Graphene-containing HNBR (hydrogenated butadiene-acrylonitrile rubber) nanocomposite and preparation method

A technology of hydrogenated nitrile rubber and nano-composite materials, which is applied in the field of rubber materials, can solve problems such as difficulty in meeting product quality requirements, poor graphene dispersion, and poor process stability, so as to enhance the ability to resist crack growth and improve dispersion. , Improve the effect of tear resistance and fatigue performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The preparation method of graphene / carbon nanotube paraffin oil described above, the steps of preparation are as follows:

[0026] 1. According to the mass fraction ratio of graphene and carbon nanotubes being 1:3 to 1:1, weigh graphene and carbon nanotubes to obtain a graphene / carbon nanotube mixture;

[0027] 2. Put the graphene / carbon nanotube mixture and paraffin oil in a container according to the ratio of parts by mass of 20:100 to 50:100, and then stir it with a high-speed rotary mixer at a temperature of 40°C to 60°C at a speed of 200rpm to 1000rpm , and stirred for 0.5h to 4h to obtain graphene / carbon nanotube paraffin oil.

[0028] A kind of preparation method of the hydrogenated nitrile butadiene rubber nanocomposite material containing graphene as described above, the steps of preparation are as follows:

[0029] 1. Ingredients: weigh various raw materials according to the formula;

[0030] 2. Mixing: Add raw hydrogenated nitrile rubber, zinc oxide, steari...

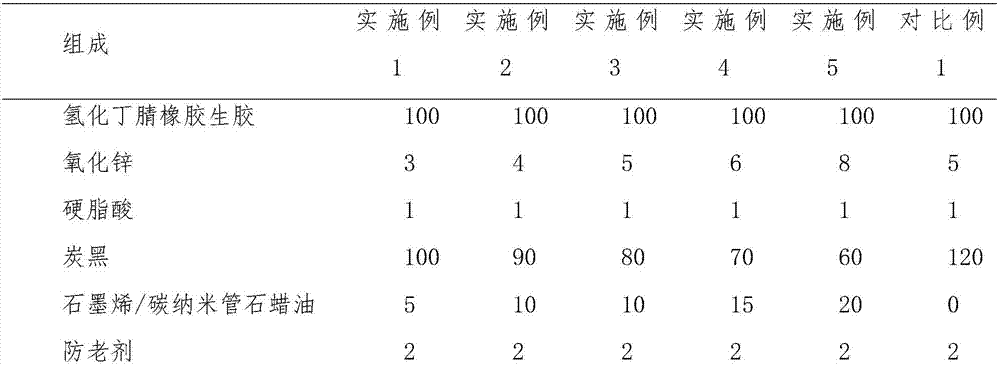

Embodiment 1~5 and comparative example 1

[0033] Table 1 is the ratio by mass and number of Examples 1 to 5 of the present invention and Comparative Example 1, wherein the figures in each formula are parts by weight, the ACN content in the hydrogenated nitrile rubber raw rubber used is 34wt%, and the mole of residual double bonds The content is 0.9%; the diameter of the graphene in the graphene / carbon nanotube paraffin oil used is 10 microns, the number of layers is 50 layers, the carbon nanotubes are multi-walled carbon nanotubes with a diameter of 40 nanometers, and the viscosity of the paraffin oil is 6000cps; In the preparation process of graphene / carbon nanotube paraffin oil, the mass fraction ratio of graphene and carbon nanotube is 1:3, and the mass fraction ratio of graphene / carbon nanotube mixture and paraffin oil is 50:100, At a temperature of 50° C., the rotation speed of the high-speed rotary mixer is 1000 rpm, and the stirring time is 0.5 h.

[0034] The preparation method of hydrogenated nitrile rubber a...

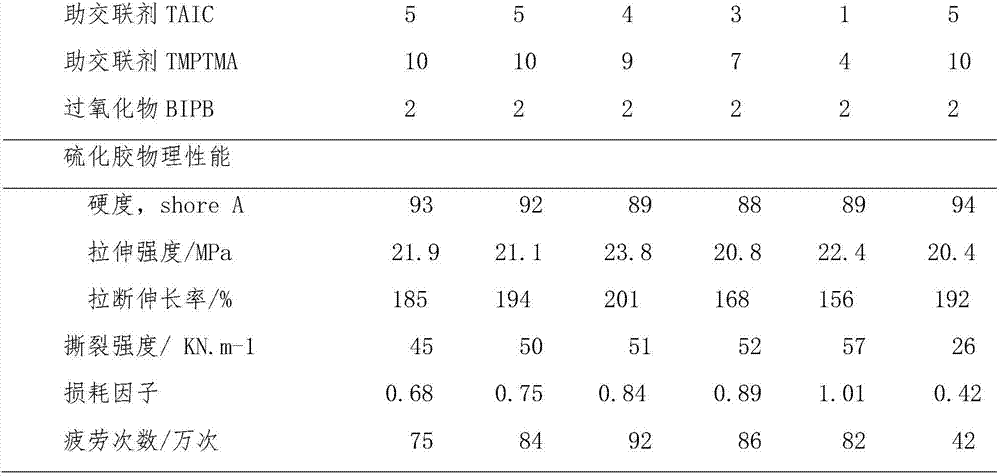

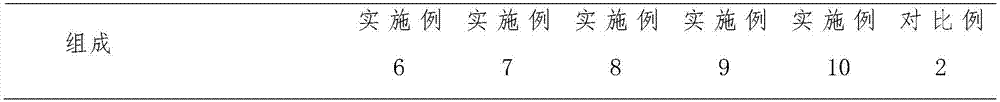

Embodiment 6~10 and comparative example 2

[0044] Table 2 is the ratio by mass and number of Examples 6 to 10 of the present invention and Comparative Example 2, wherein the figures in each formula are parts by weight, the ACN content in the raw hydrogenated nitrile rubber used is 39wt%, and the mole of residual double bonds The content is 0.9%; the diameter of the graphene in the graphene / carbon nanotube paraffin oil used is 5 microns, the number of layers is 10 layers, the carbon nanotubes are multi-walled carbon nanotubes with a diameter of 30 nanometers, and the viscosity of the paraffin oil is 8000cps; In the preparation process of graphene / carbon nanotube paraffin oil, the mass fraction ratio of graphene and carbon nanotube is 1:2, and the mass fraction ratio of graphene / carbon nanotube mixture and paraffin oil is 40:100, At a temperature of 50° C., the rotation speed of the high-speed rotary mixer is 600 rpm, and the stirring time is 1.5 h.

[0045] The preparation method of hydrogenated nitrile rubber and sampl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com