Through-type mesoporous L-type molecular sieve and preparation method thereof

A technology of mesoporous molecular sieve and molecular sieve, applied in the field of straight-through mesoporous L-type molecular sieve and its preparation, can solve the problems of increased cost, unsuitability for industrialization, complicated synthesis steps, etc., and achieves good technical effect, environmental friendliness, and cost reduction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

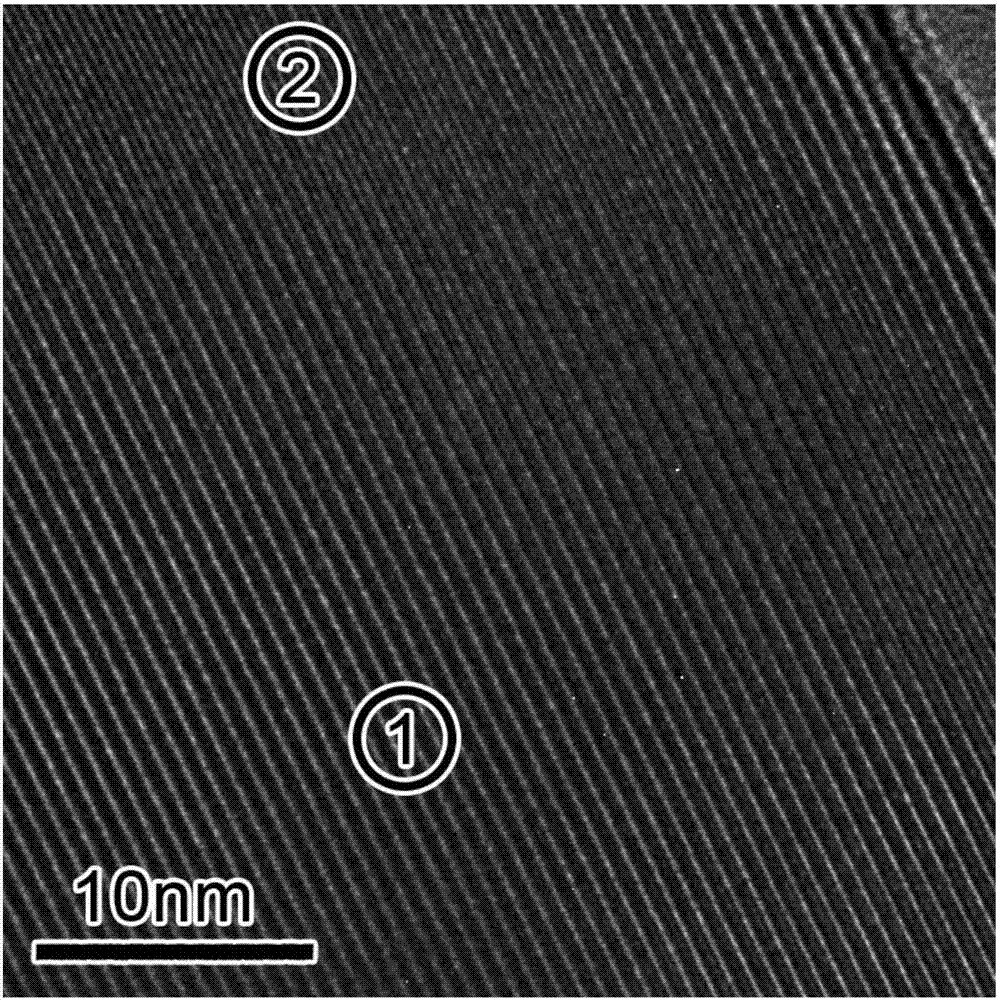

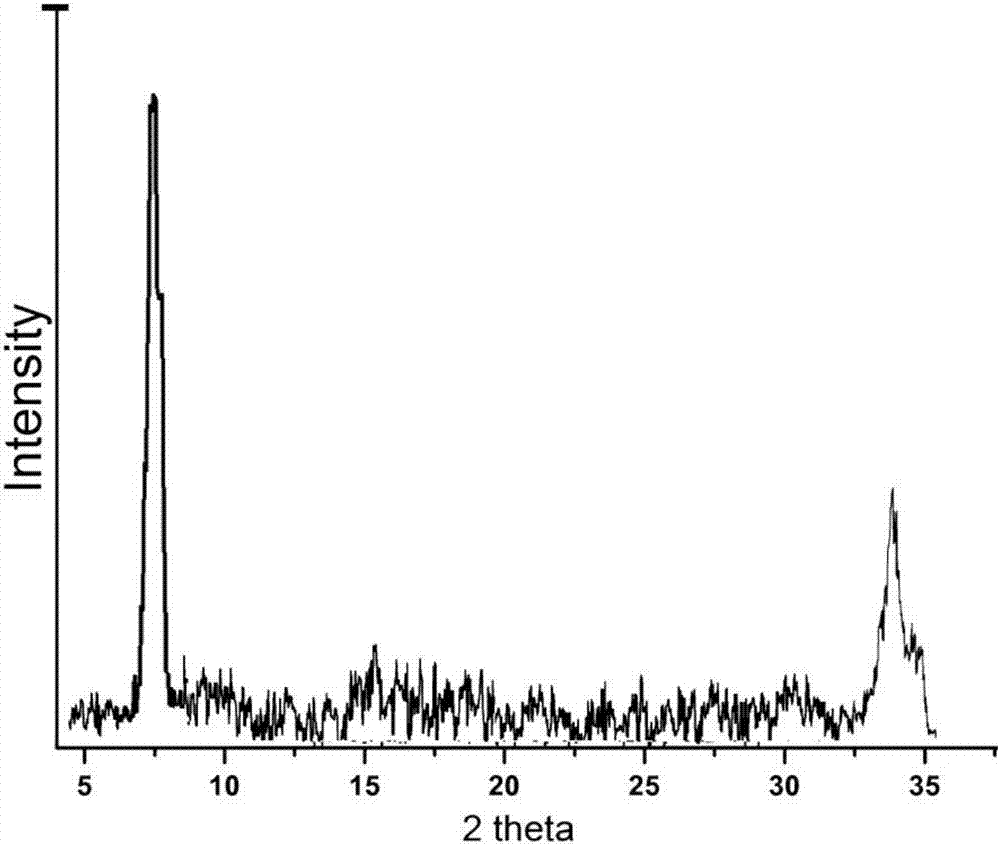

Embodiment 1

[0032] The preparation of the straight-through mesoporous L-type molecular sieve is carried out as follows: first prepare the L-type molecular sieve water-in-oil microemulsion, the aqueous solution of potassium hydroxide and tri-n-octylamine is the microemulsion water phase, tetraethyl orthosilicate (TEOS) and The toluene solution of aluminum isopropoxide is the oil phase, and the clear microemulsion I is obtained by mixing the two phases of water and oil. The molar ratio of Si:Al:KOH in microemulsion I is 10:1:3; the molar ratio of toluene and tri-n-octylamine to water is 2:1:1; Precursor II was obtained by impregnating -15 at a mass ratio of 0.5:1. After aging at 60°C for 6 hours, the precursor II was put into a stainless steel reactor, and crystallized at 150°C for 48 hours to obtain a mesoporous L-type molecular sieve containing a template. After the product is taken out, it is calcined at 550°C for 6 hours to obtain a straight-through mesoporous L-type molecular sieve. ...

Embodiment 2-3

[0035] According to the method in Example 1, only by changing the type of mesoporous molecular sieve, the distribution of mesopores and micropores of straight-through mesoporous L-type molecular sieves can be adjusted, and straight-through mesoporous L-type molecular sieves with different mesopore / micropore void ratios can be obtained. .

[0036] The mesoporous MCM series can be synthesized by conventional technical means in the field.

Embodiment 4

[0038] According to the method of embodiment 1, just change surfactant.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com