Stainless steel cold-rolled plate continuous production system and method

A production system, stainless steel technology, applied in the direction of metal rolling, etc., can solve the problem of low stainless steel production, achieve the effect of saving construction land, saving engineering investment, and improving the yield of finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] specific implementation plan

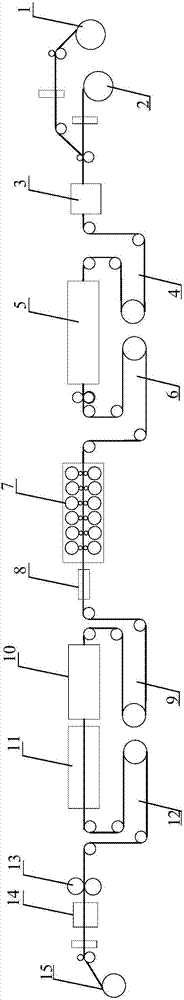

[0023] Attached below figure 1 , to further describe the continuous production system and method of stainless steel cold-rolled plate of the present invention.

[0024] in such as figure 1 The shown continuous production system for stainless steel cold-rolled plates includes a first uncoiler 1, a second uncoiler 2, a welding machine 3, a hot zone pickling inlet looper 4, a black coil pickling section 5, a rolling mill inlet looper 6, Continuous rolling mill 7, cleaning section 8, rolling mill exit looper 9, cold plate annealing furnace 10, cold strip pickling section 11, cold strip pickling exit looper 12, temper mill 13, tension leveling and inspection looper area 14, Coiler 15.

[0025] The first uncoiler 1 and the second uncoiler 2 have the ability to uncoil the steel strip with a thickness of 1mm~8mm. The welding of the strip head and strip tail is completed at the welding machine 3. The laser welding machine has good weld quality a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com