Avenanthramide extract as well as extraction method and application thereof

A technology of oat anthramid and extraction method, which is applied in the application field of oat anthramid extract and oat anthramid extract, and can solve the problems of underestimating purity, emphasizing yield, and unseen oat anthramid solvent selection and condition optimization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

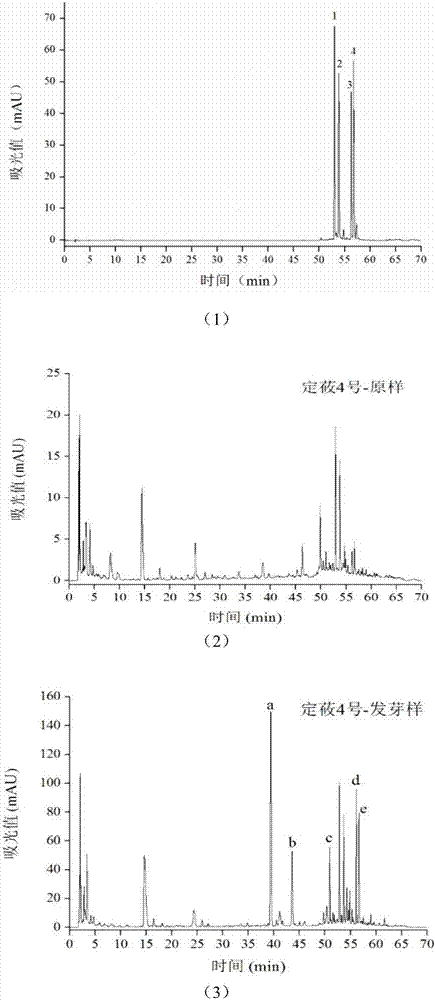

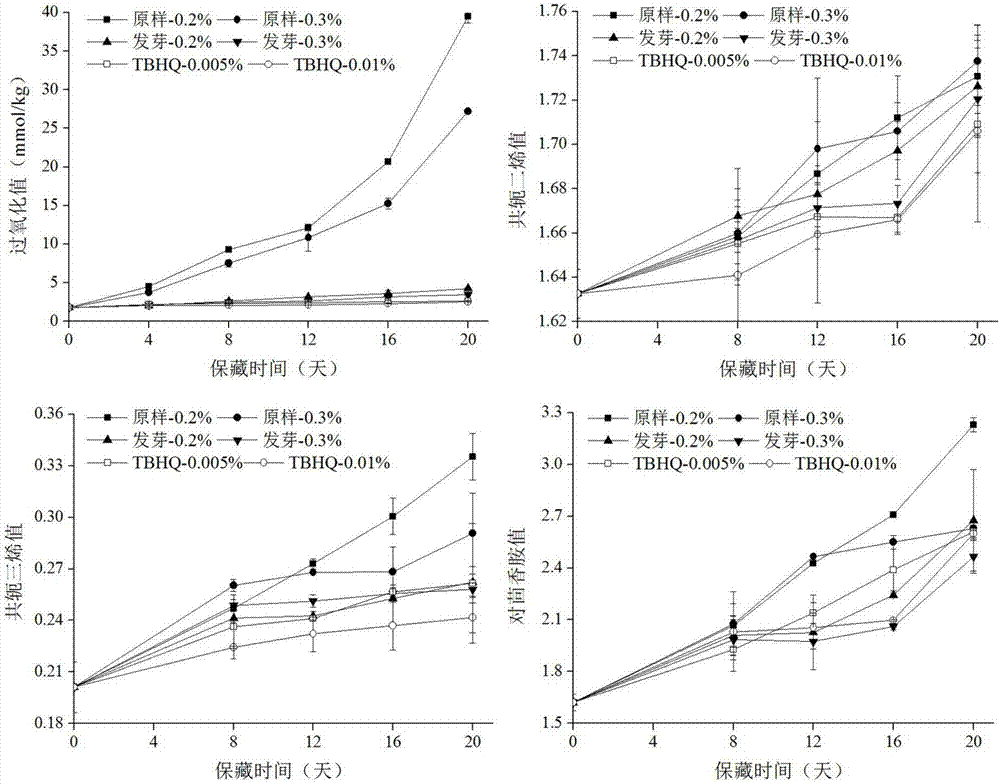

[0094] Embodiment 1: extract oat anthramid

[0095] The implementation steps of this embodiment are as follows:

[0096] A. Oat pretreatment

[0097] Oats are disinfected with 30g / L sodium hypochlorite disinfectant aqueous solution for 10min, washed with water, then soaked in cinnamic acid aqueous solution with a concentration of 0.02% by weight at a temperature of 4°C for 24h, and drained;

[0098] B. Sprouted oats

[0099] Step A The oats drained of water were germinated in a germination tray in an incubator at 12°C and protected from light for 7 days, and sprayed with a concentration of 0.02% cinnamic acid aqueous solution by weight every 6h during the germination process , to obtain sprouted oats;

[0100] C. Sprouted Oat Treatment

[0101] Using an electric blast drying oven, dry the germinated oats obtained in step B until the moisture content is 10% by weight, and then use a swinging high-speed pulverizer to pulverize it into germinated oat flour with a particle siz...

Embodiment 2

[0107] Embodiment 2: extract oat anthramid

[0108] The implementation steps of this embodiment are as follows:

[0109] A. Oat pretreatment

[0110] Oats were disinfected with 5g / L sodium hypochlorite disinfectant aqueous solution for 30min, washed with water, then soaked at a temperature of 12°C for 20h in a cinnamic acid aqueous solution with a concentration of 0.2% by weight, and drained;

[0111] B. Sprouted oats

[0112] Step A The oats drained of water were germinated in a germination tray in an incubator at a temperature of 14°C and protected from light for 6 days, and sprayed with 0.2% cinnamic acid by weight every 18h during the germination process aqueous solution to obtain germinated oats;

[0113] C. Sprouted Oat Treatment

[0114] Dry the germinated oats obtained in step B to a moisture content of 4% by weight using an electric blast drying oven, then use a swing-type high-speed pulverizer to pulverize it into germinated oat flour with a particle size of 250 ...

Embodiment 3

[0120] Embodiment 3: extract oat anthramid

[0121] The implementation steps of this embodiment are as follows:

[0122] A. Oat pretreatment

[0123] The oats were disinfected with 20g / L sodium hypochlorite disinfectant aqueous solution for 20min, washed with water, then soaked at a temperature of 35°C for 8h in a cinnamic acid aqueous solution with a concentration of 1.2% by weight, and drained;

[0124] B. Sprouted oats

[0125]Step A The oats that have been drained of water are germinated in a germination tray in an incubator at a temperature of 16° C. and protected from light for 4 days. During the germination process, the concentration of 1.2% cinnamic acid by weight is sprayed every 10 hours. aqueous solution to obtain germinated oats;

[0126] C. Sprouted Oat Treatment

[0127] The germinated oats obtained in step B are dried to a moisture content of 11% by weight using an electric blast drying oven, and then crushed into germinated oat flour with a particle size of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| collision energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com