Intelligent aluminum alloy sectional material forming machine

A technology of aluminum alloy profiles and forming machines, which is applied in the field of intelligent aluminum alloy profile forming machines, can solve the problems of poor protection effect of workers, poor effect of exhaust gas passing, and low degree of intelligence, so as to improve the effect of dust prevention, Improve the anti-slip effect and improve the effect of intelligence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

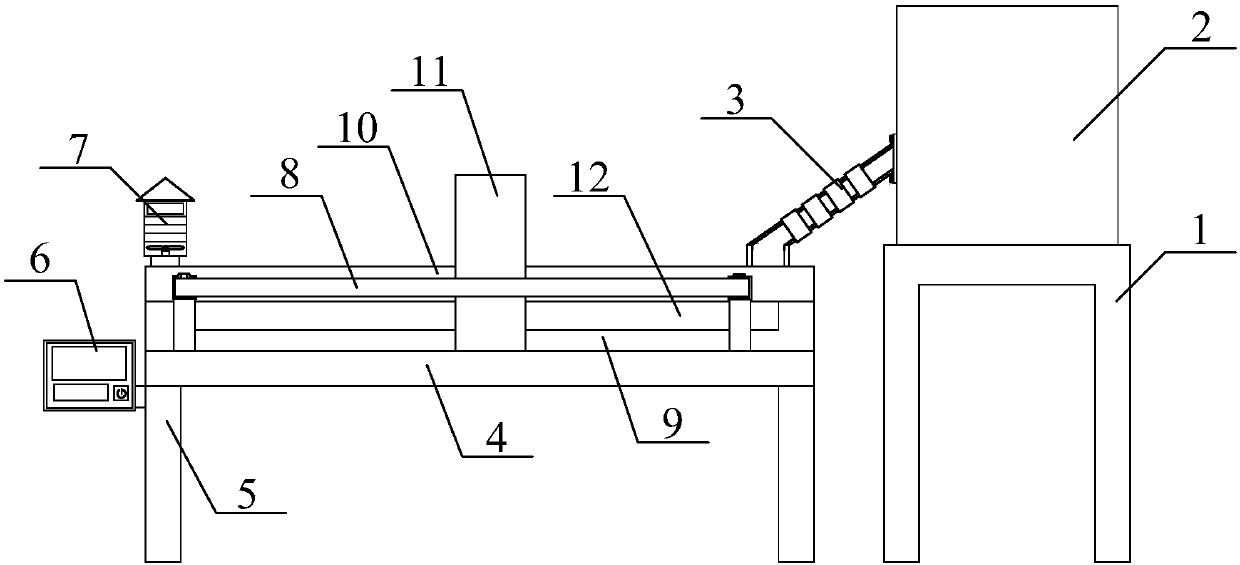

[0030] as attached figure 1 to attach Figure 5 shown

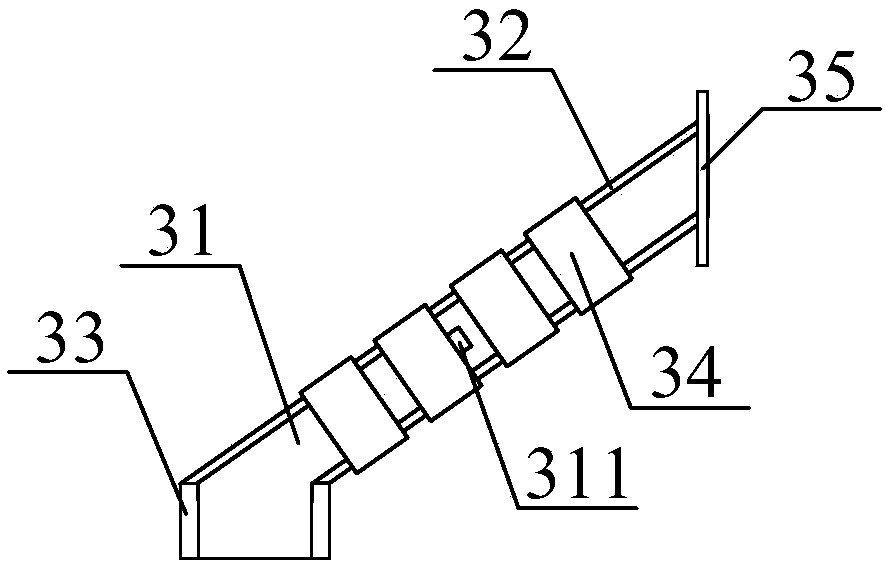

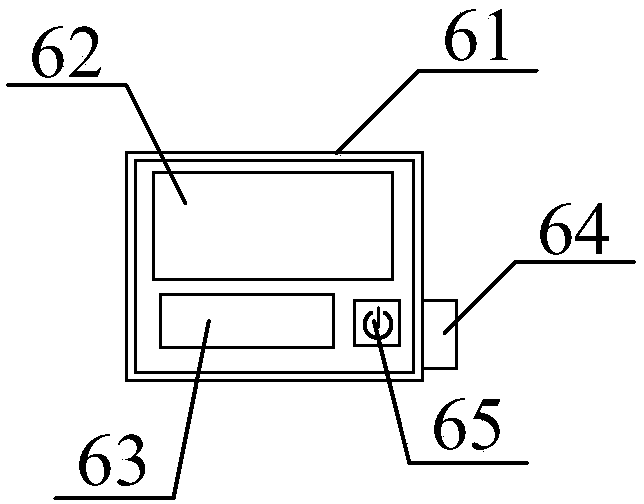

[0031] The invention provides an intelligent aluminum alloy profile forming machine, which includes a frame 1, a hot-melt machine 2, a thermal insulation and heating guide structure 3, a workbench 4, support legs 5, an intelligent control device 6, a degassing structure 7, a protective Frame structure 8, forming frame 9, upper mold 10, lifting frame 11 and forming groove 12, described hot-melt machine 2 bolts are installed on the top of frame 1; 2 connected, the other end is installed on the upper part of the upper mold 10, and connected to the forming groove 12; the workbench 4 is set on the left side of the frame 1; the support leg 5 is longitudinally welded on the lower part of the workbench 4 At the four corners; the bolts of the intelligent control device 6 are installed on the left side of the workbench 4; the degassing structure 7 is welded on the upper left side of the upper mold 10 and connected with the formin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com