Interlocked insulating decorating wall panel and mounting and construction method thereof

An interlocking, wall panel technology, applied in covering/lining, building, building structure, etc., can solve the problems of high height, need to set up scaffolding or hanging baskets on the outside, difficult to implement in high-rise buildings, and difficult to recycle and reuse. , to achieve the effect of light weight, small thickness and low construction energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

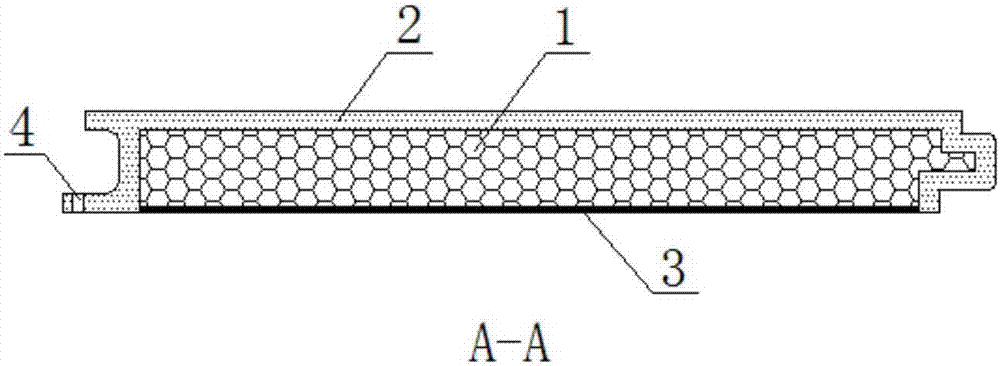

[0043] The thermal insulation decorative wallboard, such as Figure 1~4 As shown, a 25mm-thick high-efficiency thermal insulation material 1 with a thermal conductivity of 0.023W / (m K) and a combustion performance level of B1 is used as the insulation layer, and it is embedded in the U-shaped groove of the extruded wood-plastic special-shaped panel 2 The surface of the wood-plastic special-shaped panel 2 can be decorated with patterns, and the outer side of the back insulation layer is pasted with an ultra-thin heat insulation film 3 aluminum foil. The three are organically combined to form a thermal insulation and decorative composite wallboard. The vertical side of the wood-plastic special-shaped panel 2 is provided with convex and concave grooves, the vertical side is partially provided with a vertical side hole 4 with a diameter of 8mm, and the horizontal side of the wood-plastic special-shaped panel 2 is partially provided with a horizontal side hole with a diameter of 15m...

Embodiment 2

[0046] The thermal insulation decorative wallboard, such as Figure 1~4 As shown, the 30mm-thick high-efficiency thermal insulation material 1 phenolic resin foam with a thermal conductivity of 0.030W / (m K) and a combustion performance level of B1 is used as the thermal insulation layer, and embedded in the U-shaped groove of the extruded cement fiber special-shaped panel 2 , the surface of the cement fiber special-shaped panel 2 is painted with paint for decoration, and the outer side of the back insulation layer is pasted with an ultra-thin heat insulation film 3 aluminum foil, and the three are organically combined to form a thermal insulation and decorative composite wallboard. The vertical side of the cement fiber special-shaped panel 2 is provided with convex and concave grooves, the vertical side is partially provided with a vertical side hole 4 with a diameter of 8mm, and the horizontal side of the cement fiber special-shaped panel 2 is partially provided with a horizon...

Embodiment 3

[0049] The thermal insulation decorative wallboard, such as Figure 1~4 As shown, the high-efficiency thermal insulation material 1 airgel thermal insulation felt with a thickness of 20mm, a thermal conductivity of 0.02W / (m K), and a combustion performance grade of A is used as the thermal insulation layer, embedded in the U of the extruded wood-plastic special-shaped panel 2 In the shaped groove, the wood-plastic special-shaped panel 2 is treated with matt paint on the surface for decoration, and the outer side of the back insulation layer is pasted with ultra-thin heat insulation film 3 composite aluminum foil, and the three are organically combined to form a thermal insulation and decorative composite wallboard. The vertical side of the wood-plastic special-shaped panel 2 is provided with convex and concave grooves, the vertical side is partially provided with a vertical side hole 4 with a diameter of 8mm, and the horizontal side of the wood-plastic special-shaped panel 2 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com