Intelligent material crown block system balanced in material distribution

A material distribution and intelligent material technology, applied in the field of industrial manufacturing, to avoid the reduction of equipment life, avoid linkage effects, and have strong calculation and solution accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

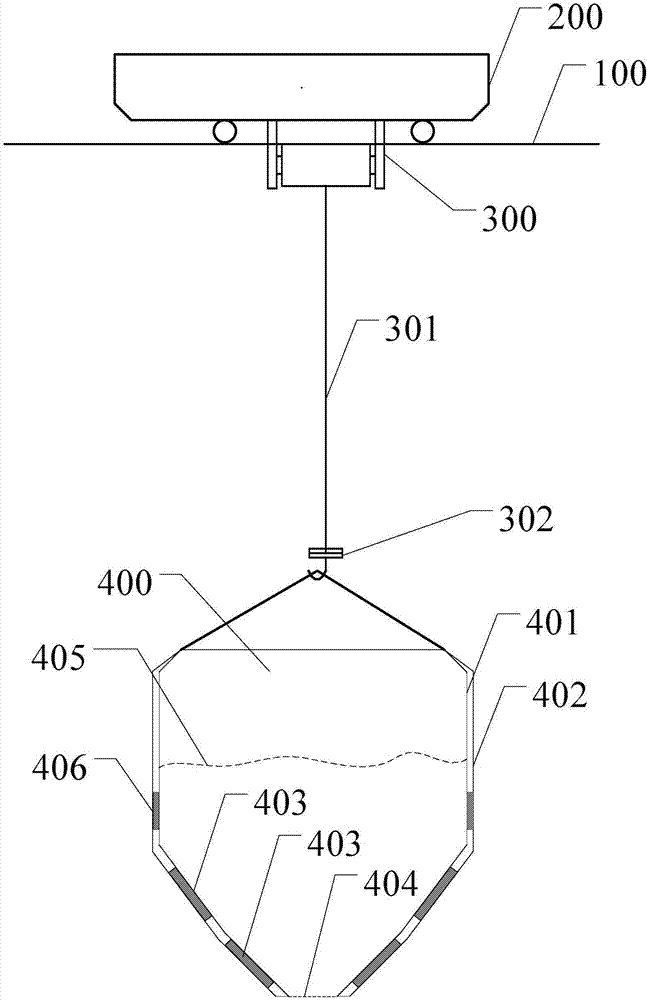

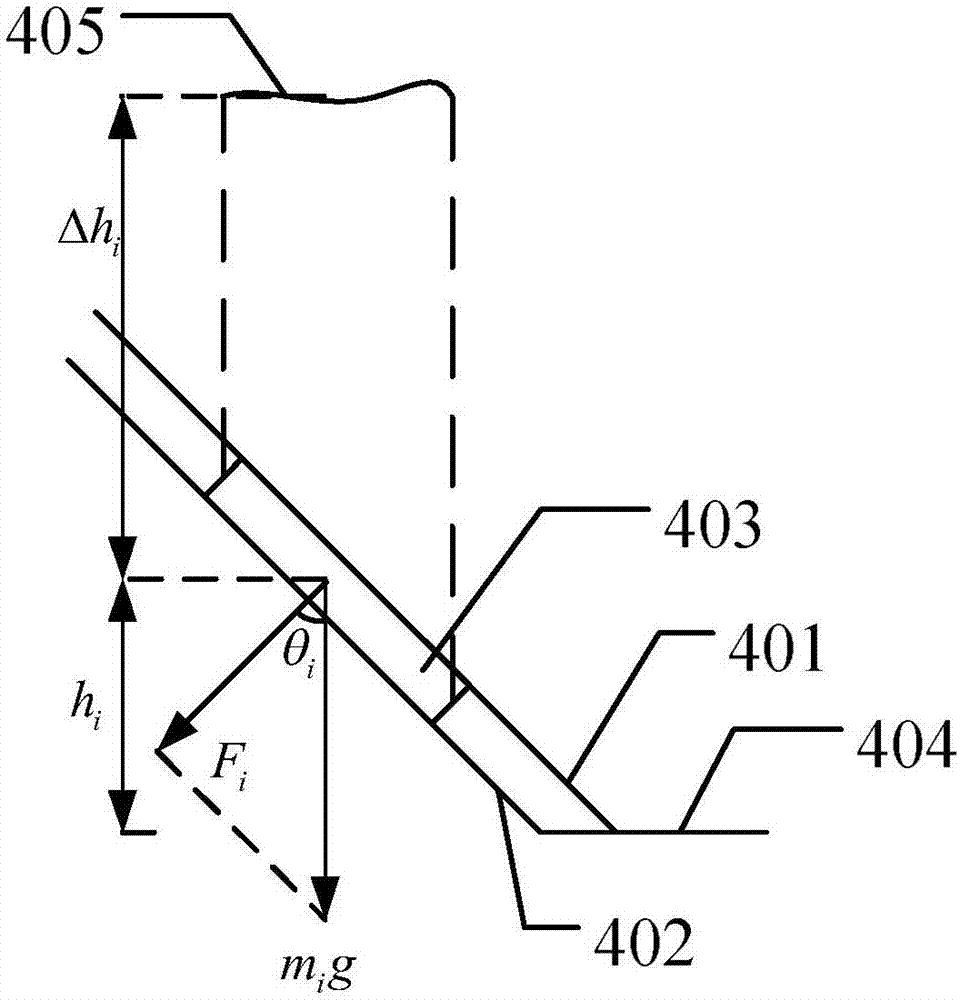

[0026] Such as Figure 1-3 As shown, in the first embodiment of the present invention, an intelligent material crane system with balanced material distribution is provided, and the system includes:

