Stamping die for stepped cylindrical parts

A stamping die, cylindrical technology, applied in the direction of forming tools, manufacturing tools, household appliances, etc., can solve the problems of high cost, scattered molds, waste of manpower, etc., to improve efficiency, save operating costs, and reduce labor intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

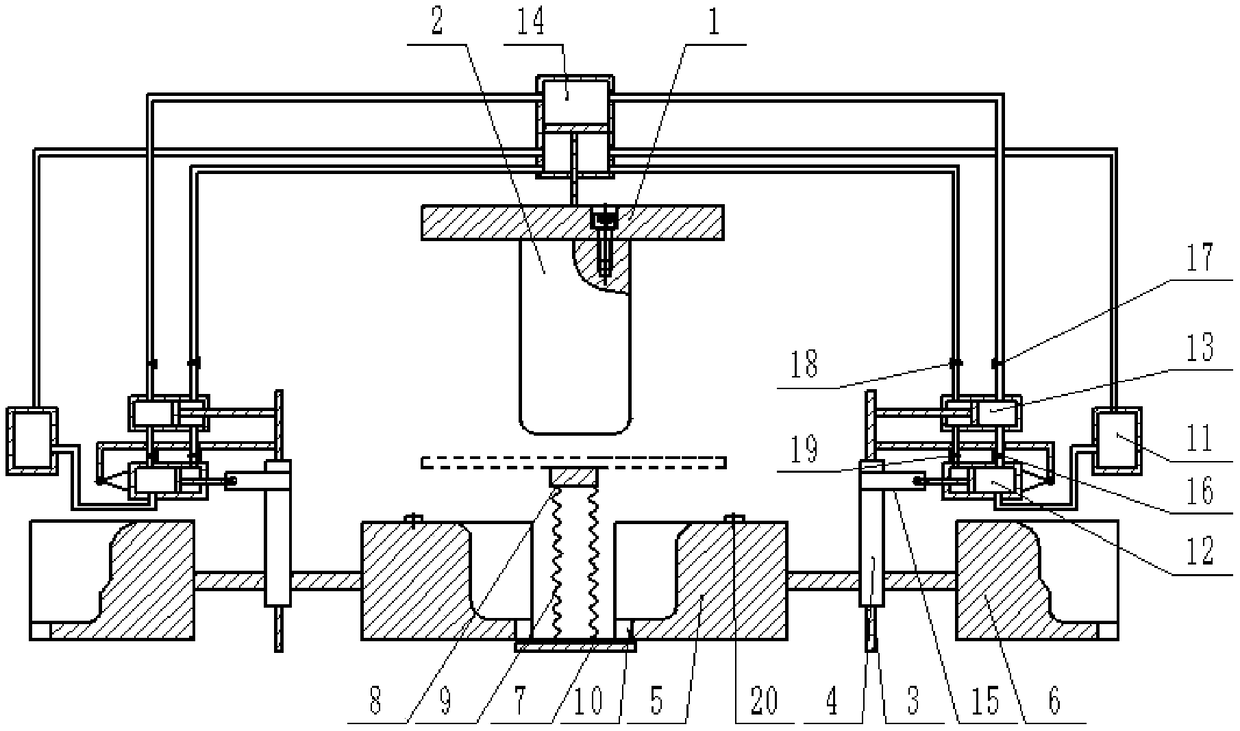

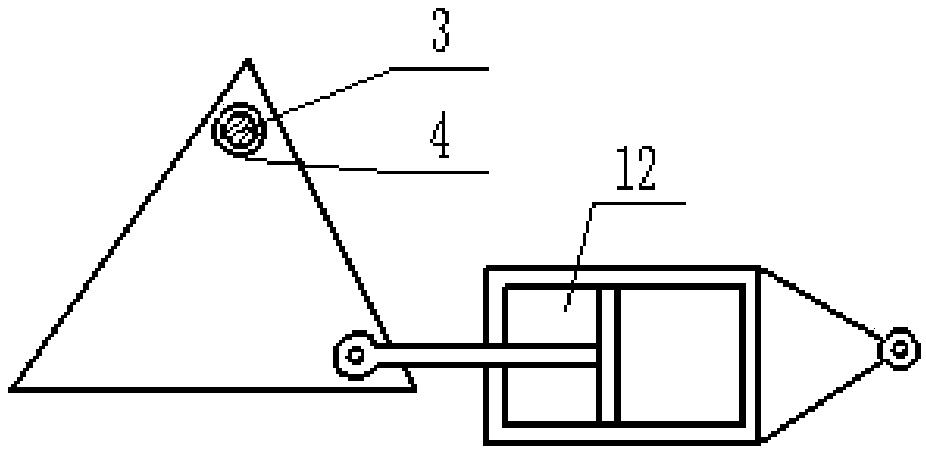

[0023] The utility model relates to a stamping die of a stepped cylindrical part, which comprises a stamping lower die, a stamping upper die, a material return device and a transmission device. Such as figure 1 As shown, the stamping upper die includes an upper template 1 and a punch 2 connected to the lower surface of the upper template 1 by threads, the punch 2 is cylindrical, and a spring washer is installed at the threaded connection to prevent loosening. The stamping lower die includes two punching parts that are symmetrical about the punch 2 axis. The punching part includes a vertical shaft 3. The outside of the vertical shaft 3 is connected with a shaft sleeve 4 through a one-way bearing. The shaft sleeve 4 is welded axially symmetrically with a primary pull Stretching half of the die 5 and half of the stretch shaping die 6. Stretching pin 20 is inserted on the initial drawing die 5 . And the bottoms of the primary stretching die and the stretching and shaping die 6 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com