Air flotation sewage treatment device

A treatment device and air flotation technology, applied in water/sewage multi-stage treatment, flotation water/sewage treatment, water/sludge/sewage treatment, etc., can solve high operating costs and large loss of electrolysis energy consumption electrode plates and other issues, to achieve the effect of low operating cost, low energy consumption, and sufficient and effective sewage treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

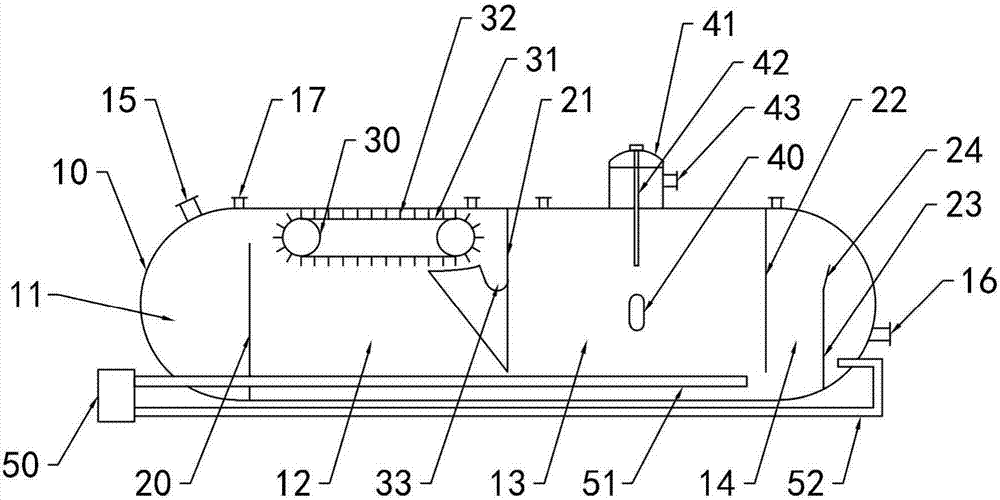

[0018] Such as figure 1 As shown, a sewage air flotation treatment device includes a cylinder 10, a dissolved air flotation device and an ultrasonic generator 40; the cylinder 10 includes a sewage chamber 11, an air flotation treatment chamber 12, an ultrasonic Demulsification chamber 13 and clear water overflow chamber 14; the top of the sewage chamber 11 is provided with a sewage water inlet 15, and a first partition perpendicular to the bottom of the cylinder body 10 is provided between the sewage chamber 11 and the air flotation treatment chamber 12 20. There is a gap between the top of the first partition 20 and the inner wall of the top of the cylinder body 10; the top of the air flotation treatment chamber 12 is provided with a slag scraping mechanism, and the slag scraping mechanism includes a sprocket 30, a chain 31 and the scraper 32 vertically arranged on the chain 31, the second partition 21 perpendicular to the bottom of the cylinder 10 is arranged between the air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com