Impact and thermal compounding test device for fiber-reinforced compound thin-walled component

A technology of fiber-reinforced composite and thin-walled components, which is applied in the testing of machines/structural components, measuring devices, vibration testing, etc. It can solve the problems of inability to apply large impact, insufficient compact structure, small thrust, etc., and achieve accurate measurement of vibration Data and impact results, the size of the impulse is convenient to control, and the effect of stable working ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

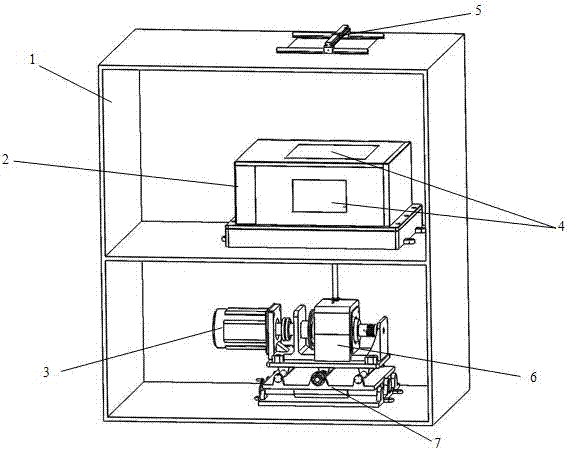

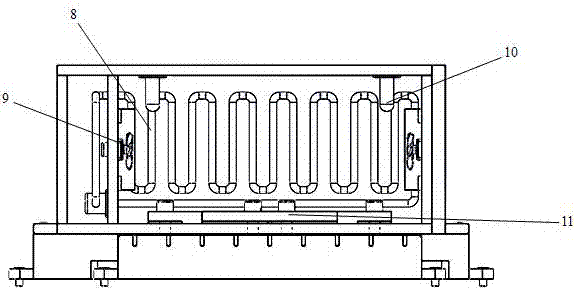

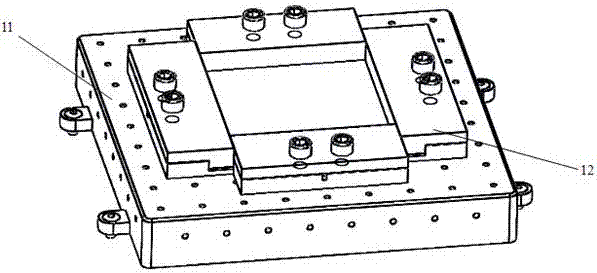

[0019] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail, as Figure 1~Figure 5 As shown, an impact and heat composite test device for fiber reinforced composite thin-walled components includes an outer box 1, a base 7 and a test box 2 arranged in the outer box 1, and a motor 3 arranged on the base 7, a rotating Accelerator 6 and conduit 13, the housing of described motor 3 is fixedly arranged on base 7, the output shaft of motor 3 is connected the power input shaft of rotary accelerator 6, and described rotary accelerator 6 comprises the motor that is fixedly arranged on base 7 The casing and the driving rotor 15 and driven rotor 16 arranged in the casing, the driving rotor 15 is fixedly sleeved on the power input shaft, the driven rotor 16 can slide axially relative to the driving rotor 15, and the driven rotor shaft is set There is an electromagnetic separator 14, the active rotor 15 and the driven rotor 16 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com