Three-dimensional high-thermal-conductivity and high-electrical-conductivity composite material, preparation method thereof and application thereof

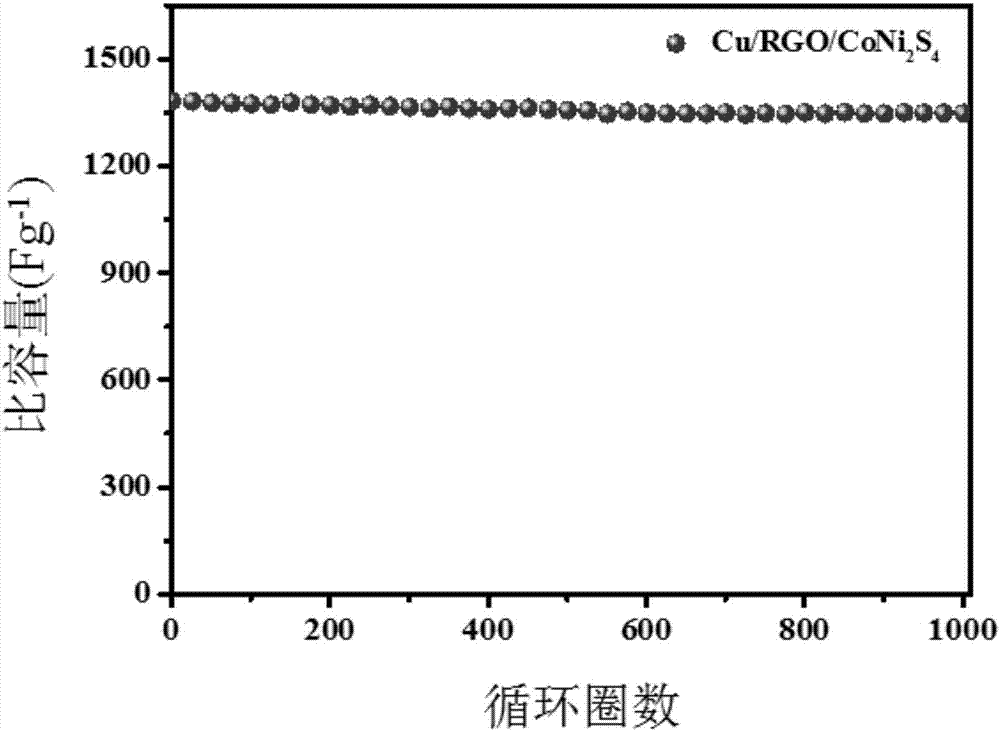

A composite material, three-dimensional technology, applied in the field of preparation of new inorganic non-metallic materials, can solve the problems of inability to dissipate heat, the electrode is prone to generate a large amount of heat, and the device stability and safety are unfavorable.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] (1) Graphene oxide was prepared by the improved Hummer method. Prepare a 2 mg / ml graphene oxide solution.

[0062] (2) 2mg / ml graphene oxide solution was used as the electrolyte, the copper foam was connected to the positive electrode of the power supply, and the platinum sheet electrode was connected to the negative electrode, and electrodeposition was performed at a constant voltage of 3V for 10 minutes. The reduced graphene physically adsorbed on the surface of the electrode was rinsed away, and the electrode was put into a vacuum oven to dry overnight to obtain a copper foam deposited with reduced graphene, that is, a three-dimensional framework.

[0063] (3) Weigh 0.012g of CoCl 2 ·6H 2 O, 0.178g NiCl 2 ·6H 2 O and the thiourea of 5.6g, and they are dissolved in the deionized water of 100ml, obtain mixed solution.

[0064] (4) With the copper foam that deposited the reduced graphene as working electrode, platinum plate is counter electrode, Ag / AgCl electrode...

Embodiment 2

[0070] (1) Graphene oxide was prepared by the improved Hummer method. Prepare a 2 mg / ml graphene oxide solution.

[0071] (2) 2mg / ml graphene oxide solution was used as the electrolyte, the copper foam was connected to the positive electrode of the power supply, and the platinum sheet electrode was connected to the negative electrode, and electrodeposition was performed at a constant voltage of 5V for 5min. The reduced graphene physically adsorbed on the surface of the electrode was rinsed away, and the electrode was put into a vacuum oven to dry overnight to obtain a copper foam deposited with reduced graphene, that is, a three-dimensional framework.

[0072] (3) Weigh 0.012g of CoCl 2 ·6H 2 O, 0.178g NiCl 2 6H2O and 5.6 g of thiourea were dissolved in 100 ml of deionized water to obtain a mixed solution.

[0073] (4) With the copper foam that deposited the reduced graphene as working electrode, platinum plate is counter electrode, Ag / AgCl electrode is reference electrode...

Embodiment 3

[0076](1) Graphene oxide was prepared by the improved Hummer method. Prepare a 1 mg / ml graphene oxide solution.

[0077] (2) 1 mg / ml graphene oxide solution was used as the electrolyte, the copper foam was connected to the positive electrode of the power supply, and the platinum sheet electrode was connected to the negative electrode, and electrodeposition was performed at a constant voltage of 5V for 5 minutes. The reduced graphene physically adsorbed on the surface of the electrode was rinsed away, and the electrode was put into a vacuum oven to dry overnight to obtain a copper foam deposited with reduced graphene, that is, a three-dimensional framework.

[0078] (3) Weigh 0.012g of CoCl 2 ·6H 2 O, 0.178g NiCl 2 ·6H 2 O and the thiourea of 5.6g, and they are dissolved in the deionized water of 100ml, obtain mixed solution.

[0079] (4) With the copper foam that deposited the reduced graphene as working electrode, platinum plate is counter electrode, Ag / AgCl electrode ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com