Nuclear power station double-web beam correcting tool and correcting method thereof

A technology of double webs and nuclear power plants, which is applied in the direction of beams, forming tools, manufacturing tools, etc., can solve the problems of double webs being easily deformed, difficult to correct, unable to pass thermal correction and mechanical correction, etc., and achieve simple operation principle and tooling structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

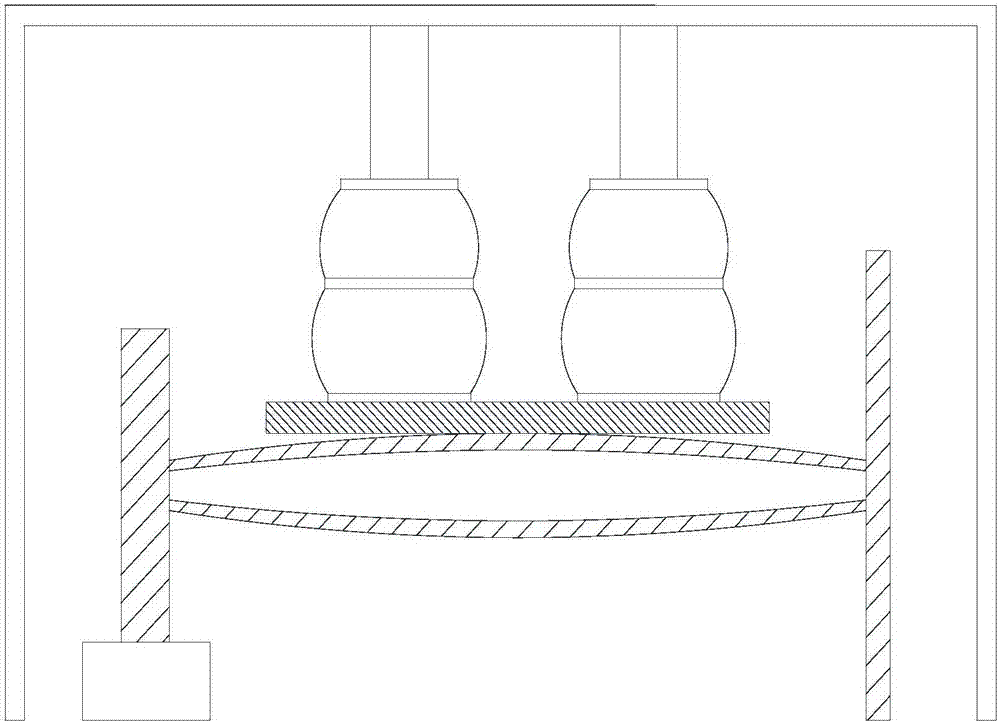

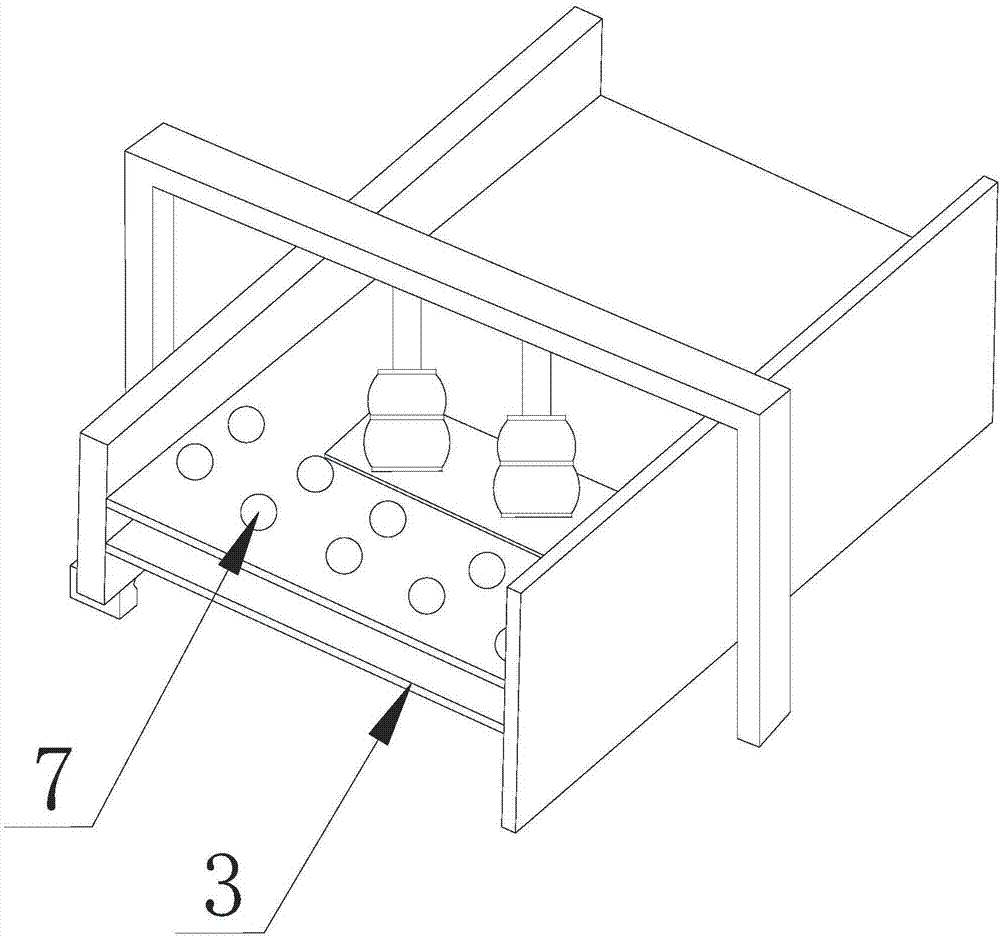

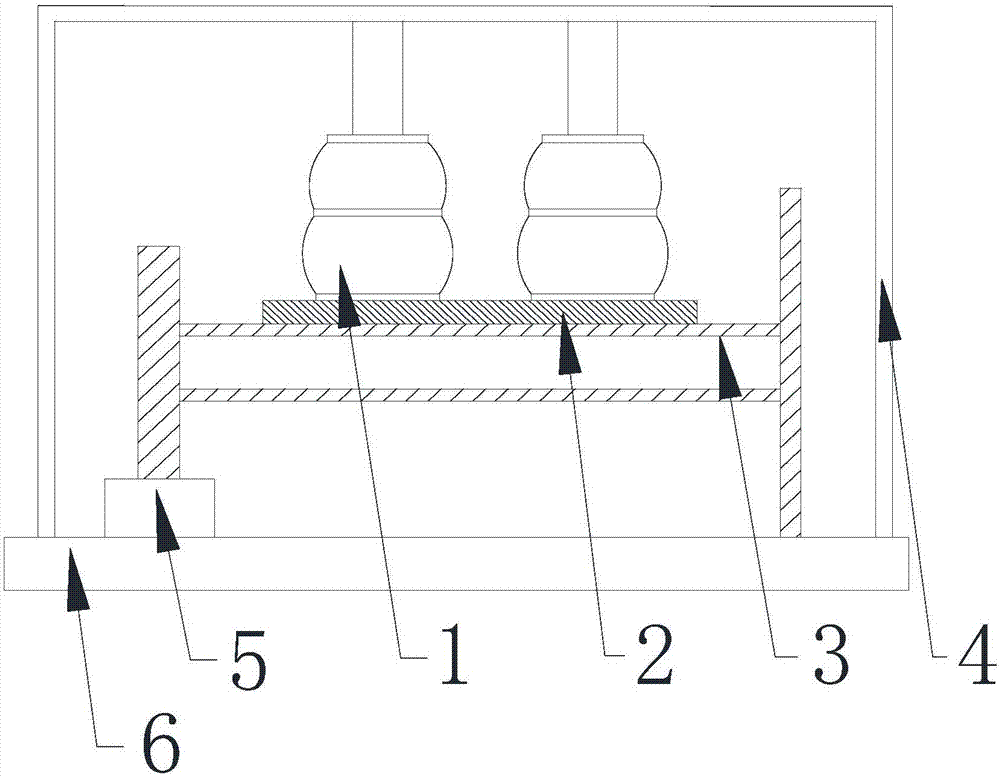

[0025] Such as Figure 1 to Figure 3 As shown, a double web girder correction tool for a nuclear power plant, its hardware structure is: at least two parallel and inverted U-shaped mounting frames 4 are used, and the opening ends of the mounting frames 4 are fixed on the working platform 6 , two jacks 1 are set in the inner cavity of each mounting frame 4 as a pressing device, and the tops of the jacks 1 are fixed to the top surface of the inner cavity of the mounting frame 4, and the jacks 1 are located above the working platform 6, and are The action of the jack 1 is formed to move in the direction of the vertical line, and a flame heating device 7 is also arranged on the working platform 6, and the heating place of the flame heating device 7 is located at the web of the part 3 to be processed. In order to increase the contact area, the The bottom of the mounting bracket 4 is provided with a briquetting block 2, and the briquetting block 2 is arranged on the web of the part ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com