Method for in situ performance test of all components in particle reinforced composite material

A particle-reinforced, composite material technology, applied in analytical materials, measuring devices, instruments, etc., can solve the problems of difficult analysis, unable to obtain quantitative conclusions, and unable to find effective judgment methods, and achieve the effect of improving experimental accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

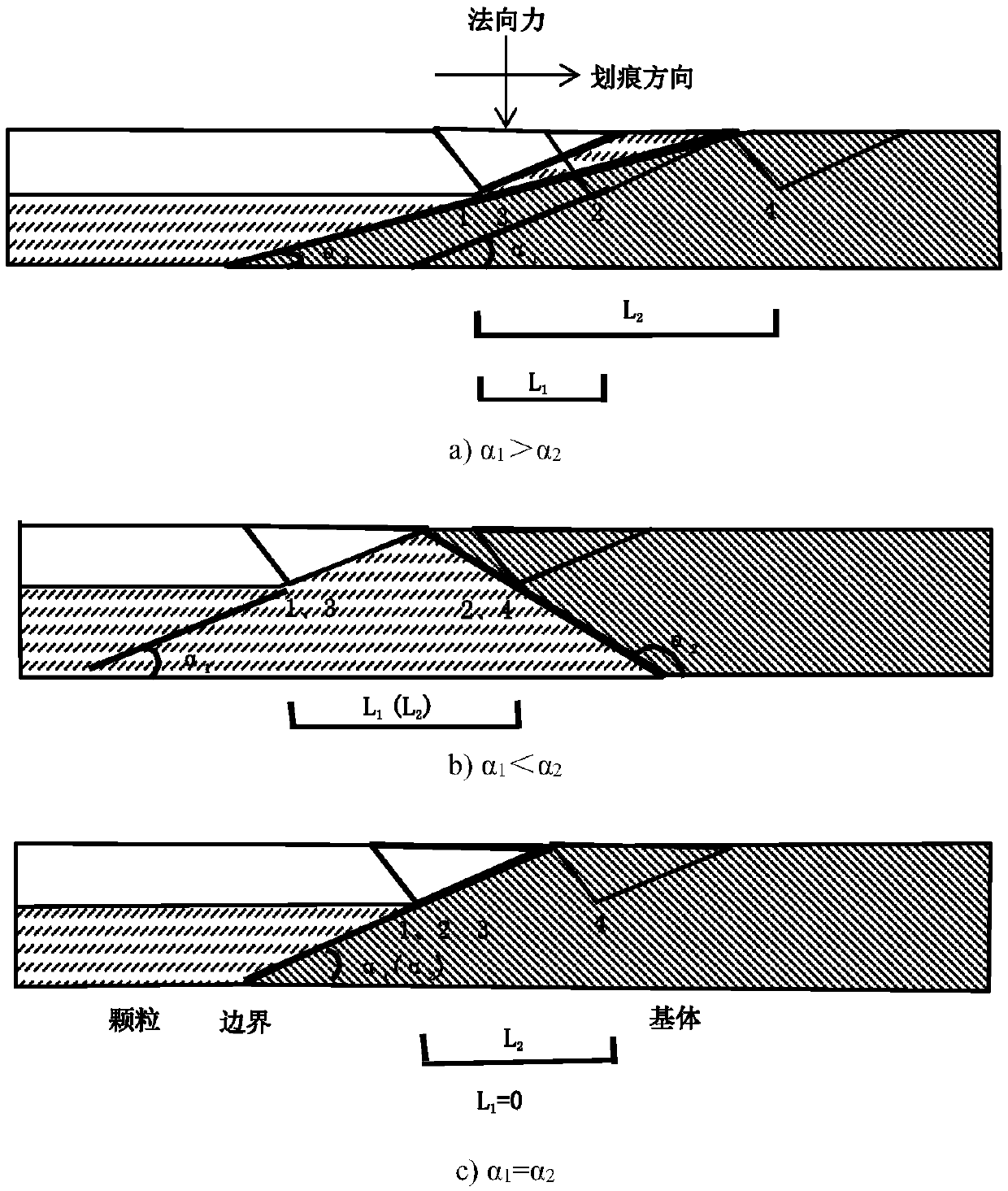

[0024] Example 1 measures zirconia (ZrO 2 ) Particle-reinforced polymethyl methacrylate (PMMA) components in-situ elastic properties

[0025] Applying a test method for the in-situ performance of each component of particle-reinforced composite materials to obtain ZrO without the influence of peripheral effects 2 Particles enhance the in-situ elastic properties of PMMA components. First, use the optical microscope of the nano-indenter to locate a certain range including regular ZrO 2 The circular area of the particle, the center point of the circular area is ZrO 2 Particle center, radius 50 microns. The P value of the feedback adjustment is 5000, the I value is 500, and the D value is 1000, and the change speed of the force during the adjustment is ±0.2 mN / s. The starting position of the scratch is the center of the circular area, the angle between adjacent scratch paths is 30°, a total of 12 lines, the pre-pressing depth is 2 microns, the pressing speed is 0.2 microns / sec...

example 2

[0026] Example 2 Measurement of silicon carbide (SiC) particle reinforced aluminum (Al) components in-situ elastic properties

[0027] Apply a test method for the in-situ performance of each component of particle-reinforced composite materials to obtain the in-situ elastic properties of SiC particle-reinforced Al components without the influence of peripheral effects. A circular area of regular SiC particles, the center point of the circular area is the center of the SiC particle, and the radius is 100 microns. The P value of the feedback adjustment is 6000, the I value is 550, and the D value is 1000. The change speed of the force during the adjustment is ±0.3 mN / s. The starting position of the scratch is the center of the circular area, the angle between adjacent scratch paths is 30°, a total of 12 lines, the pre-pressing depth is 1 micron, the pressing speed is 0.2 micron / s, and the scratching speed is 4 micron / s. From the center along the radial direction, the SiC parti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com