Iron roughneck torque dynamic remote visual assembly

An iron driller, dynamic technology, used in drill pipe, drill pipe, drilling equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

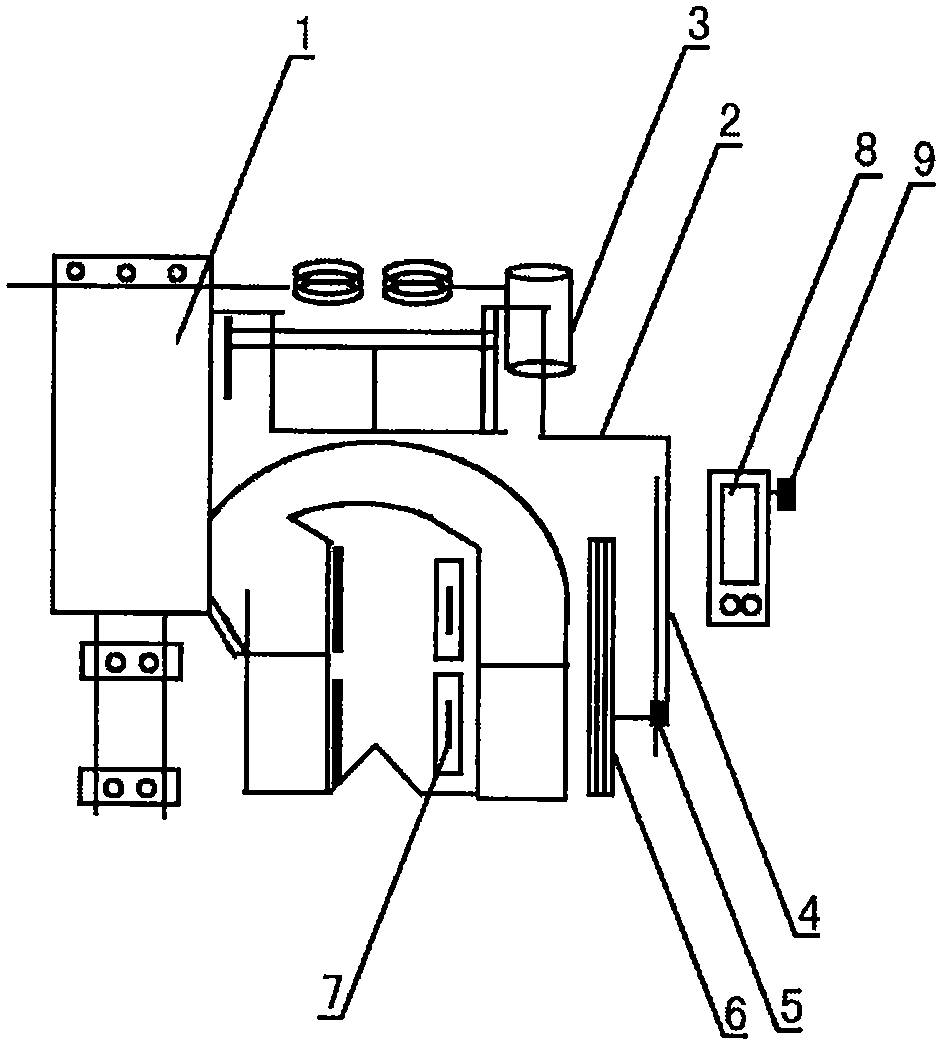

[0012] Embodiment: as shown in the accompanying drawing. An iron driller torque dynamic remote visual assembly, comprising an iron driller body (1), on the side of the body (1) spinner, a hanging positioning column (2) including an angle adjuster (3), a lift type Vertical rod (4), movable guide block (5), long monitoring probe (6), torque tightness sensing device (7) is located at the inner end of the tong, and the sensing device is used when the tong head holds the drill pipe tightly and twists and rotates during operation (7) The detection data is transmitted to the display device (8) of the remote control system, and at the same time, the monitoring probe (6) is moved to the side of the drill pipe to provide a visual picture for the operator.

[0013] An iron driller's torque dynamic remote visual component is provided with a prompting device (9) to issue a corresponding prompt when the make-up / breakout is in a completed state.

[0014] An iron driller torque dynamic remot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com