A Vision System for Optimal Calibration of Laser Ranging

A vision system, laser ranging technology, applied in measuring devices, optical devices, instruments, etc., can solve the problem of high accuracy level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The following embodiments will further illustrate the present invention in conjunction with the accompanying drawings.

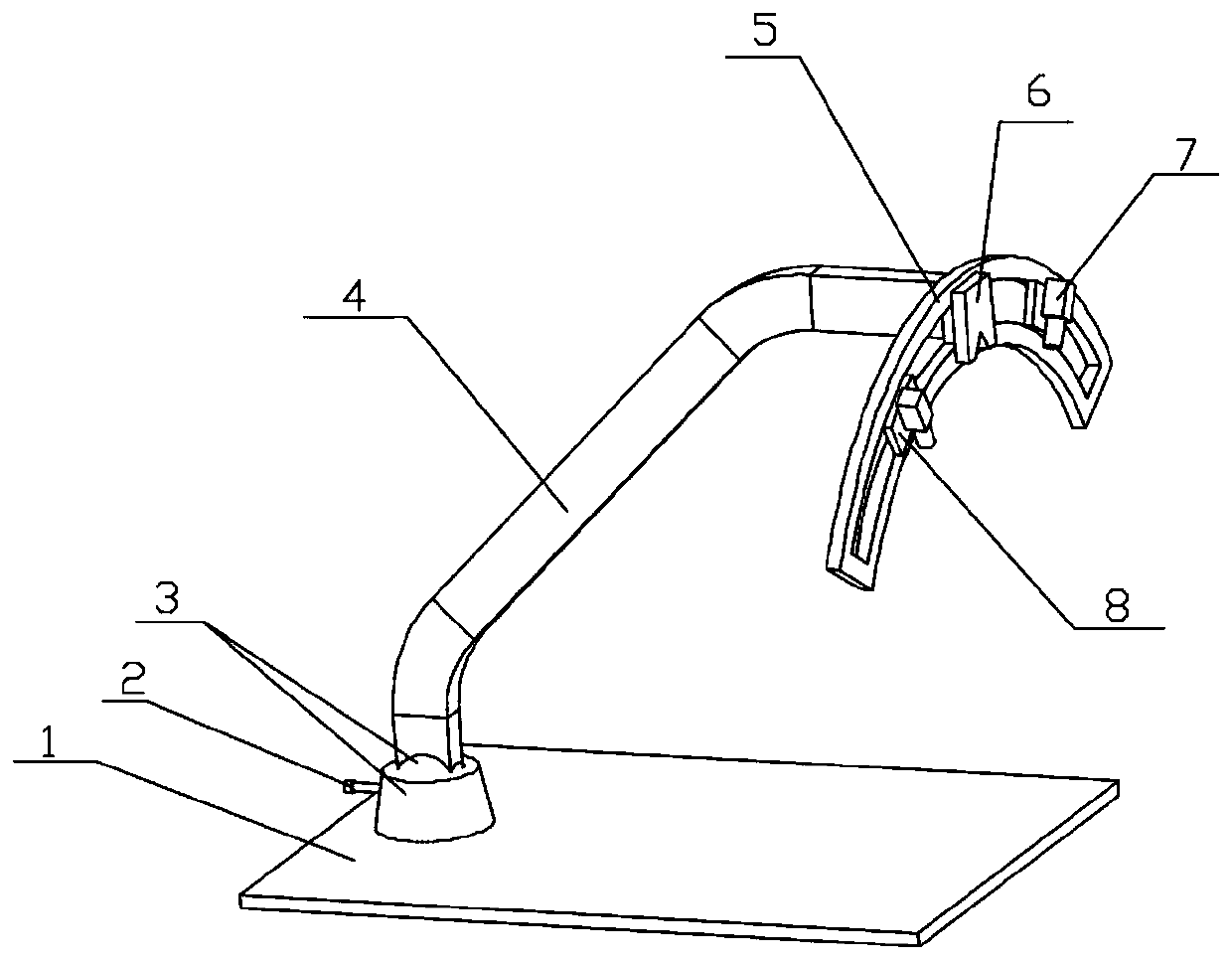

[0040] see Figure 3-6 , the embodiment of the present invention is provided with base 1, fixing bolt 2, spherical hinge 3, system bracket 4, arc frame 5, slider 8, camera 7 and laser displacement sensor 6; Said laser displacement sensor 6, camera 7 and slider Block 8 is fixed on the arc