Wet area wall face wooden product mouldproof technology

A technology for wood products and wet areas, used in building components, building insulation materials, buildings, etc., can solve problems such as erosion of wall decoration materials, damp walls, moldy wood products, etc., to ensure cleanliness and health, and is conducive to human health. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

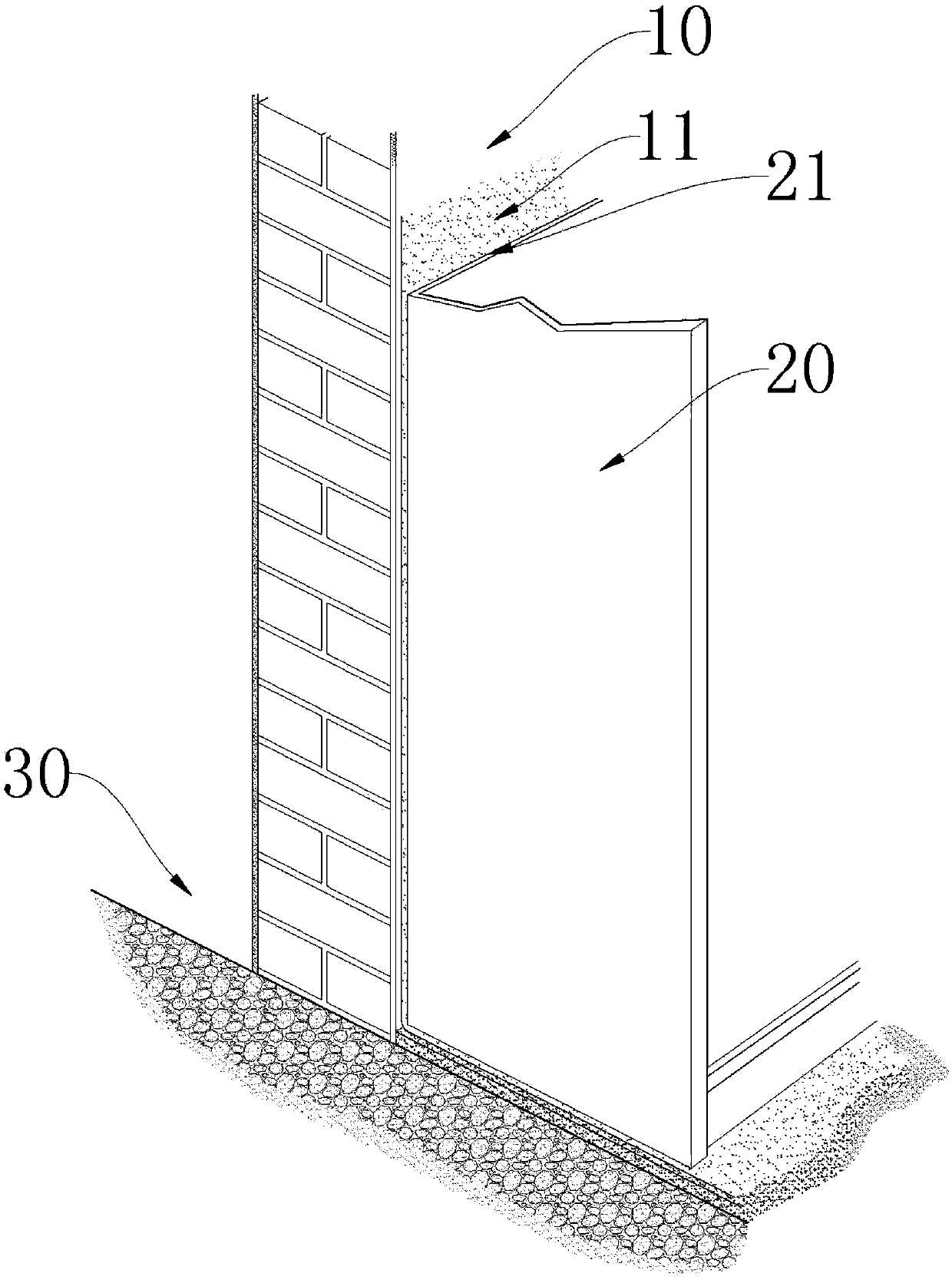

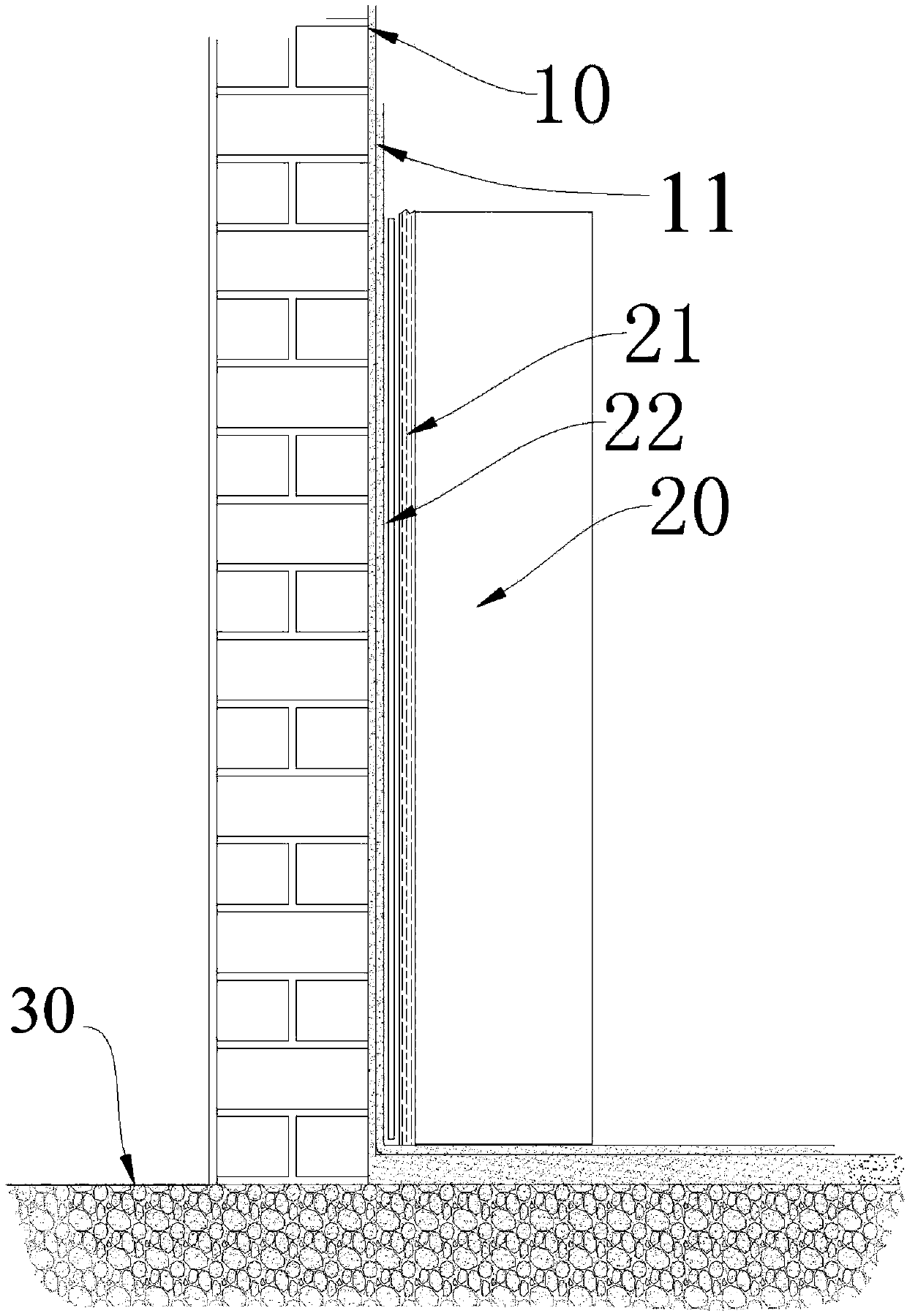

[0022] The idea, specific structure and technical effects of the present invention will be further described below in conjunction with the accompanying drawings, so as to fully understand the purpose, features and effects of the present invention.

[0023] refer to figure 1 with figure 2 , the mildew-proof process for wall wood products in the wet area of the present invention, carries out moisture-proof treatment to the back of the wall body 30 in the wet area and the cabinet body 20 close to the back, comprising the following steps:

[0024] Step 1: Treat the back of the wall with 10 base layers, remove the hollow, soak the white powder layer on the wall with water, and scrape off the wall skin. Use a cutting machine to cut and remove according to the size of the hollow drum to remove hidden dangers of cracks in the future. If the wall is leveled with large white putty instead of white cement, and the base is not firm and easy to pulverize, it must be removed;

[0025]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com