Straight channel mesoporous-sapo-34 molecular sieve and preparation method thereof

A-SAPO-34, mesoporous molecular sieve technology, applied in the field of straight-through-channel mesoporous-SAPO-34 molecular sieve and its preparation, can solve the problems of low crystallinity, high cost, poor straightness, etc., and achieve cost reduction and good technical effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

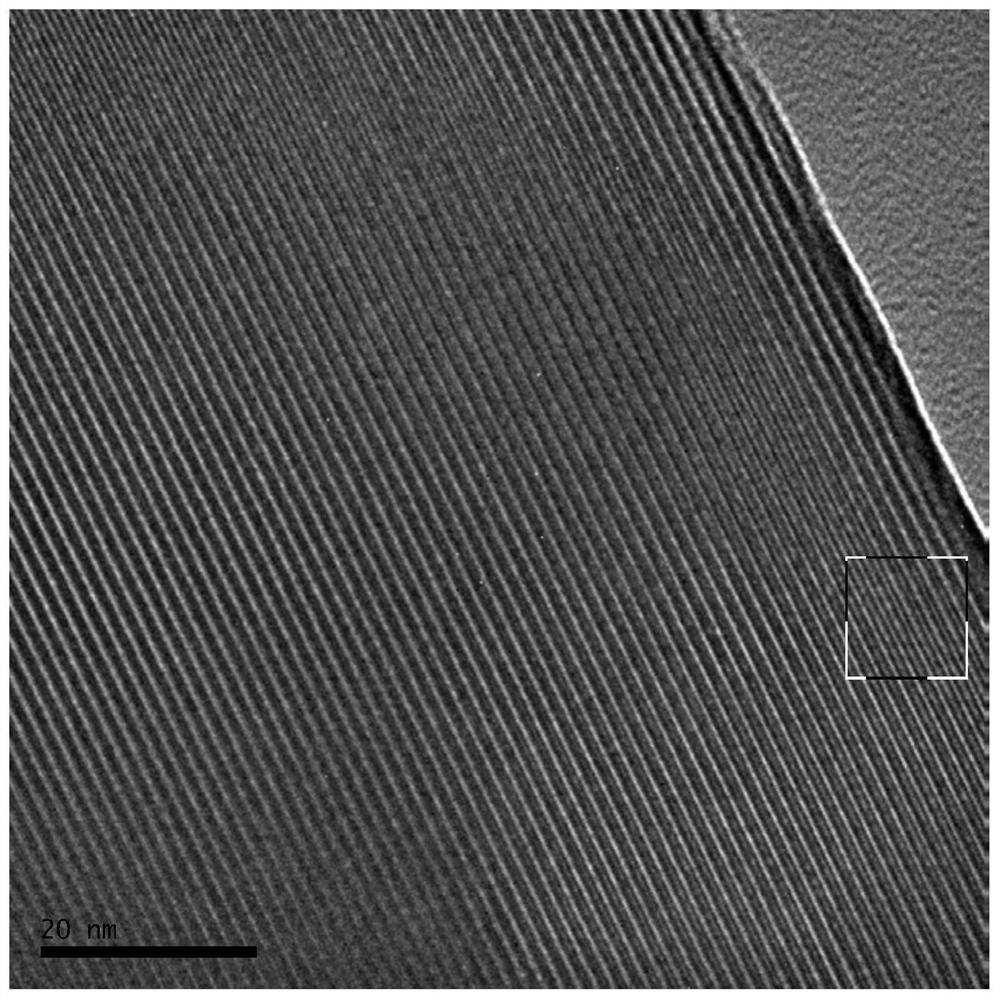

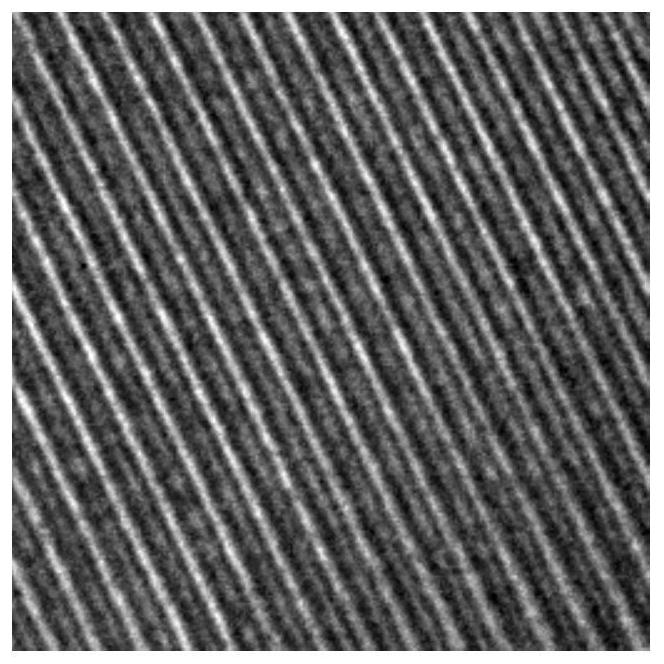

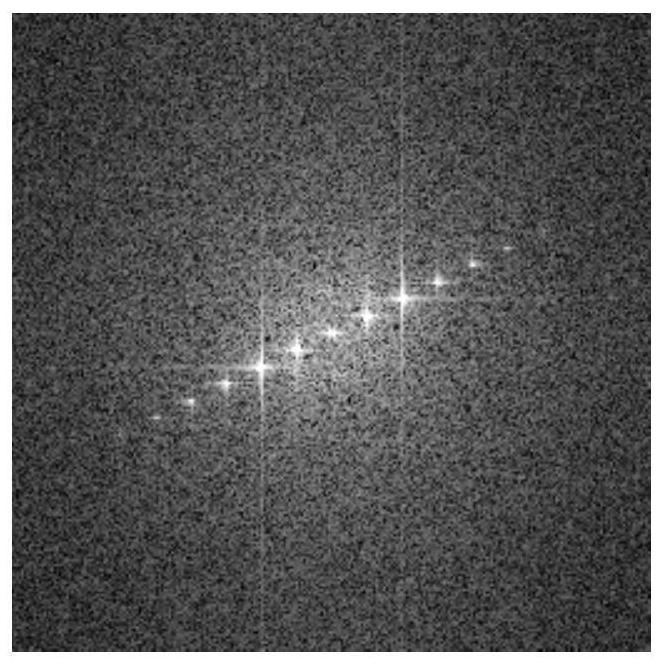

Embodiment 1

[0032] The preparation of straight-through mesoporous SAPO-34 molecular sieve is carried out as follows: first prepare SAPO-34 water-in-oil microemulsion, the aqueous solution of triethylamine (TEA) and phosphoric acid, trin-octylamine is the microemulsion aqueous phase, orthosilicic acid The toluene solution of ethyl ester (TEOS) and aluminum isopropoxide is the oil phase, and the clear microemulsion I is obtained by mixing the two phases of water and oil. The molar ratio of Si:Al:TEA in microemulsion I is 1:1:3; the molar ratio of toluene to tri-n-octylamine to water is 2:1:1; Precursor II was obtained by impregnating SBA-15 molecular sieves with a channel diameter of 4-8 nanometers at a mass ratio of 0.5:1. After aging at 60°C for 1 hour, the precursor II was loaded into a stainless steel reactor, and crystallized at 180°C for 48 hours to obtain a mesoporous SAPO-34 molecular sieve containing a template. After the product was taken out, it was calcined at 550°C for 6 hours...

Embodiment 2