frame 5, the upper end of the system support 4 is fixed on the arc frame 5, the bottom end of the system support 4 is fixed on the base 1, and the bottom end of the system support 4 is connected with the fixing bolt 2 by a spherical hinge 3, The fixing bolt 2 is fixed on the base 1; the camera 7 is fixed on the slider 8, and the angle of the camera 7 can be adjusted on the arc-shaped frame 5.

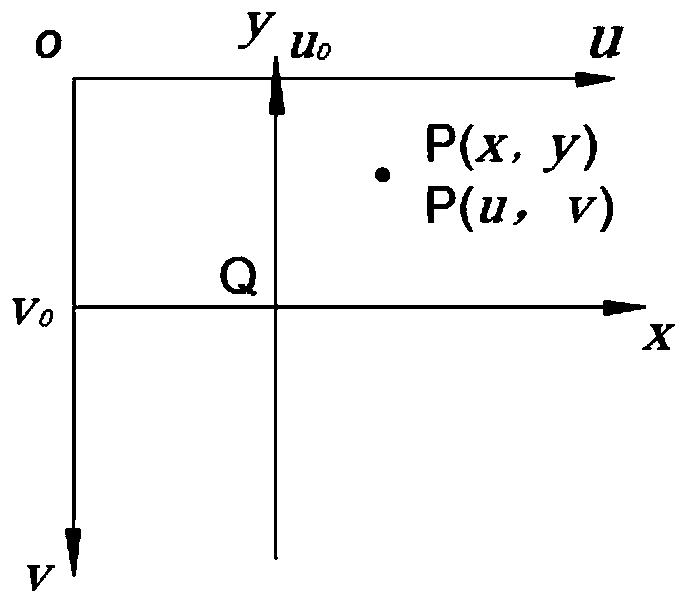

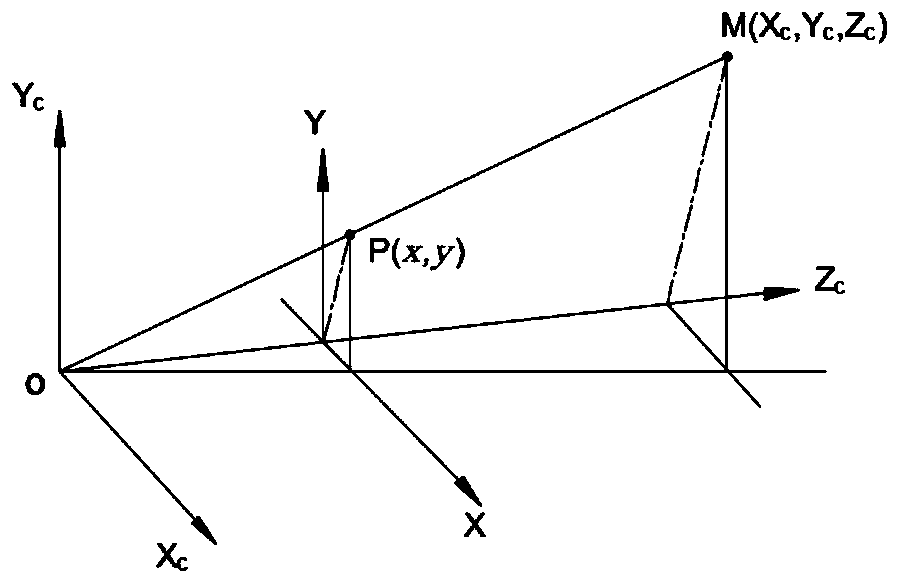

[0041] When performing camera calibration, the laser displacement sensor measures the distance of the feature point, denoted as s, and the angle λ between the laser displaceme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com