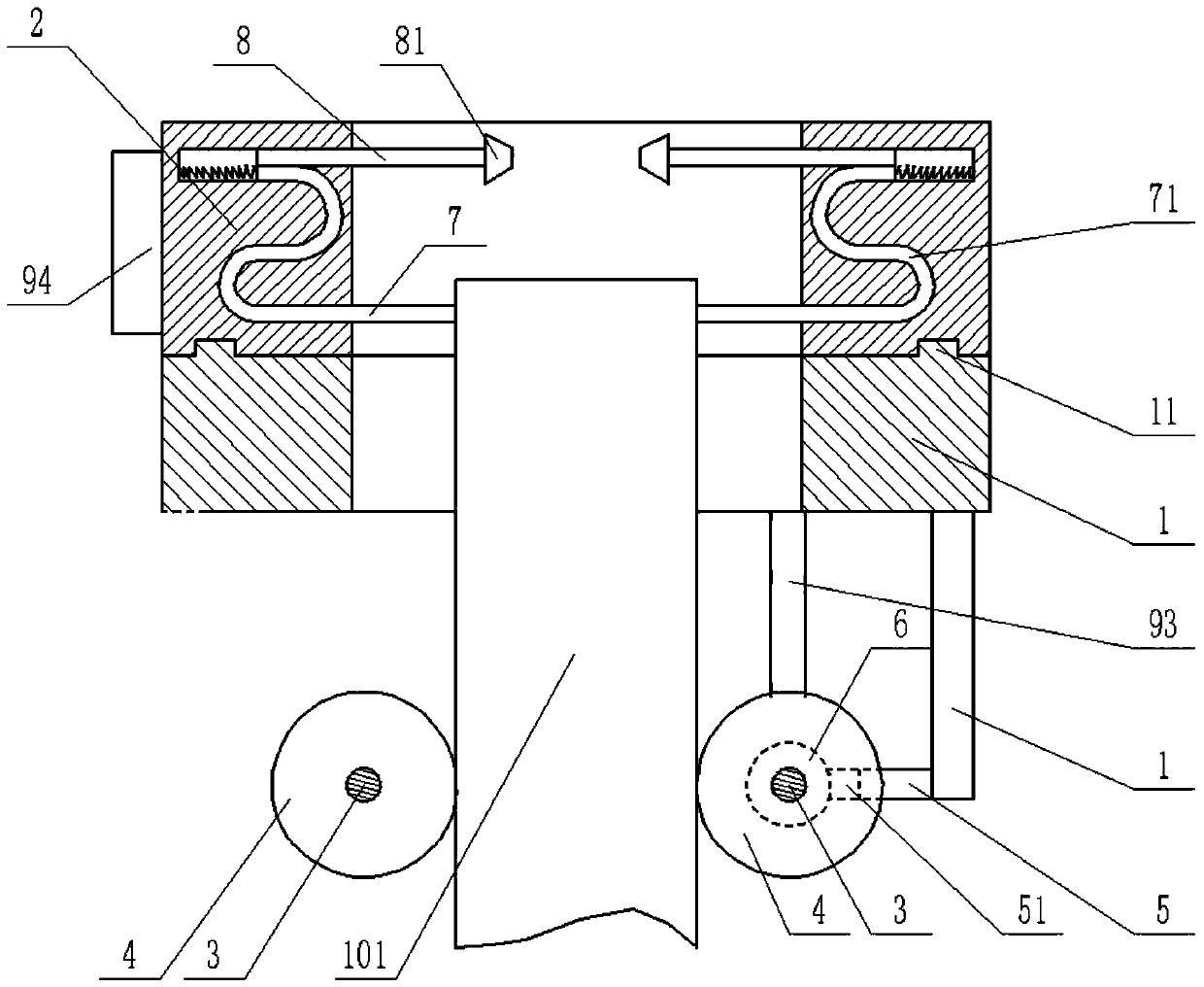

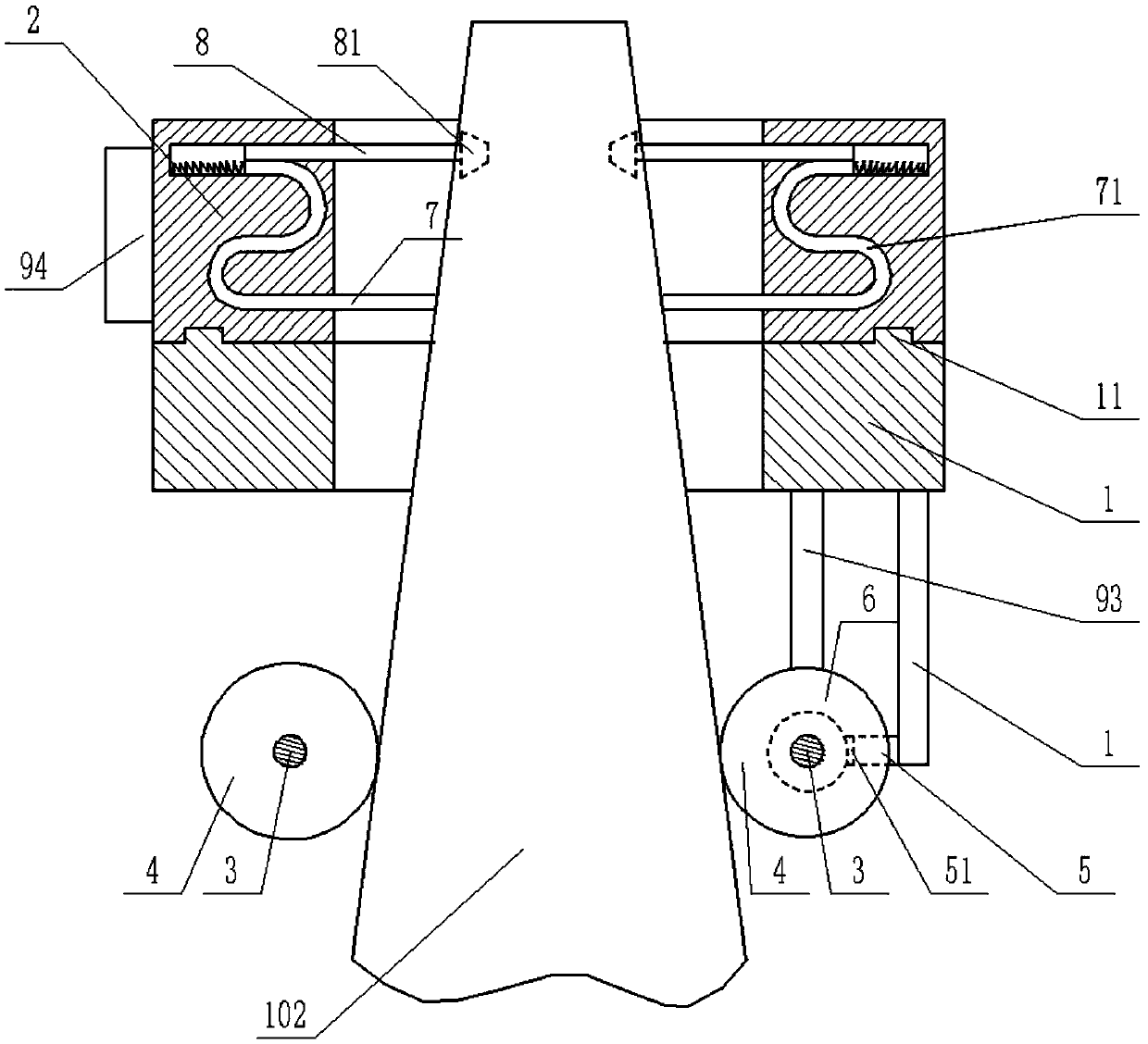

[0029] The reference signs in the drawings of the description include: processing table 1, protrusion 11, first external gear 2, rotating shaft 3, friction wheel 4, telescopic rod 5, telescopic end 51, bearing 6, hard tube 7, S-shaped channel 71. Knife rest 8, cutter 81, transmission unit 9, first bevel gear 91, second bevel gear 92, transmission shaft 93, second external gear 94, injection molding tube 101, tapered injection molding tube 102.

[0030] The embodiment is basically as attached figure 1 , figure 2 As shown: the injection molding pipe cutting device includes a cylindrical processing table 1 and a first external gear 2, the processing table 1 is vertically arranged, the first external gear 2 is coaxially connected to the upper end surface of the processing table 1, and the first The lower end surface of the external gear 2 is provided with an annular groove along the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com