Method for producing graphene by voltaic arc negative pressure

A technology of graphene and electric arc, applied in the direction of graphene, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of high working environment requirements, long time consumption, high risk, etc., reduce the number of replacement graphite rods, reduce production costs, risk reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

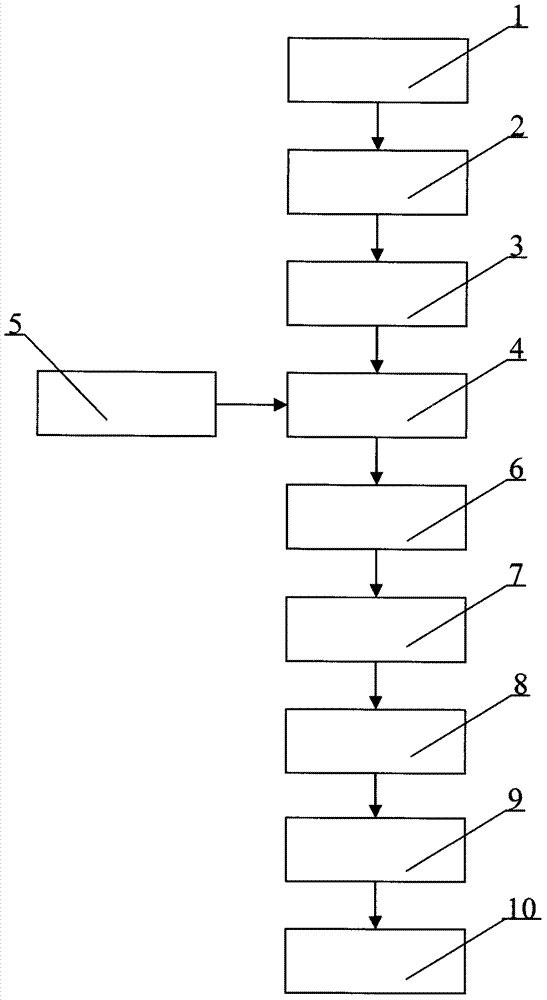

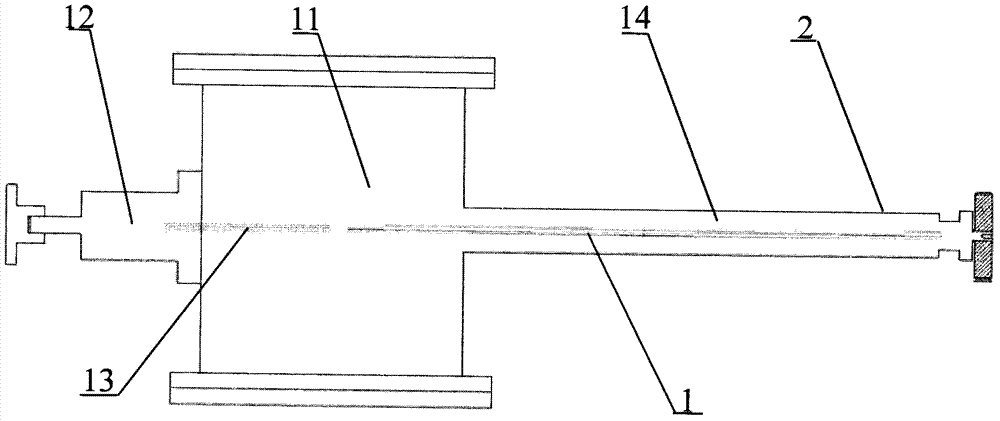

[0012] The first step, lengthening graphite rod 1 is put into cathode propelling device 2, adjusts prolonging graphite rod 1 in cathode propelling device 2, makes the distance between the prolonging graphite rod 1 in cathode 14 and the short graphite rod 13 in anode 12 The constant distance is 1-3 mm to ensure the stability of the preparation current and voltage, and the quality of the prepared graphene is uniform.

[0013] In the second step, vacuumize 3 to extract the air in the vacuum cavity 11, and then clean the pipeline with hydrogen and helium 5 to remove residual air in the pipeline.

[0014] In the third step, the gas 4 is flushed into the vacuum cavity 11, and the pressure value of hydrogen and helium 5 reaches -2×10 -5 MPa, the negative pressure environment meets the pressure required for graphene preparation.

[0015] The 4th step, open arc discharge device, the electric current of regulating current discharge 6 is 140A, and arc discharge device discharges, forms ...

Embodiment 2

[0019] The steps are the same as in Example 1, and the pressure value in the third step is changed to -1.85×10 -5 MPa, the current of the fourth step is changed to 170A, and the graphene product quality is the same.

Embodiment 3

[0021] The steps are the same as in Example 1, and the pressure value in the third step is changed to -1.57×10 -5 MPa, the electric current of the 4th step is changed into 200A, and graphene product quality is identical, and the graphene monolayer thickness 0.355nm that the method for the present invention prepares, size 100~20nm, conductivity 1000~2000s / m, as image 3 The number of layers of graphene shown is distributed between 1 and 3 layers. The above is only an implementation of the feasible embodiments of the present invention. The changes in the range of current and air pressure values made according to the above embodiments are all included in this technical solution. within the scope of protection.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com