Uniform load surface curvature-based simply supported beam crack damage identification method

A technology of damage identification and surface curvature, applied in elastic testing, testing of machine/structural components, measuring devices, etc., can solve problems such as inability to quantitatively detect crack heights

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will be further described below in conjunction with the drawings and embodiments. When the following description refers to the drawings, unless otherwise indicated, the same numbers in different drawings represent the same or similar elements.

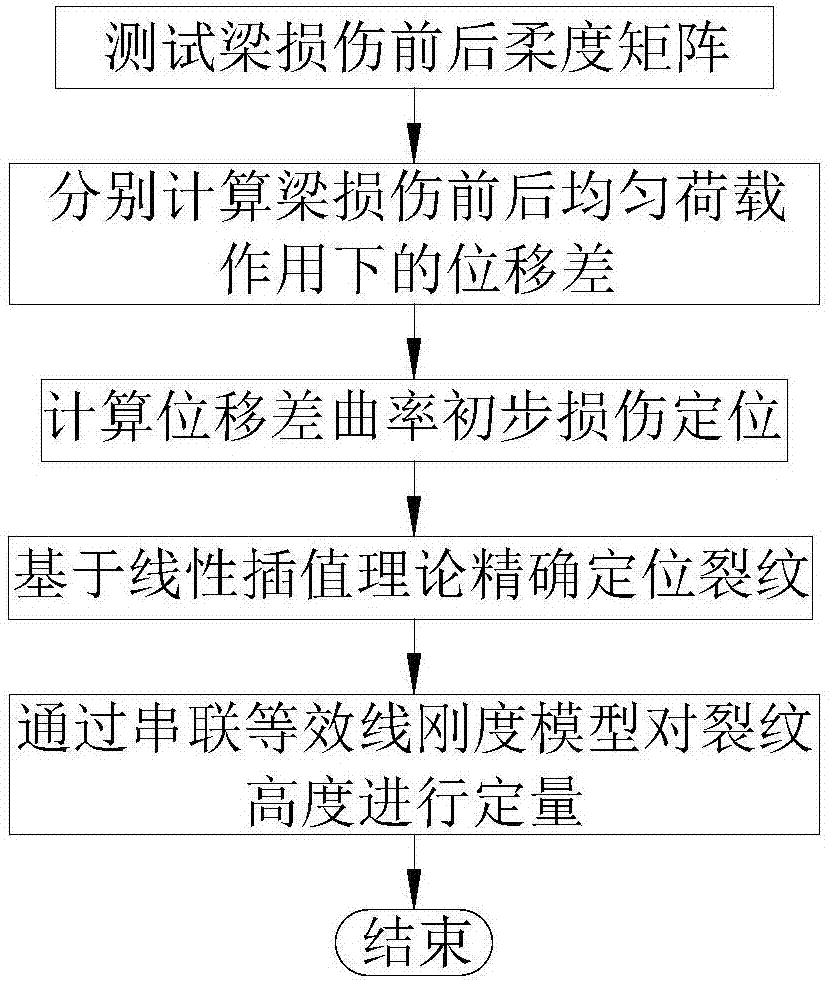

[0055] see figure 1 , is a flow chart of the simply supported beam crack damage identification method with uniform load surface curvature of the present invention, and its specific steps are as follows:

[0056] Step 1: Obtain the modal parameters of the simply supported beam before and after damage through testing, and calculate the modal flexibility matrix from the frequency and mode shape;

[0057] Step 2: Apply a uniform load to the simply supported beam, and multiply the uniform load by the difference in flexibility matrix before and after the structural damage to obtain the corresponding displacement difference;

[0058] Step 3: Calculate the curvature of the displacement difference to obtain the cur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com