Bi-piezoelectric stack driving type precision rotary driving device

A rotary drive device and drive-type technology, which is applied in the field of precision engineering, can solve problems such as large structural size, low positioning accuracy, and small stroke, and achieve the effects of high displacement resolution, low drive power, and large output force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

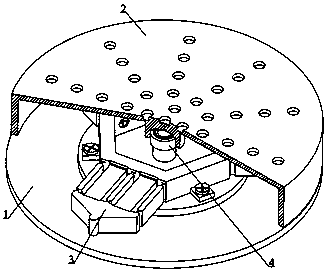

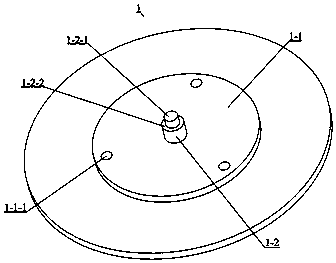

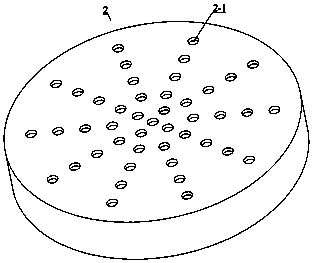

[0053] see Figure 1 to Figure 14 As shown, the dual piezoelectric stack-driven precision rotary driving device of the present invention includes a support base 1 , a rotating table 2 , a stator assembly 3 and a bearing 4 . The supporting base and the rotating platform are connected through bearings, the supporting base and the stator assembly are connected through bolts, the rotating platform and the stator assembly are contacted and matched through the front end of the driving foot, and the bearing is in interference fit with the supporting base and the rotating platform. When the excitation electrical signal acts on the stacked piezoelectric element, the stacked piezoelectric element generates axial elongation based on the inverse piezoelectric effect, causing the driving foot to generate tangential displacement, driving the rotating table to generate rotational motion, and changing the driving voltage The direction and timing of the rotating table can be controlled to perf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com