A fast-suction and slow-discharge air valve with built-in maintenance filter

A kind of air valve, slow discharge technology, applied in the direction of dispersing particle filtration, valve absorbing fluid energy device, lift valve, etc., can solve the problems of pipeline and equipment damage, strong impact on pipeline, pipe burst accident, etc., to achieve reliable sealing , Enhance the effect of fast suction and slow discharge, long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

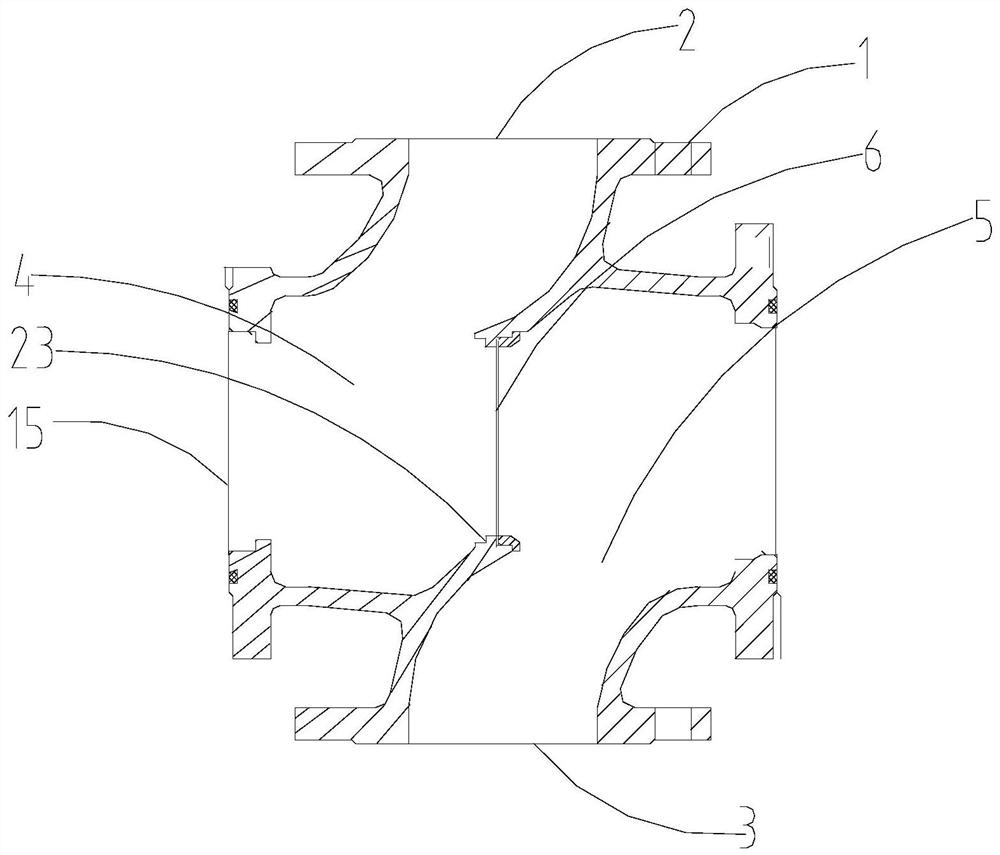

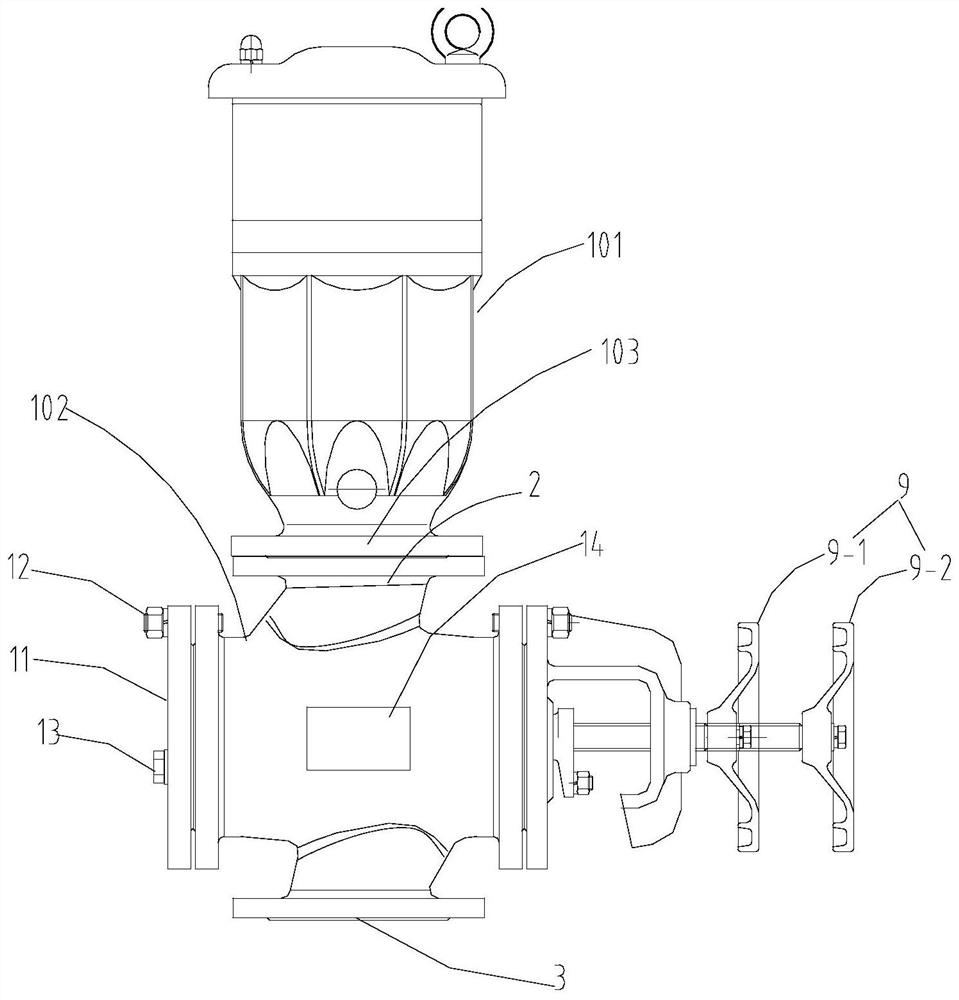

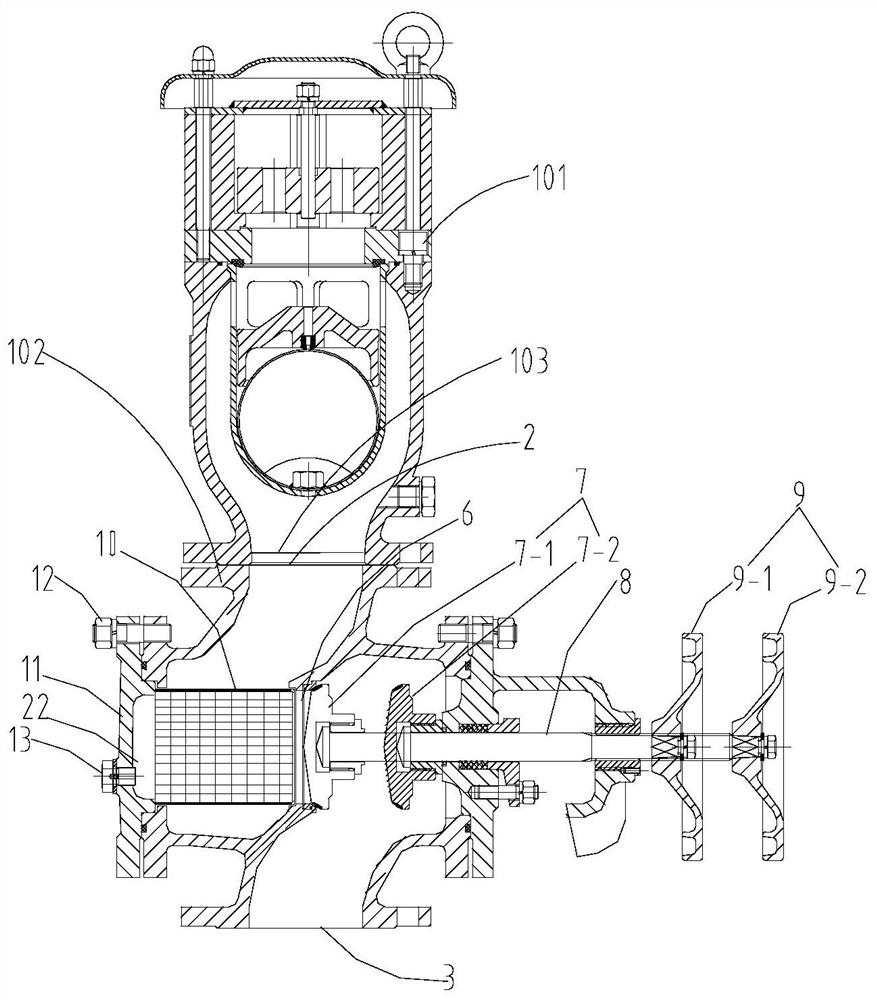

[0040] Such as Figure 1-9 As shown, the present embodiment provides a fast suction and slow discharge air valve with built-in maintenance filter, including an air valve body 101 and a valve assembly 102, the valve opening 103 of the air valve body 101 and the valve assembly 102 pass through a flange seal connection for easy maintenance and replacement. The main body 101 of the air valve in this embodiment uses an anti-hammer air valve for further illustration. Specifically, the patent number 201520384037.9 previously applied by our company is used. The patent name is an anti-hammer air valve. The specific structure and function will not To repeat them one by one, this embodiment mainly integrates the air valve and the valve assembly without changing the structure of the air valve, and has its own functions of maintenance, filtration and quick suction and slow discharge on the premise of having all the original functions of the air valve. , to avoid water hammer caused by sudd...

Embodiment 2

[0057] Such as Figure 10 As shown, this embodiment is basically the same as Embodiment 1, the difference is that the number of reinforcing ribs 21 is at least two, and the two reinforcing ribs 21 cross each other and are fixed on the port of the filter cartridge close to the valve cover in a cross shape. It can play the role of Embodiment 1, and can further strengthen the strength and stability of the filter cartridge with double-layer structure through a plurality of reinforcing ribs.

Embodiment 3

[0059] Such as Figure 11As shown, this embodiment is basically the same as Embodiment 1, the difference is that the air valve body 101 and the valve assembly 102 are integrated, and are integrated by casting, so that the seamless connection has a better sealing effect and avoids the leakage caused by the flange connection Point, the air valve main body 101 adopts an angle-shaped air valve, specifically the patent number 201520383478.7 applied by our company before, and the patent name is a waterproof hammer air valve, and the specific structure and function will not be repeated one by one.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com