Finger-joint plate bonding device

A finger-joint board and bonding technology, which is applied in the field of finger-joint board bonding devices, can solve the problems of lack of finger-joint boards and the inability to increase the thickness of the board, and achieve the effect of high automation and increased length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with embodiment.

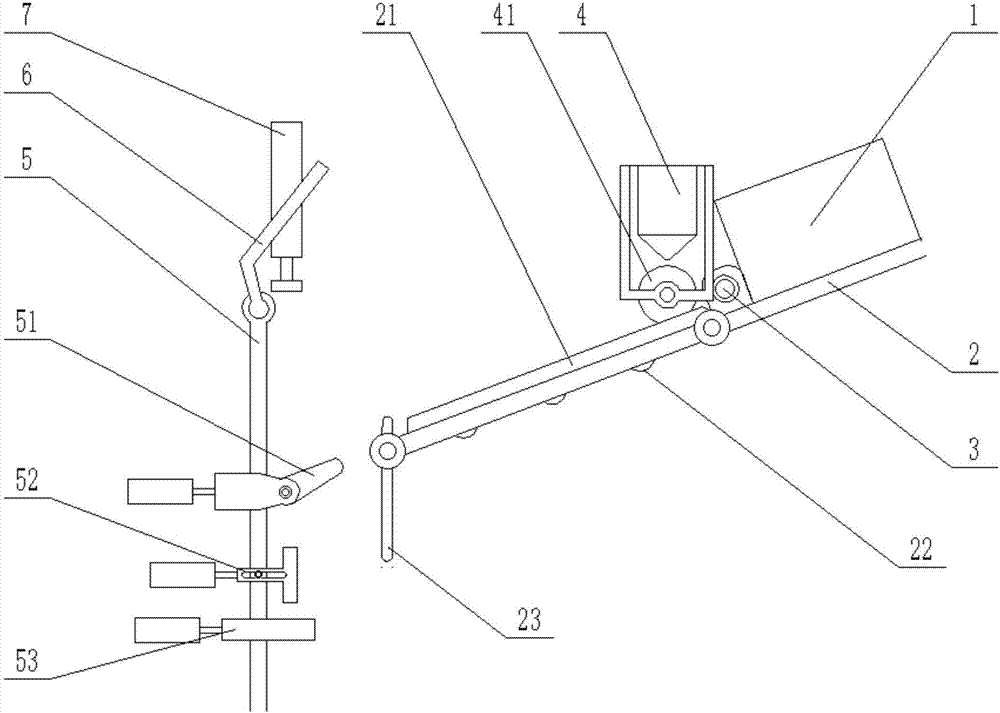

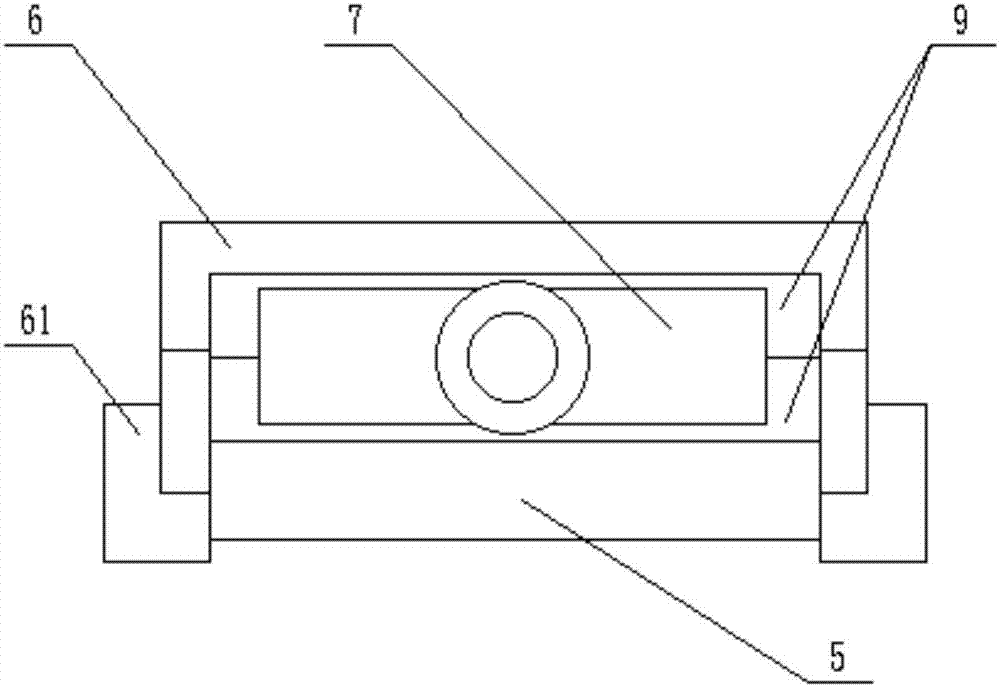

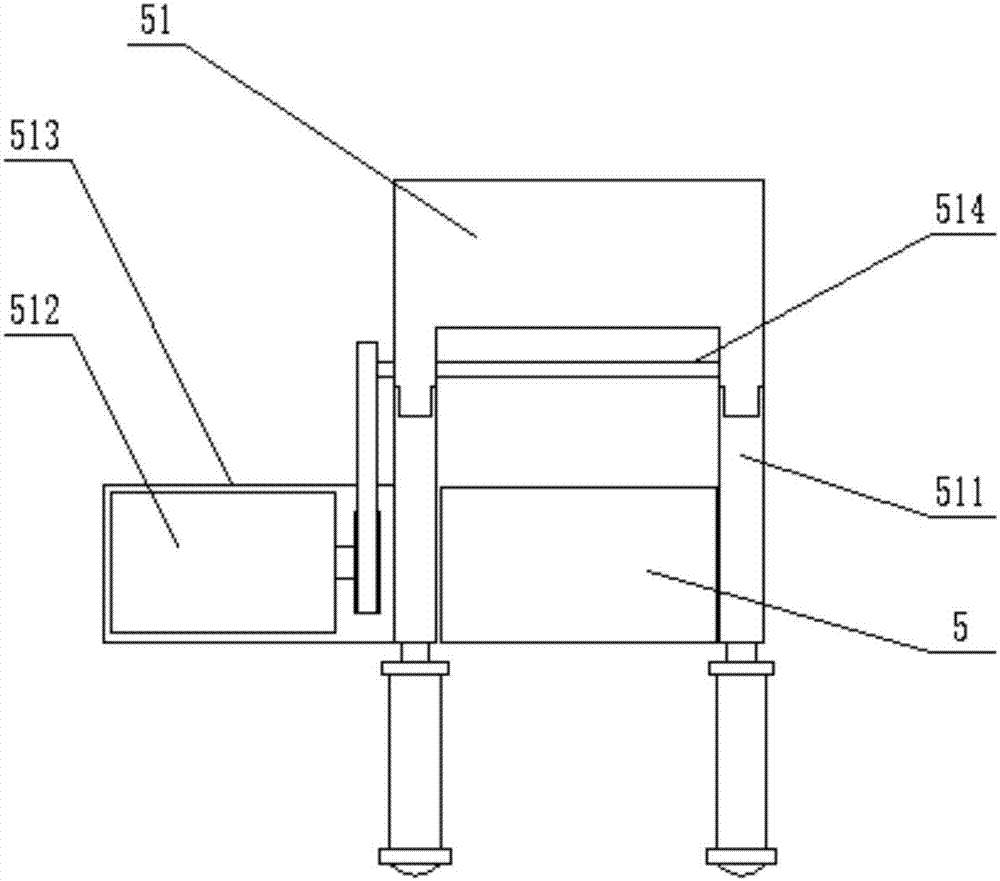

[0026] see figure 1 , Image 6 , in a preferred embodiment of the present invention, a finger-jointed board bonding device includes a transfer board 2 with an inclined board surface, and the board surface of the transfer board 2 is sequentially provided with a finger-joined board frame 1, Feeding motor 3 and gluing device 4. The finger-joint board rack 1 is used to hold finger-joint boards with the same specifications, and can be controlled by a PLC controller so that the finger-joint board rack 1 can successively put down several finger-joint boards onto the conveying board 2 . The output shaft of the feeding motor 3 is provided with rubber rollers, which have a certain pressure on the plate surface of the finger-joint plate, and the rubber rollers rotate and send the finger-joint plate out by friction. The gluing device 4 is fixedly arranged on the outside top of the conveying p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com