Wine bottle liquid level detection system and method suitable for wine foam left in bottle bodies

A liquid level detection and wine bottle technology, applied in sorting and other directions, can solve problems such as inaccurate detection results and achieve accurate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

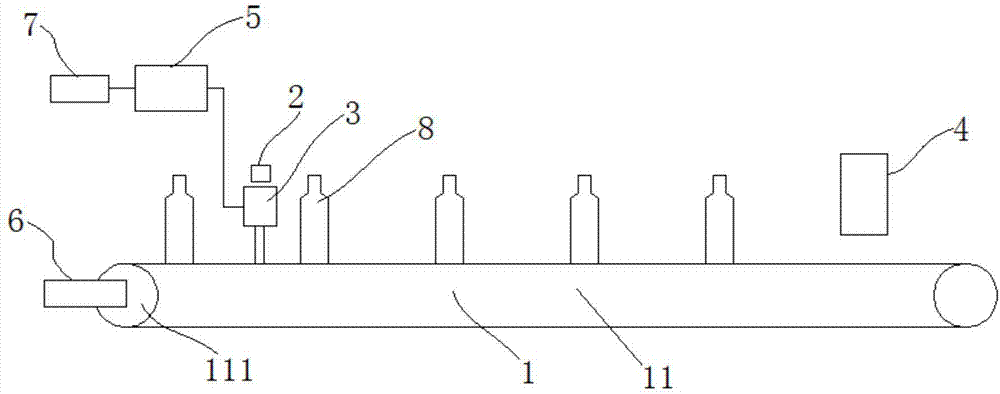

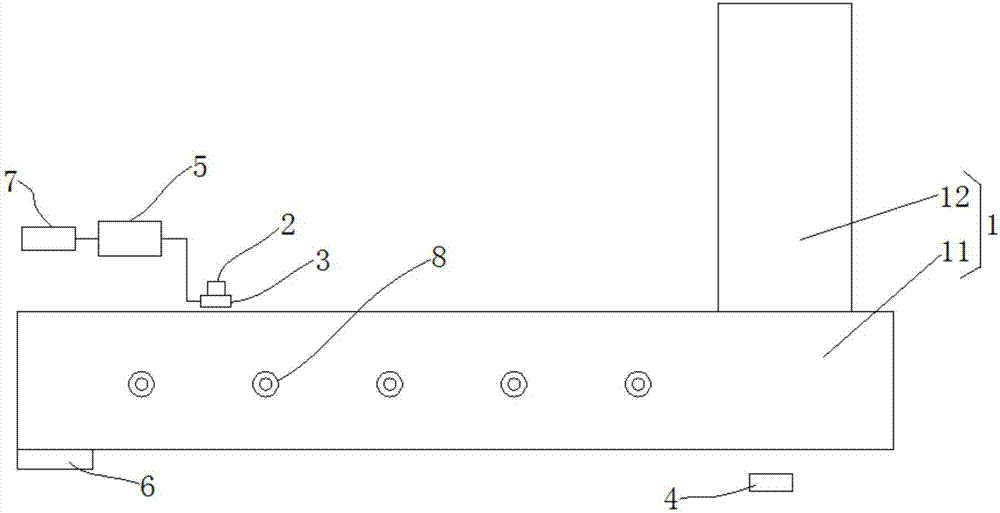

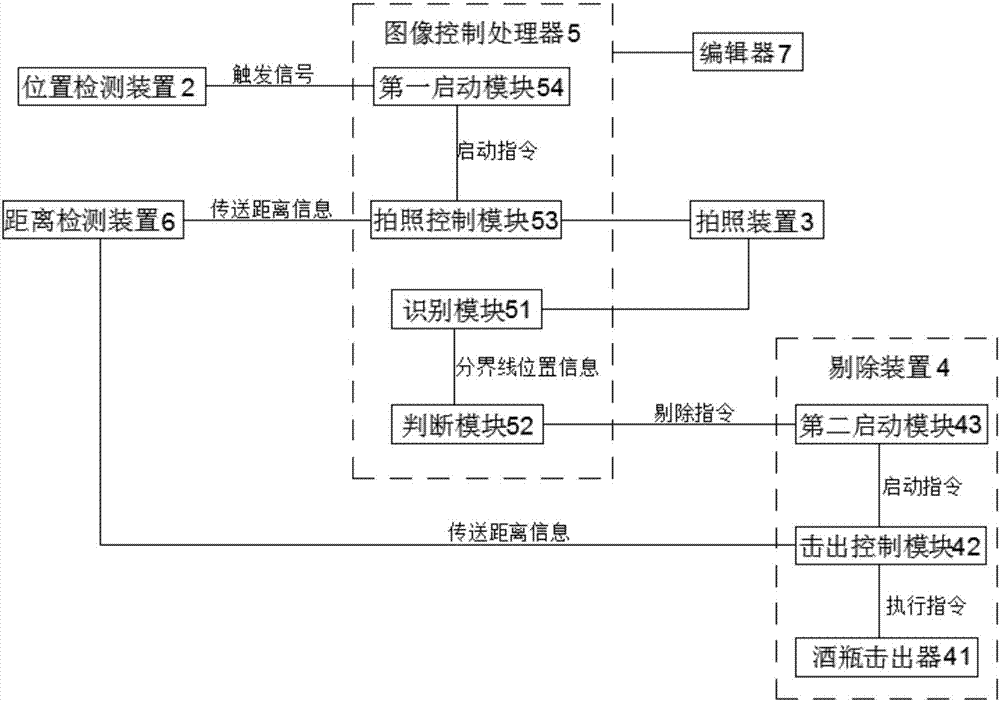

[0045] Such as Figure 1 ~ Figure 3 As shown, a wine bottle 8 liquid level detection system suitable for wine foam remaining in the bottle according to the present invention includes a transmission device 1 , a position detection device 2 , a photographing device 3 , a rejecting device 4 and an image control processor 5 . The transmission device 1 can sequentially transmit the wine bottle 8 to the position detection device 2, the photographing device 3 and the rejecting device 4. When the position detection device 2 detects that a wine bottle 8 passes by, a trigger signal is sent, and the image control processor 5 receives the trigger signal and Send photographing i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com