[0034] The preparation of straight-through mesoporous SAPO-34 molecular sieve is carried out as follows: first prepare SAPO-34 water-in-oil microemulsion, the aqueous solution of triethylamine (TEA) and phosphoric acid, trin-octylamine is the microemulsion aqueous phase, orthosilicic acid The toluene solution of ethyl ester (TEOS) and aluminum isopropoxide is the oil phase, and the clear microemulsion I is obtained by mixing the two phases of water and oil. The molar ratio of Si:Al:TEA in microemulsion I is 1:1:3; the molar ratio of toluene to tri-n-octylamine to water is 2:1:1; Precursor II was obtained by impregnating hexagonal MCM-41 with a channel diameter of 2-6 nanometers at a mass ratio of 0.5:1. After aging at 60°C for 1 hour, the precursor II was loaded into a stainless steel reactor, and crystallized at 180°C for 48 hours to obtain a mesoporous SAPO-34 molecular sieve containing a template. After the product was taken out, it was calcined at 550°C for 6 hours to obt...

Embodiment 3

[0036] The preparation of straight-through mesoporous SAPO-34 molecular sieve is carried out as follows: first prepare SAPO-34 water-in-oil microemulsion, the aqueous solution of triethylamine (TEA) and phosphoric acid, trin-octylamine is the microemulsion aqueous phase, orthosilicic acid The toluene solution of ethyl ester (TEOS) and aluminum isopropoxide is the oil phase, and the clear microemulsion I is obtained by mixing the two phases of water and oil. The molar ratio of Si:Al:TEA in microemulsion I is 1:1:3; the molar ratio of toluene to trin-octylamine to water is 2:1:1; The precursor II is obtained by impregnating the pore molecular sieve at a mass ratio of 0.5:1, wherein the mesoporous molecular sieve is a cubic MCM-48 molecular sieve with a pore diameter of 2-4 nanometers. After aging at 60°C for 1 hour, the precursor II was loaded into a stainless steel reactor, and crystallized at 180°C for 48 hours to obtain a mesoporous SAPO-34 molecular sieve containing a template...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com