Water-soluble polymer and application thereof

A water-soluble polymer and monomer polymerization technology, applied in the field of polymers, can solve the problems of excessive time loss, serious concrete retardation, bleeding, and segregation, and achieve good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

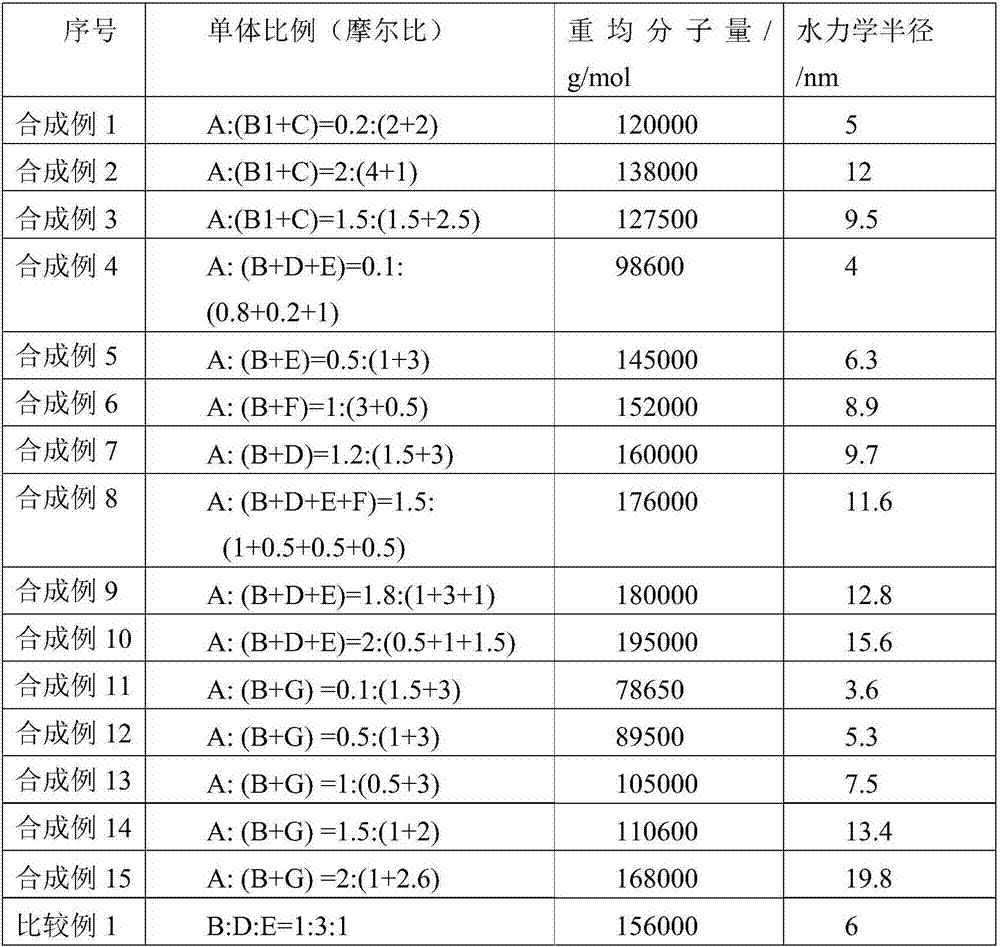

Synthetic example 1

[0061] 30kg tetrahydrofuran, 60kg methallyl polyoxyethylene ether (molecular weight is about 2400), 5.52kg methacryloylpropyltrimethylammonium chloride, 1.08kg 2-(perfluorohexyl) ethyl methacrylic acid Esters and 0.16kg of azobisisobutyronitrile were formulated as a mixed solution and added to the reaction kettle, heated and stirred until the temperature rose to 50°C, and kept for 4 hours. Then add 50 kg of 2% sodium hydroxide solution dropwise for 1 hour, keep warm for 1 hour and cool down to less than 45° C., add water to adjust the solid content to obtain a 20 percent polymer solution.

Synthetic example 2

[0063] 12kg of methoxy polyethylene glycol acrylate (molecular weight is about 1200), isopentenyl polyoxyethylene ether (molecular weight is about 4000), and 70kg of deionized water are made into a primer and added to the reaction kettle, heated and stirred to the temperature Rise to 80°C; add 0.35kg sodium persulfate, 2.6kg (3-acrylamidopropyl) trimethyl ammonium chloride, 1.6kg 2-(perfluorobutyl) ethyl acrylate and 7.8kg 2-perfluorooctyl Ethyl acrylate is formulated into a mixed solution, which is added dropwise to the base material, and the dropwise addition is completed in 3 hours and kept for 2 hours. Afterwards, 30 kg of 2% sodium hydroxide solution was added dropwise and kept for 1 hour, the temperature was lowered to less than 45° C., and water was added to adjust the solid content to obtain a 20% polymer solution.

Synthetic example 3

[0065] With 6.25kg allyl polyoxyethylene ether (molecular weight is 500), 60kg methallyl polyoxyethylene ether (molecular weight is 2400), 70kgN-methyl pyrrolidone, 8.28kg methacryloyl propyl trimethyl chloride Ammonium chloride, 5.17kg (3-acrylamidopropyl) trimethylammonium chloride, 2.62kg 1H, 1H, 2H, 2H-perfluorooctyl alcohol acrylate, 2.5kg ethyl acrylate, 0.65kg styrene to form a mixture Add the solution into the reaction kettle, heat and stir until the temperature rises to 60° C.; add 0.40 kg of azobisisobutyronitrile dropwise to the bottom material, and the dropwise addition is completed within 3 hours. Then add 60 kg of 2% sodium hydroxide solution dropwise for 1 hour, keep warm for 1 hour, cool down to less than 45°C, add water to adjust the solid content to obtain a 20% polymer solution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com