[0027] The material crane 200 is used for distributing materials; the material crane 200 includes a main body of the crane, a hoist 300 arranged on the main body of the crane, a hook 302, and a hook 302 connected between the hoist 300 and the hook 302 The silo 400 hoisted by the sling 301 and the hook 302; the material crane 200 also includes a drive module for traveling the crane;

[0028] Crane track 100, used to carry the material crane 200;

[0029] The crane vibration module 406 is used to vibrate the silo 400 and balance the material distribution in the silo 400;

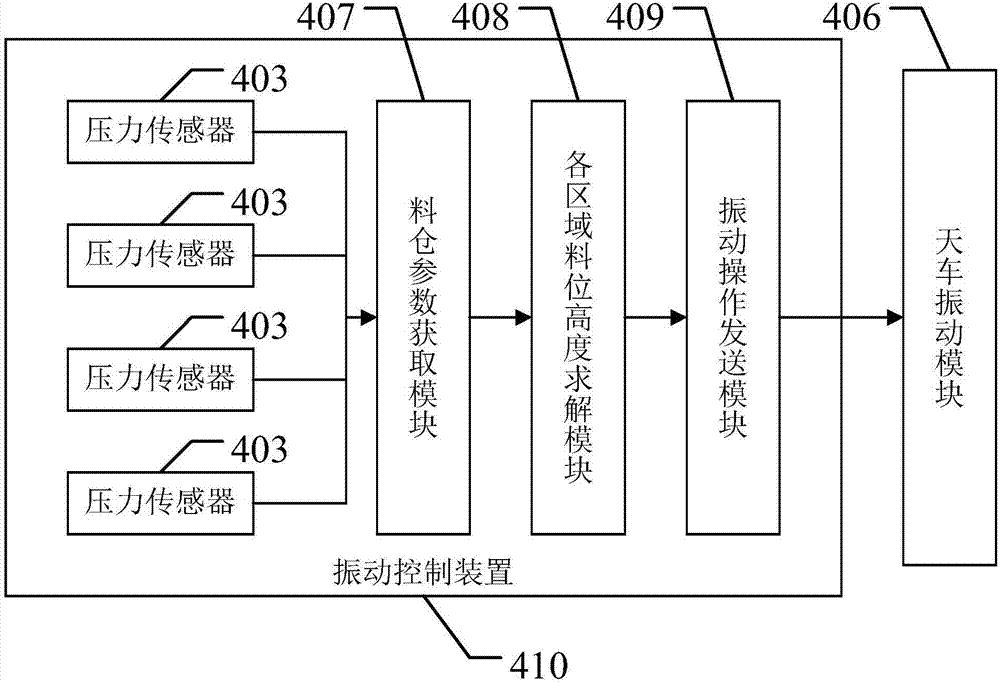

[0030] And a vibration control device 410, configured to collect information about the uni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com