Precision coating device and coating method for special optical fiber impregnating compounds

A coating device and technology of special optical fiber, which is applied in the field of optical fiber processing, can solve the problems of poor coating effect and inability of coating mechanism to achieve uniform coating, etc., and achieve the effect of good compactness, convenient winding of tow, and not easy to fall off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

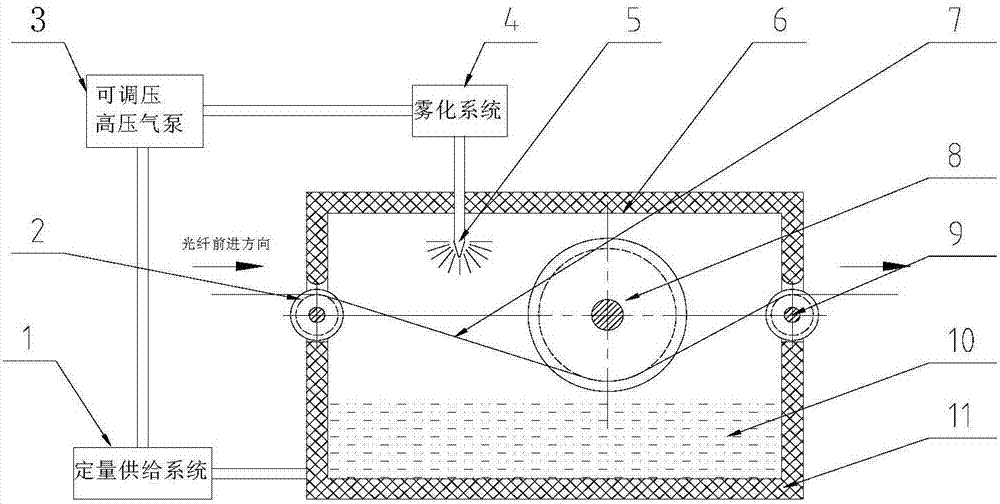

[0034] Such as figure 1 , 2 As shown, a precise coating device for a special optical fiber sizing agent, including a liquid circulation system and a coating homogenization mechanism, wherein the liquid circulation system includes a micro-quantity given supply system 1, an adjustable pressure high-pressure air pump 3 and an atomization system 4 .

[0035] The coating homogenization mechanism includes an inlet guide wheel 2, a homogenization wheel 8, an outlet guide wheel 9, a storage bottom box 11 and a sealing cover 6, and the inlet guide wheel 2, the homogenization wheel 8, and the outlet guide wheel 9 are all arranged on the storage In the bottom box 11, the sealing cover 6 is located directly above the storage bottom box 11, and is arranged in cooperation with the storage bottom box; the opposite side walls of the storage bottom box are provided with through holes for the passage of optical fibers, and the optical fiber bundle 7 passes through a through hole. After the ho...

Embodiment 2

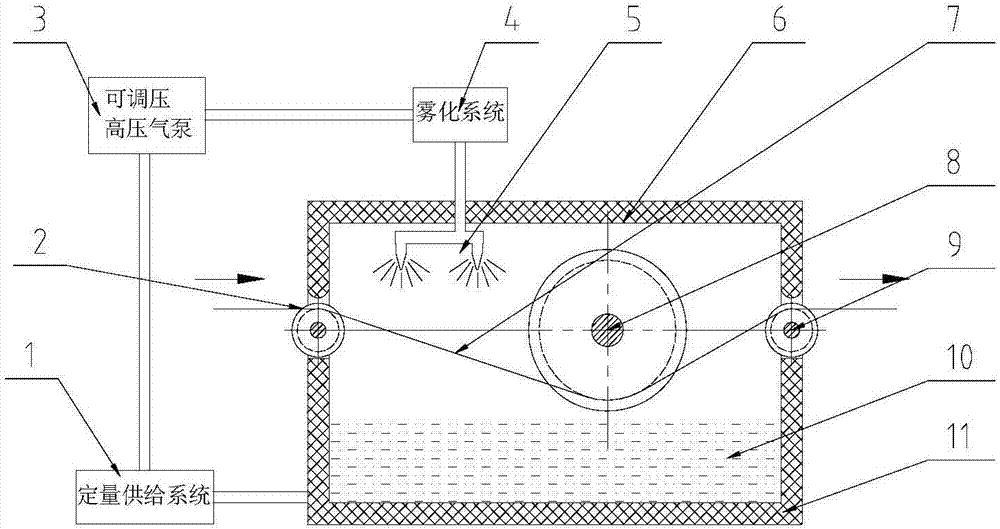

[0048] In this example, if image 3 As shown, the outlet of the atomization system 4 is connected with two atomization nozzles 5, the distance between two adjacent atomization nozzles is 100mm, the horizontal distance between the inlet guide wheel and the homogenization wheel is 500mm, and the distance between the lower end of the atomization nozzle and the optical fiber The height of the beam is 80mm. The cross section of the groove on the outer peripheral surface of the homogenizing wheel along the radial direction of the homogenizing wheel is arc-shaped.

[0049] Other parts are the same as in Embodiment 1.

Embodiment 3

[0051] The method for coating using the coating device described in embodiment one or two, may further comprise the steps:

[0052] Step 1. Inject the optical fiber sizing agent into the storage bottom box. The upper liquid level of the sizing agent is lower than the lower edge of the guide wheel, homogenizing wheel, and exit guide wheel;

[0053] Step 2. Pass one end of the optical fiber to be coated through a through hole on the side wall of the storage bottom box and enter the storage bottom box, bypass the inlet guide wheel, homogenizing wheel, and outlet guide wheel in turn, and pass through the through hole on the other side. Through the hole, and then connected with the external winding mechanism;

[0054] Step 3: Turn on the trace supply system, adjustable pressure high-pressure air pump and atomization system, then the infiltrant enters the trace supply system through the first pipeline in turn, then enters the adjustable pressure high-pressure air pump through the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com