Automatic follow-up clamping device for assembly production line

An assembly line and clamping device technology, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of large number of bolts, unfavorable production line assembly efficiency, and high labor intensity of operators, so as to achieve simple operation and reduce labor strength and improve the efficiency of assembly work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

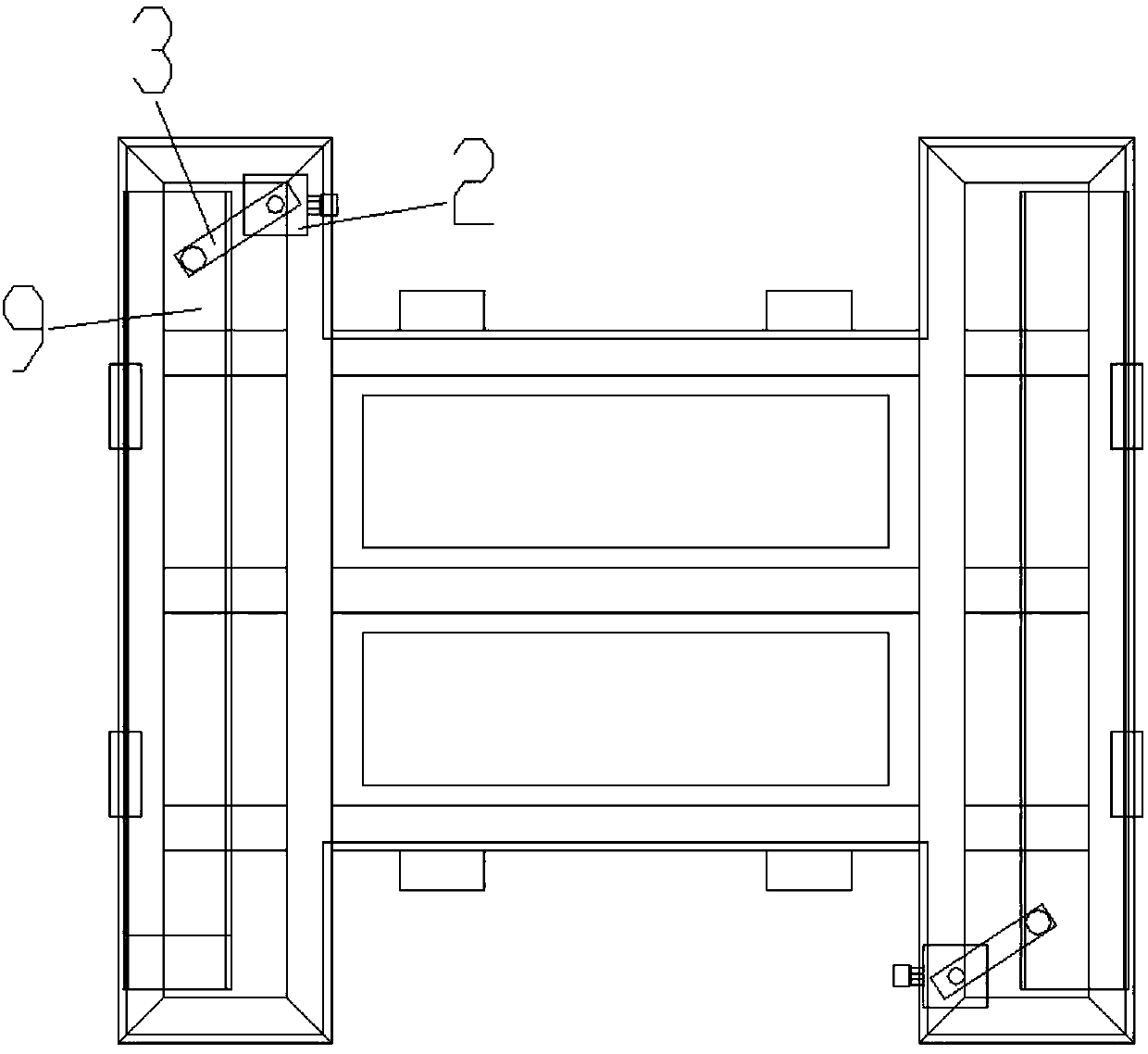

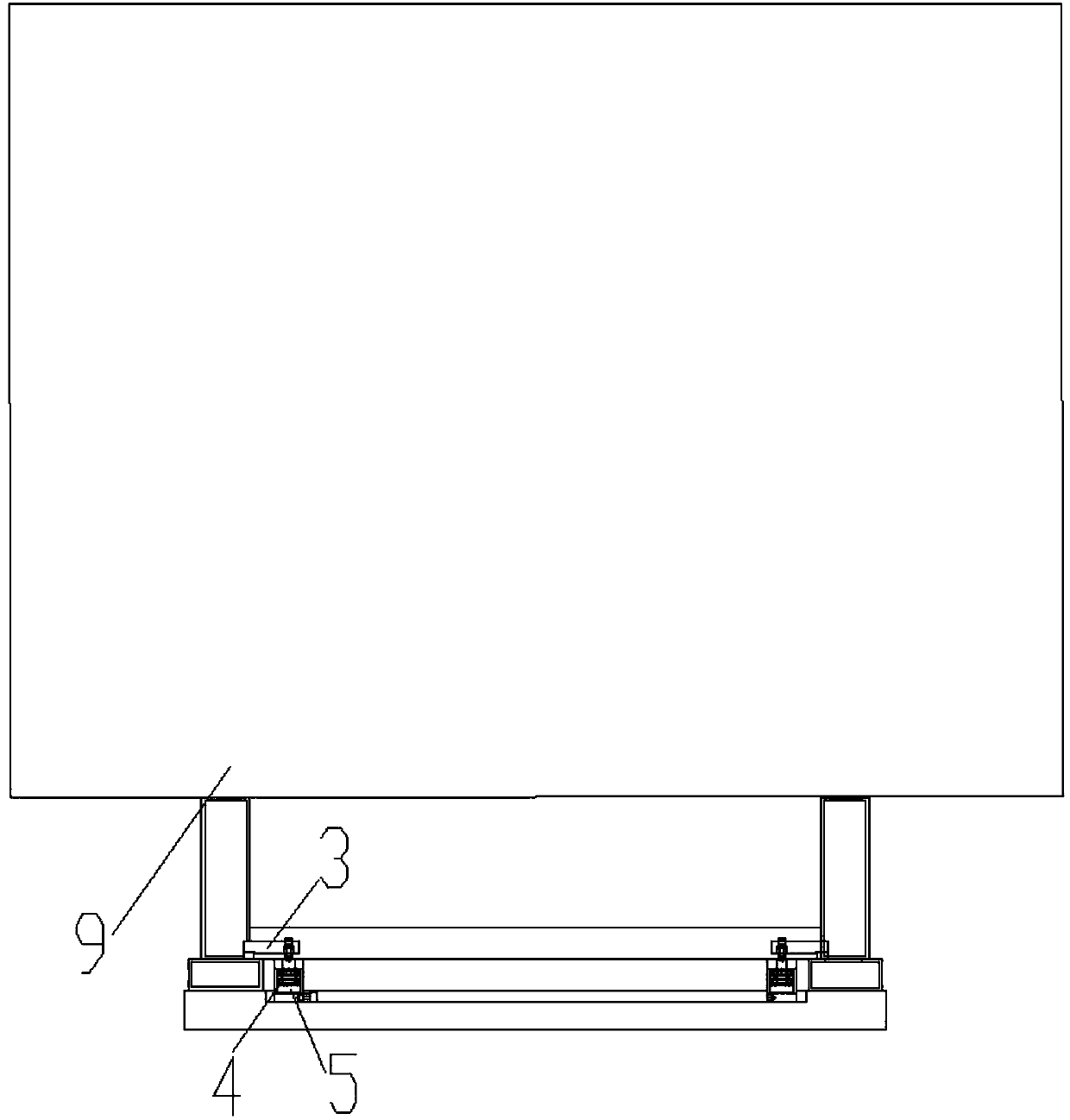

[0019] Attached below Figure 1-7 The present invention is described further:

[0020] An automatic accompanying clamping device used on an assembly line. Clamping swing angle hydraulic cylinders 2 are respectively provided on both sides of a product transition tray 1, and the outer end of the output shaft of the clamping swing angle hydraulic cylinder 2 is connected to a clamping plate. 3. The inner end is connected to the piston 5. The disc spring 4 is located in the inner cavity of the clamping swing angle hydraulic cylinder 2 and is sleeved on the outer periphery of the output shaft. The opposite side of the piston 5 is a hydraulic chamber. The side wall of the hydraulic chamber is detachably connected with A self-sealing quick-change butt joint 6 , the self-sealing quick-change butt joint 6 is connected to a hydraulic hose 7 , and the hydraulic hose 7 is connected to a hydraulic drive device 8 . The clamping plate 3 is connected to the outer end of the output shaft by bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com