Vacuum cooling machine capable of solving food safety hygienic problems

A vacuum cooler and food safety technology, applied in food preservation, food science, household refrigeration equipment, etc., can solve problems that threaten food safety, affect the normal operation of the box, and affect food safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0124] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0125] The purpose of the present invention is to solve the food safety and sanitation problem. The whole can reach the highest cleaning and waterproof level, the waterproof level can reach IP68 level, and the steam cleaning protection level can reach IP69K level, so as to reduce the bacterial breeding points on food machinery and equipment, and achieve the colony stock minimize.

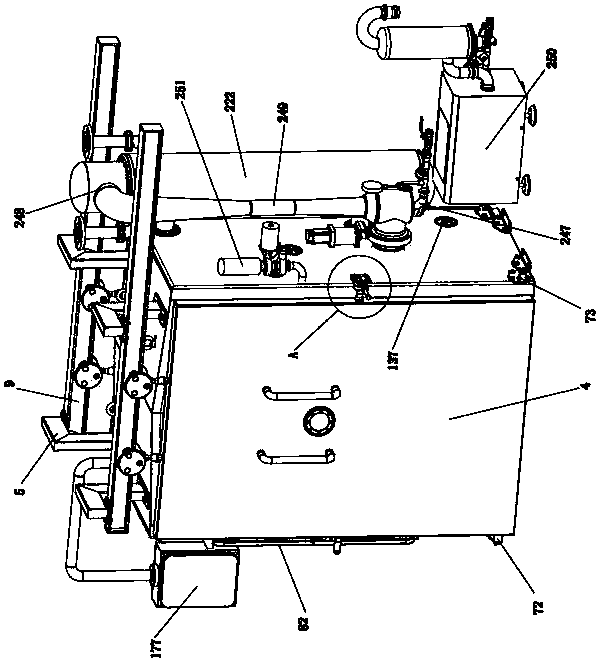

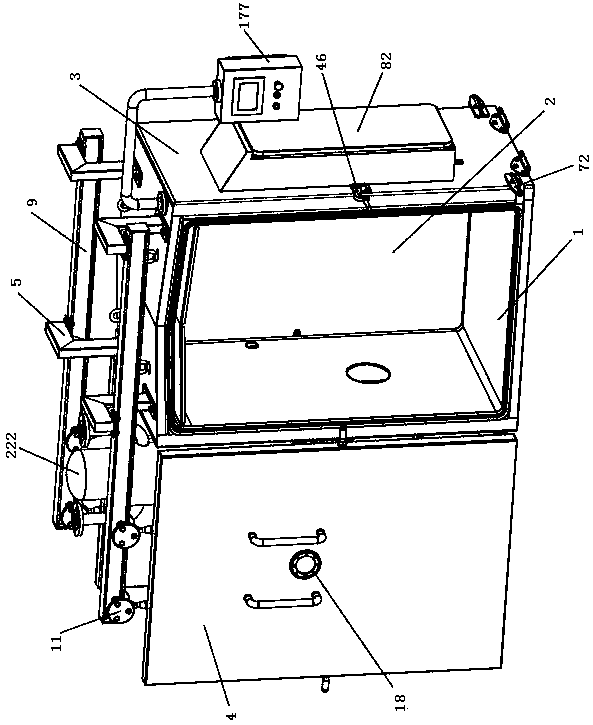

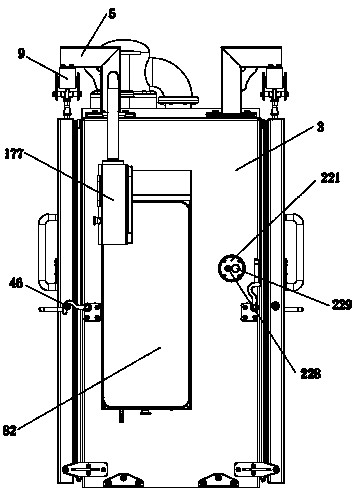

[0126] Such as figure 1 , 2 , 3, 4, 57, 58, 59, 60, and 61, a vacuum cooler capable of solving food safety and hygiene problems, including a box body 3 with inlet and outlet ports 1 and 2, for sealing the inlet and outlet ports 1 , 2, the airtight door 4, and the airtight door 4 are respectively hung on the inlet and outlet ports 1 and 2 of the box body 3 and can slide left and right along the box body 3. Specifically, L-shaped doors are respectively provided above...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com