Pulse cleaner for integrated hoisting

A technology of cleaner and pulse, which is applied in the directions of transportation and packaging, chemical instruments and methods, and separation of dispersed particles. It can solve problems such as loosening of the boom, poor pulse effect, and dispersal, so as to overcome the loosening of the boom and eliminate powder leakage. Phenomenon, effect of enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

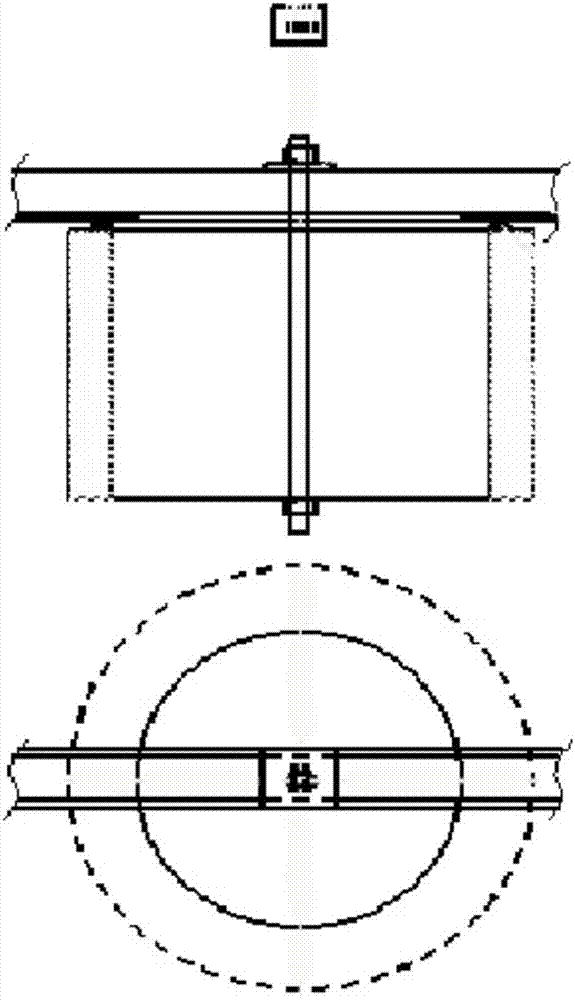

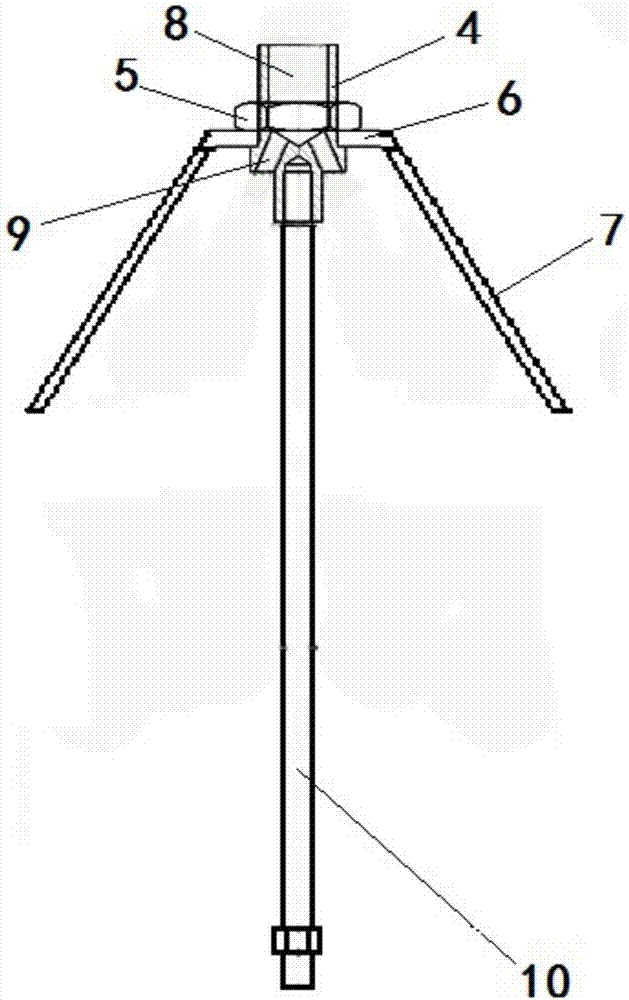

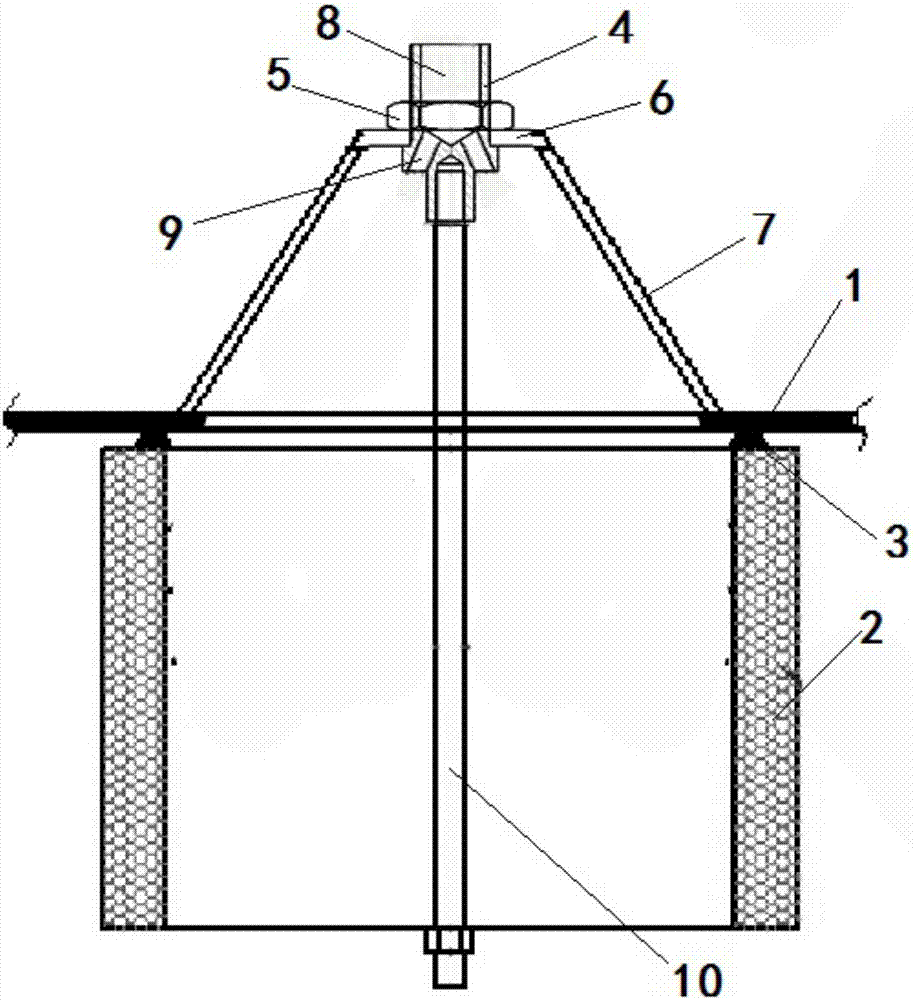

[0016] Such as figure 2 As shown, a pulse cleaner for integrated hoisting includes a flow divider 4, the side of the flow divider 4 is fixed on a bracket 6 by bolts 5, and a circle of guide rings is fixed obliquely downward on the outer periphery of the bracket 6 7. The top center of the splitter 4 is provided with an air inlet 8 vertically, and the bottom edge is provided with a plurality of outlet holes 9, and the outlet holes 9 are evenly distributed around the circumference, and each outlet hole 9 is connected to the The air intake hole 8 is connected, the bottom of the flow divider 4 is fixed with a vertical rod 10, the side of the flow divider 4 is a stepped shape with a small upper part and a large lower part, and the support 6 is provided with The hole matching the upper part, the upper outer side of the splitter 4 is provided with a thread, and a nut matching the thread is provided, the bracket 6 is fastened on the splitter 4 through the nut, and the air outlet hole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com