Blind hole thread machining control method and device, processor and storage medium

A thread processing and control method technology, which is applied in the field of control devices, blind hole thread processing control methods, processors and storage media, can solve the problems of cumbersome programming process and error-prone, and achieve widely popularization and application value, simple and reliable control Improvement of performance and processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

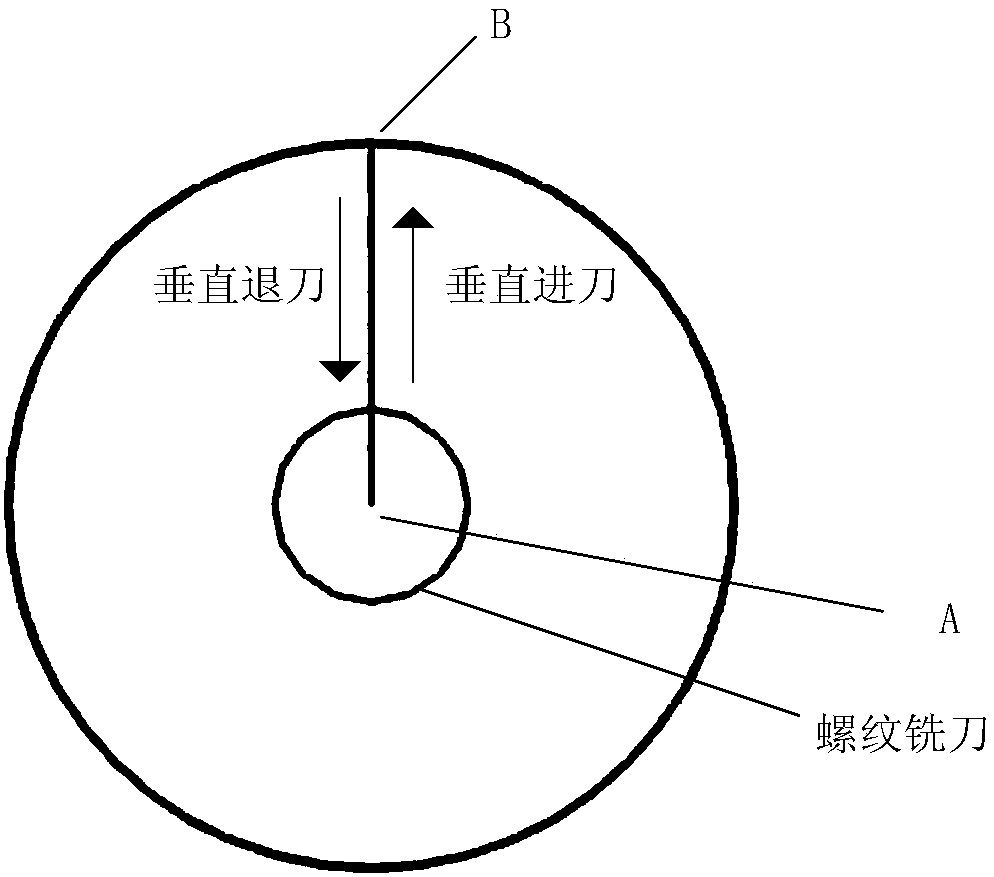

[0053] A preferred embodiment of the present invention provides a blind hole thread processing control method, which is used for thread milling processing of blind holes with a single aperture and multiple positions. figure 1 , the control method of this embodiment includes:

[0054] Step S100, draw the thread processing points respectively corresponding to the plurality of blind holes in the graphical interface software;

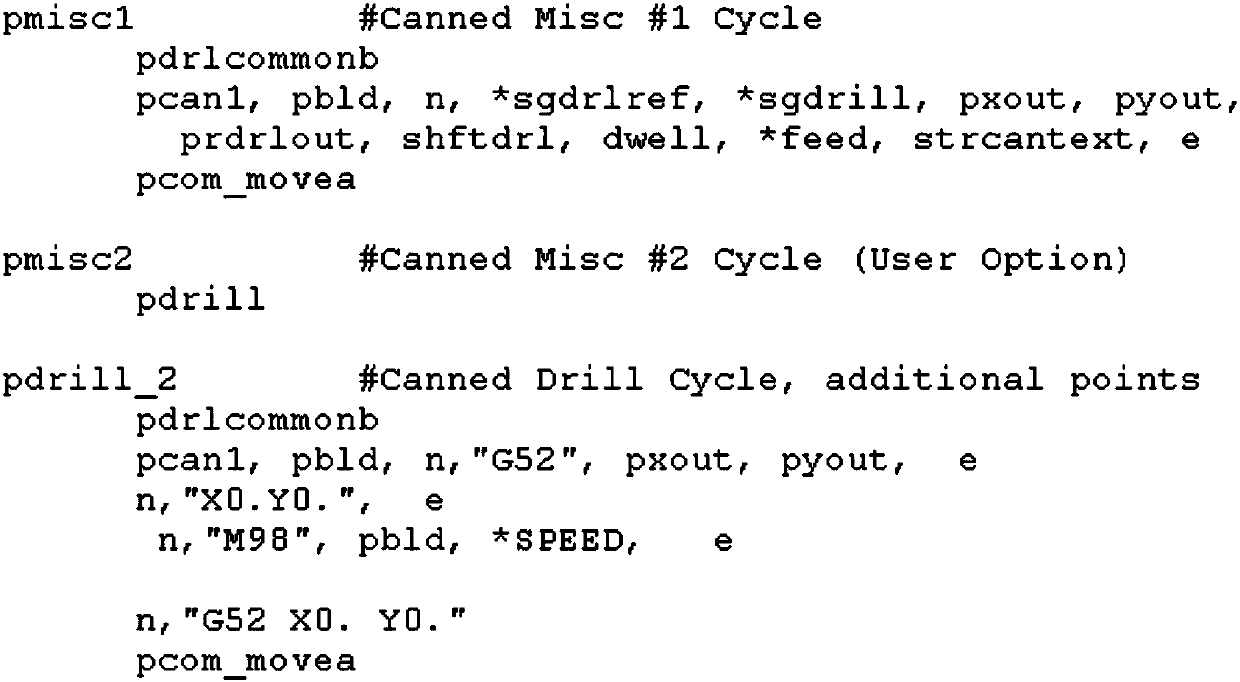

[0055] Step S200, setting the parameter variable assignment for the subroutine call;

[0056] Step S300, calling a subroutine to generate a NC machining instruction for NC machining;

[0057] In step S400, the numerical control system is driven to perform thread milling o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com