Concrete backfill device of unbonded ring anchor prestress lining structure anchorage groove and construction method

An anchor groove and prestressing technology, which is applied in wellbore lining, tunnel lining, earthwork drilling and production, etc., can solve the problems of limited remaining space, oil leakage in anchor groove, large cracks, etc., and achieves easy popularization and application and adjustability Strong, high-precision process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

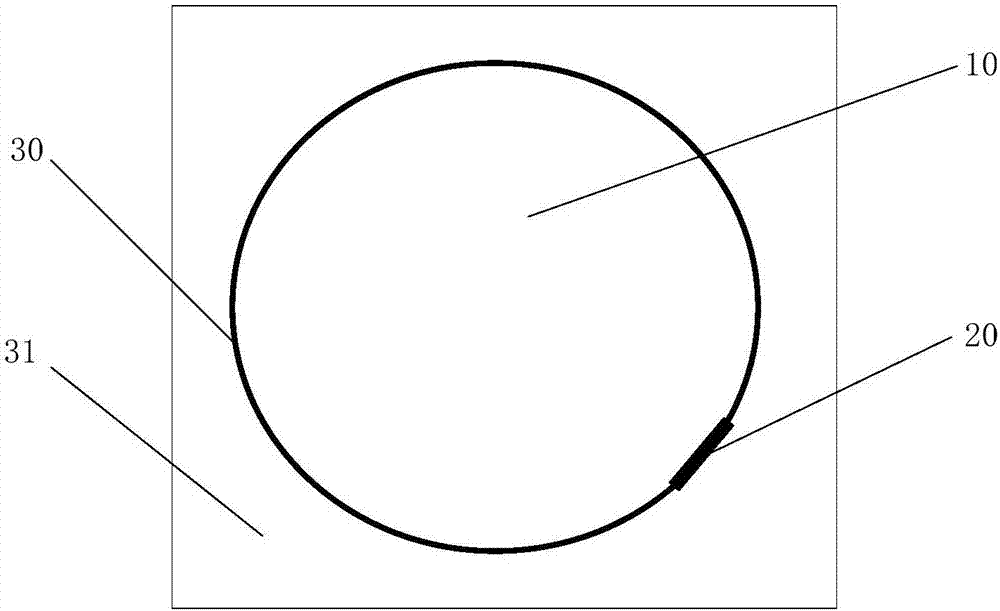

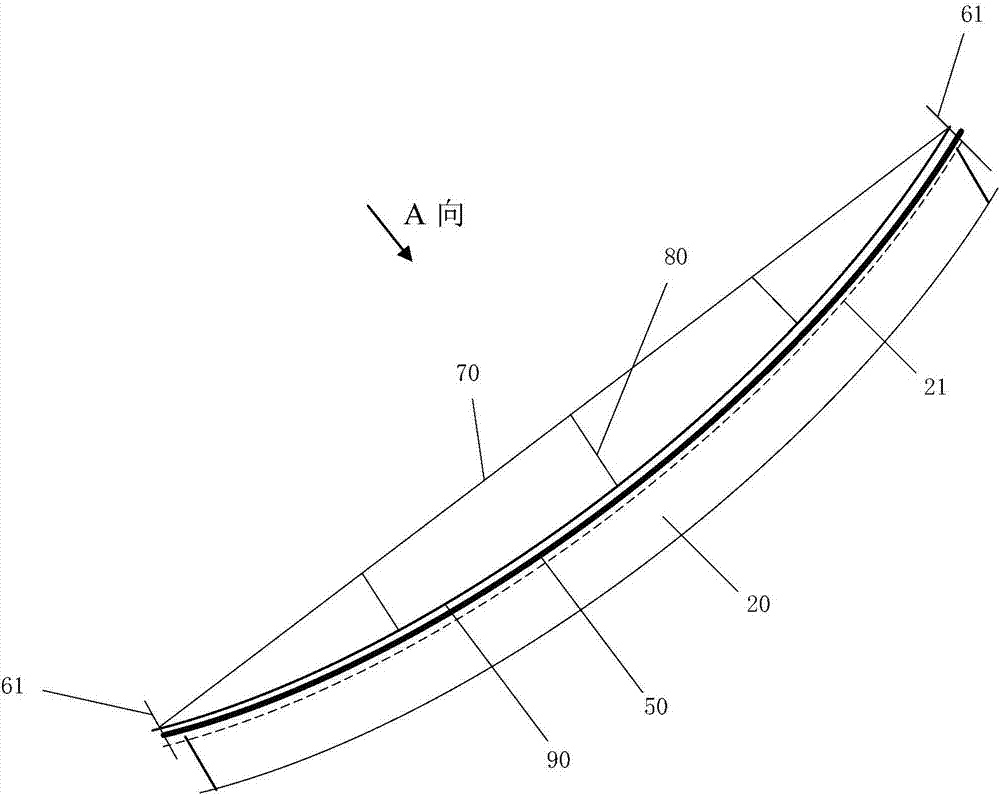

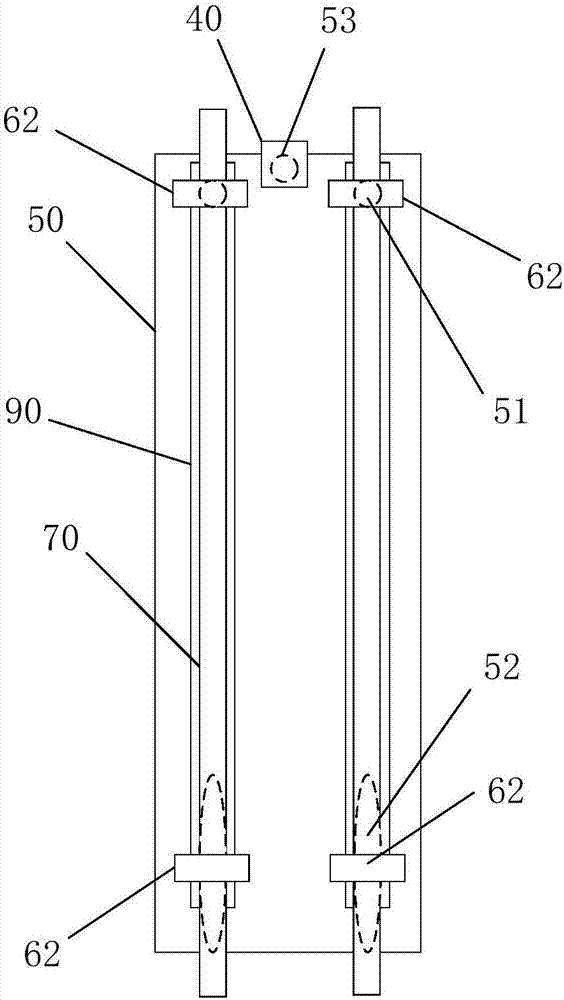

[0025] Such as Figure 1 to Figure 3 As shown, the concrete backfilling device for the anchor groove of the unbonded ring anchor prestressed lining structure of the present invention is used for backfilling the anchor groove 20 on the unbonded ring anchor prestressed lining structure 30 (lining structure for short). . The concrete backfilling device of the present invention includes a pouring formwork 50 and a curvature adjusting member, wherein: the pouring formwork 50 is a bendable flat plate for covering the notch 21 of the anchorage groove 20, and one end of the pouring formwork 50 is a fixed end and the other end It is the adjusting end; the fixed end of the pouring template 50 is provided with a circular fixing hole 51, and the adjusting end is provided with an oval adjusting hole 52, and the fixing hole 51 and the adjusting hole 52 are respectively used to pass through the two ends of the notch 21 of the anchor groove 20. On the embedded part 61; the curvature adjustme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com