Shuttle weft insertion apparatus with tracks

A technology of weft insertion device and track, which is applied in the direction of textile, textile, papermaking, loom, etc., can solve the problems of low production efficiency, manual shuttle picking, and abnormal weaving, etc., and achieve safe and fast production, ensure stability, and large weft storage capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

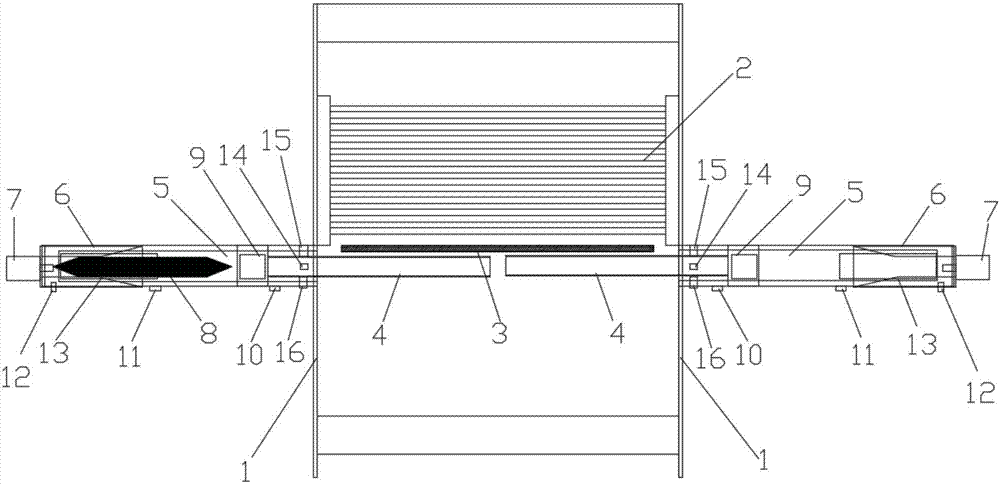

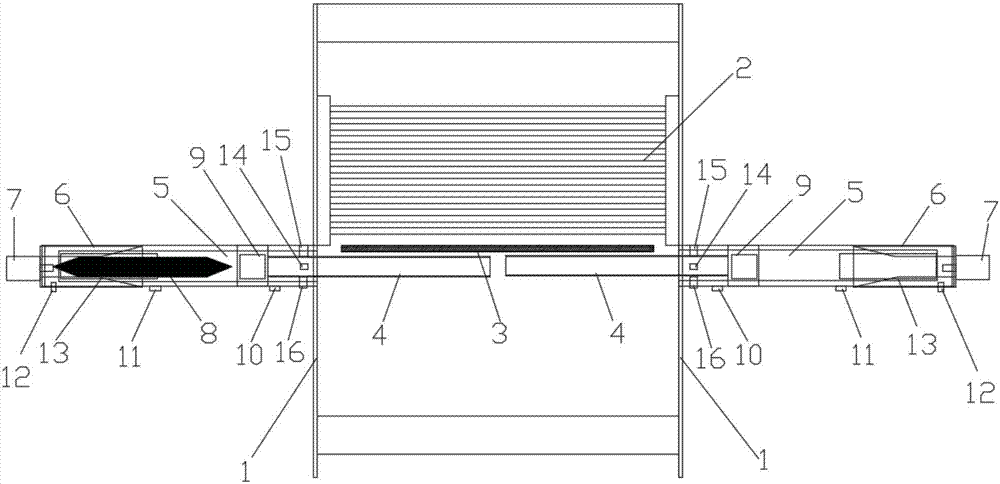

[0019] Such as figure 1 As shown, this embodiment provides a shuttle weft insertion device with rails, which includes a fixed bracket 1, a U-shaped guide rail 4, a heald frame 2, a steel reed 3, a linear guide 9, and a rail telescopic drive mechanism 5. Shuttle stop mechanism 6, shuttle mechanism 7, shuttle 8, U-shaped guide rail front dead center detection device 10, U-shaped guide rail rear dead center detection device 11, shuttle in-position detection device 12, shuttle box cover 13, U-shaped guide rail Under-track guide wheel bearing 14, U-shaped guide rail inner guide wheel bearing 15, U-shaped guide rail outer guide wheel bearing 16; the U-shaped guide rail 4 not only includes the front end rail into the shed, but also when the shuttle is stationary Shuttle box position; the bottom of the U-shaped guide rail 4 near the tail end and the sliding block of the linear guide 9 are fixed, and the lower U-shaped guide rail bearing 14 and the inner guide wheel of the U-shaped guide...

Embodiment 2

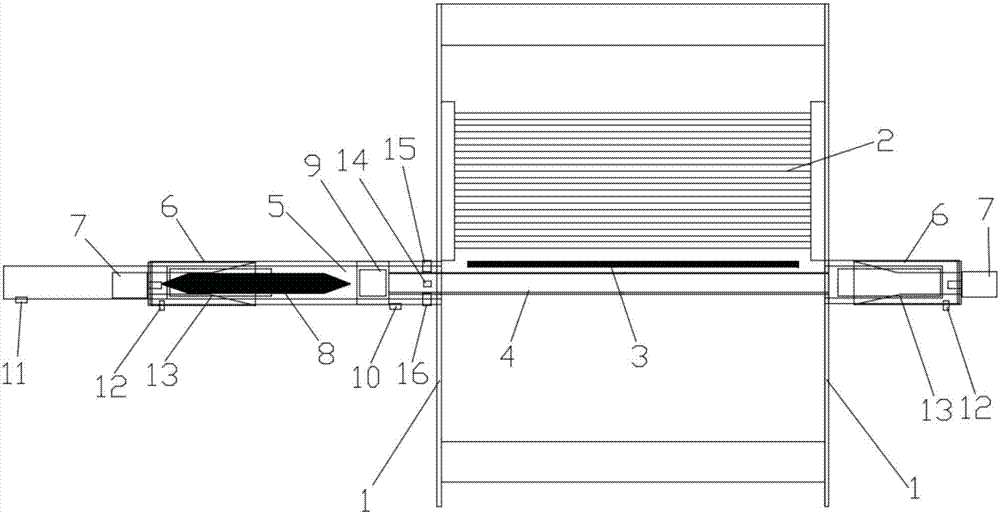

[0022] Such as figure 2 As shown, this embodiment provides a shuttle weft insertion device with rails, which includes a fixed bracket 1, a U-shaped guide rail 4, a heald frame 2, a steel reed 3, a linear guide 9, a rail telescopic structure 5, a stop Shuttle mechanism 6, shuttle mechanism 7, shuttle 8, U-shaped guide rail front dead center detection device 10, U-shaped guide rail rear dead center detection device 11, shuttle in-position detection device 12, shuttle box cover 13, U-shaped guide rail Lower guide wheel bearing 14, U-shaped guide rail inner guide wheel bearing 15, U-shaped guide rail outer guide wheel bearing 16; the U-shaped guide rail 4 is on one side of the loom, which includes the front end rail into the shed , It is the position of the shuttle box when the shuttle is stationary; the sliding block fixed under the U-shaped guide rail 4 described in the bracket 1 near the tail end and the linear guide 9 is fixed, and the lower U-shaped guide rail is located near...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com