Matrix type adjustable sheet metal deformation device

A deformation device and adjustable technology, which is applied in the field of matrix adjustable sheet metal deformation devices, can solve the problems of pure manual sheet metal repairs that cannot meet market demand, rough body shell repairs, and unsatisfactory repair effects, etc., to achieve sheet metal repairs Good effect, avoid time-consuming and labor-intensive, high-precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is further described below in conjunction with accompanying drawing:

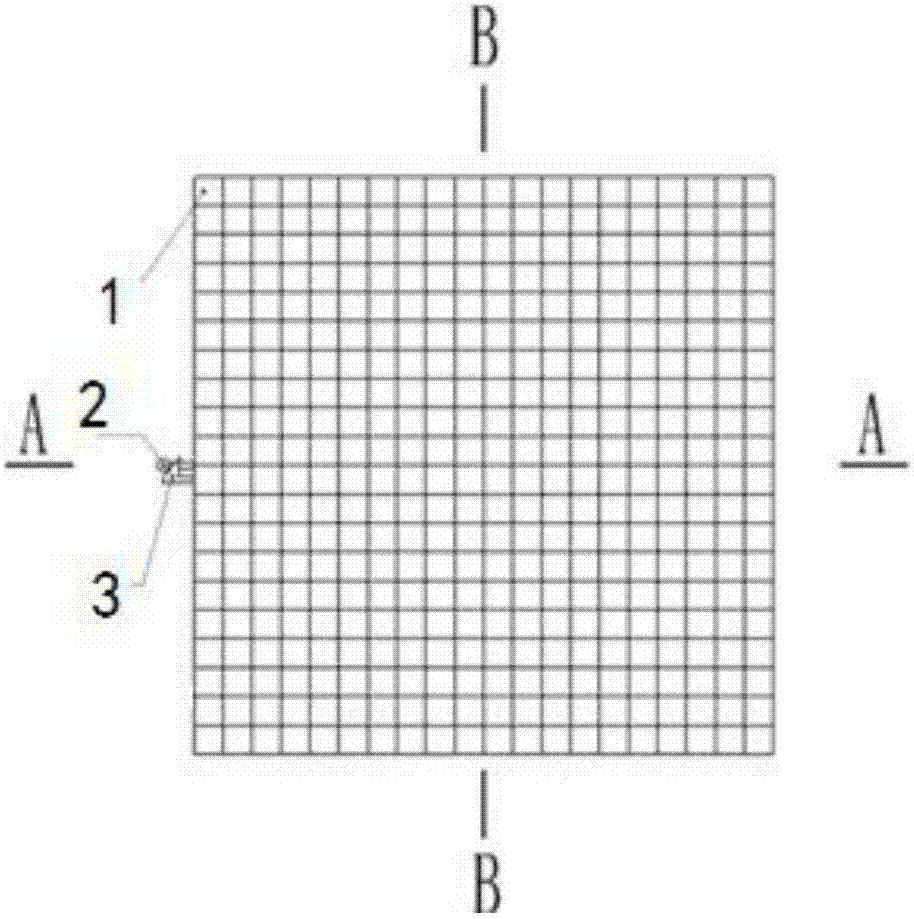

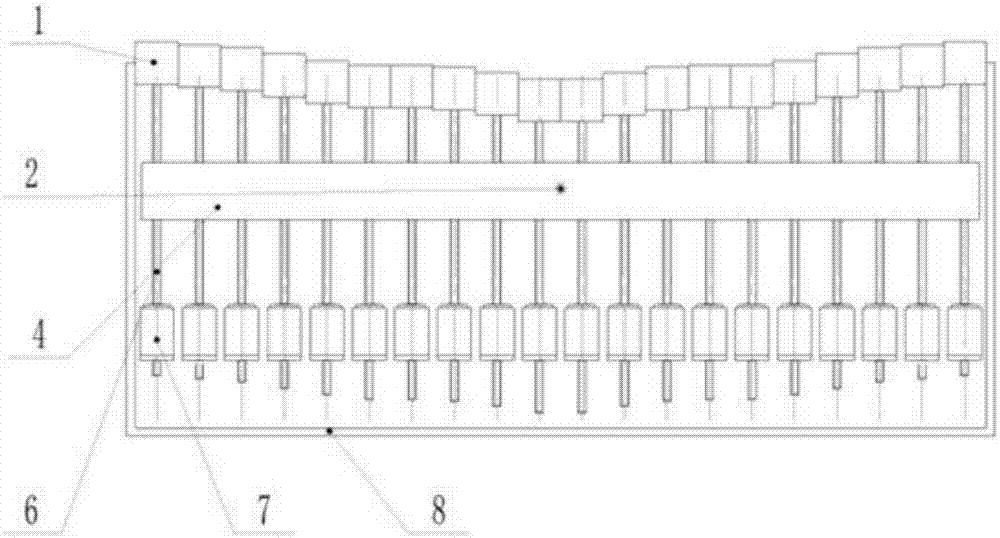

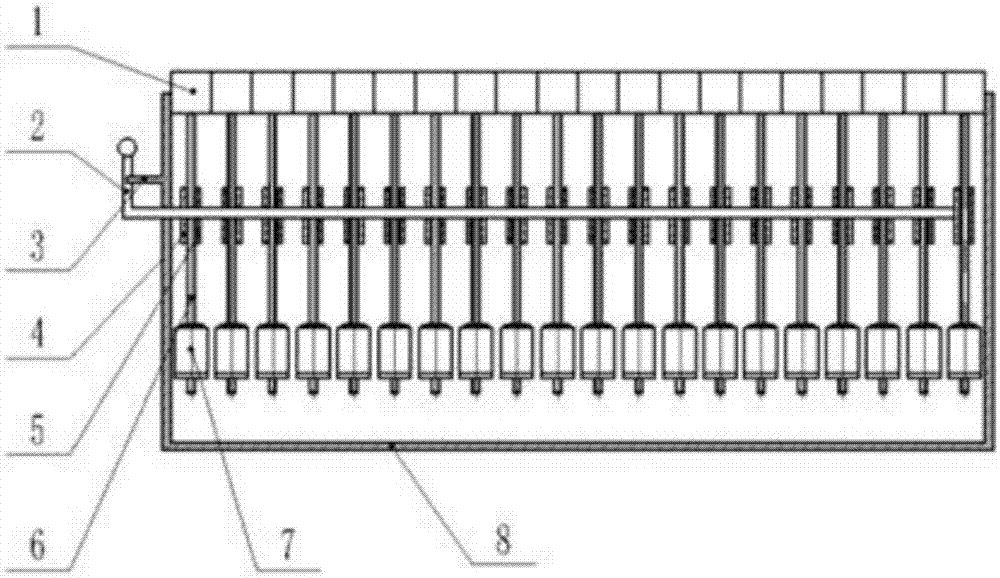

[0019] A matrix-type adjustable sheet metal deformation device, including a casing 8, an operation block 1, a screw 6, a motor 7 and a clamping device; the casing 8 is a box with an open top, and several Motor 7; lead screw 6 is arranged on the motor 7, and the rotation of motor 7 drives lead screw 6 to reciprocate up and down; lead screw 6 vertically faces the opening direction of shell 8, and the top of lead screw 6 is fixedly provided with operation block 1, several operations The blocks 1 are arranged side by side to form a matrix completely covering the top opening of the shell 8; the lead screw 6 is provided with a clamping device.

[0020] The casing 8 is a box with a rectangular cross section, and the motors 7 are arranged side by side, and each row of motors 7 is parallel to the inner wall of the casing 8; the clamping device includes an operating rod 2, a clamping plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com