Active information assembly test device and test method

A technology for component testing and source information, applied to measurement devices, using digital measurement technology to measure, measure electricity, etc., can solve problems such as discovery, component damage, and test misjudgment, and achieve the effect of convenient use and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

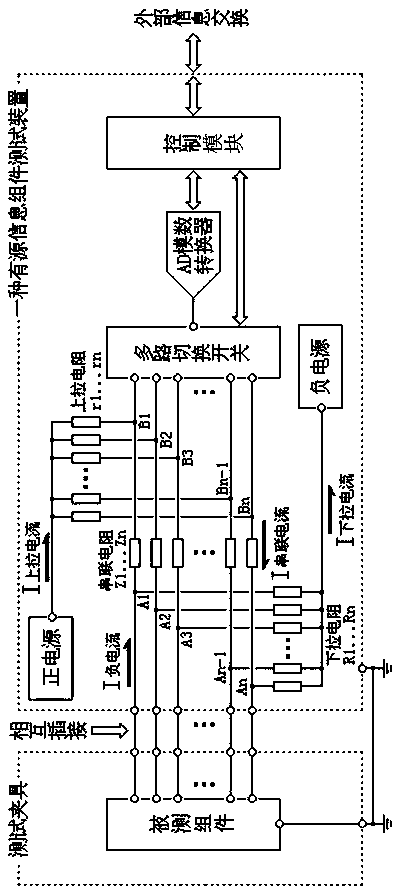

[0047] Such as figure 1 As shown, an active information component testing device includes n test input interfaces, which are connected to the n input terminals of the m-way switch one by one; the n test input interfaces are connected to n pull-down resistors R one by one to the negative power supply, and n test input interfaces are connected to the n pull-down resistors R to form n A nodes; the n input terminals of the m-way switch are connected to the positive power supply, and the n input terminals are connected with n pull-up resistors r to form n B nodes; there are series resistors Z between the one-to-one corresponding A nodes and B nodes, and there are n series resistors Z in total; Said n is a natural number greater than 1, and said m is a natural number greater than or equal to n; the parameter setting of said positive power supply, negative power supply, pull-up resistor r, series resistor Z and pull-down resistor R should meet the requirements when testing the compon...

specific Embodiment 2

[0049] On the basis of specific embodiment 1, it also includes a control module, the control module includes a first controller connected to the m-way switch, capable of selecting and controlling the switching action of the switch of the m-way switch, and realizing the selection of the selector switch Switch automatically.

specific Embodiment 3

[0050] On the basis of specific embodiment 1 or 2, also comprise the AD analog-to-digital converter that signal input end is connected with the output end of m road switch; AD analog-to-digital converter samples the signal of selected channel, and outputs the sampling result ; Also includes a control module, the control module includes a second controller, connected to the control terminal of the AD analog-to-digital converter, and controls the AD analog-to-digital converter to collect the output signal of the m-way switch.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com