Full-automatic production line system for gold ingots and silver ingots

A fully automatic, production line technology, applied in ingot workshops, metal processing equipment, manufacturing tools, etc., can solve the problems of harsh working environment, waste of gold and silver ingot costs, high labor intensity, etc., and achieve the effect of low labor intensity of employees

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

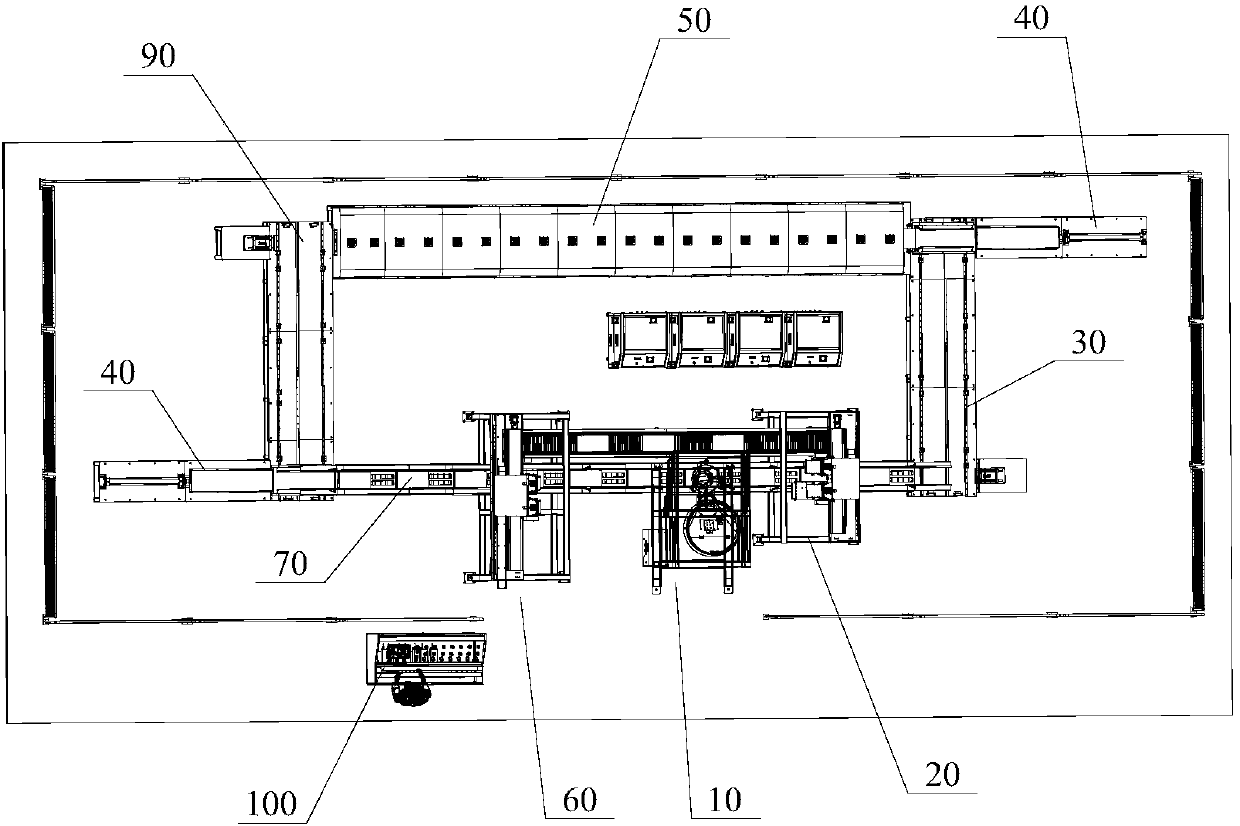

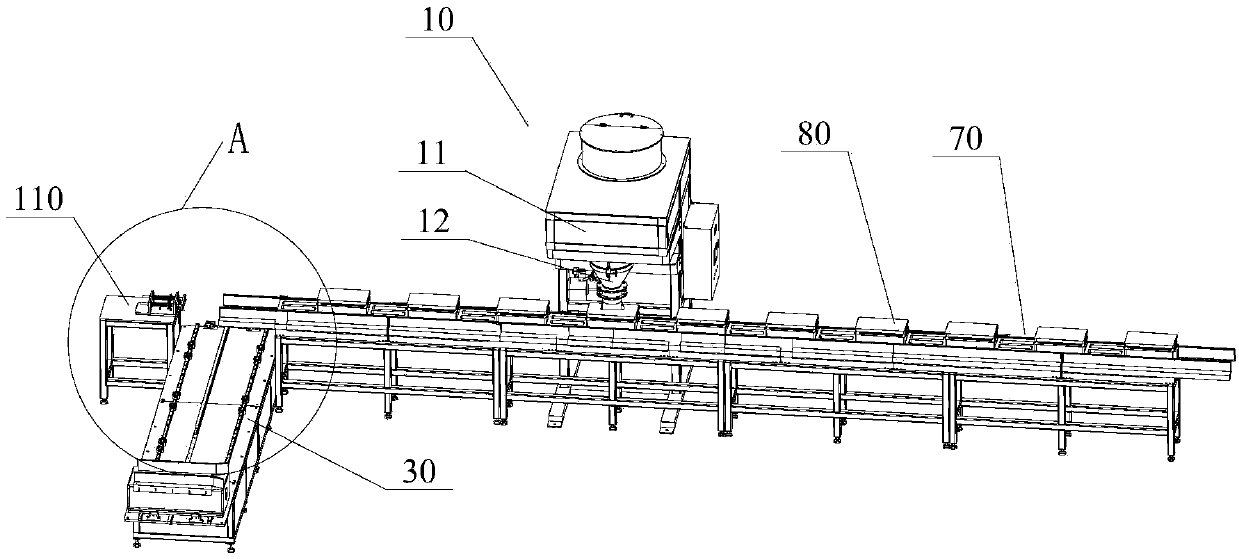

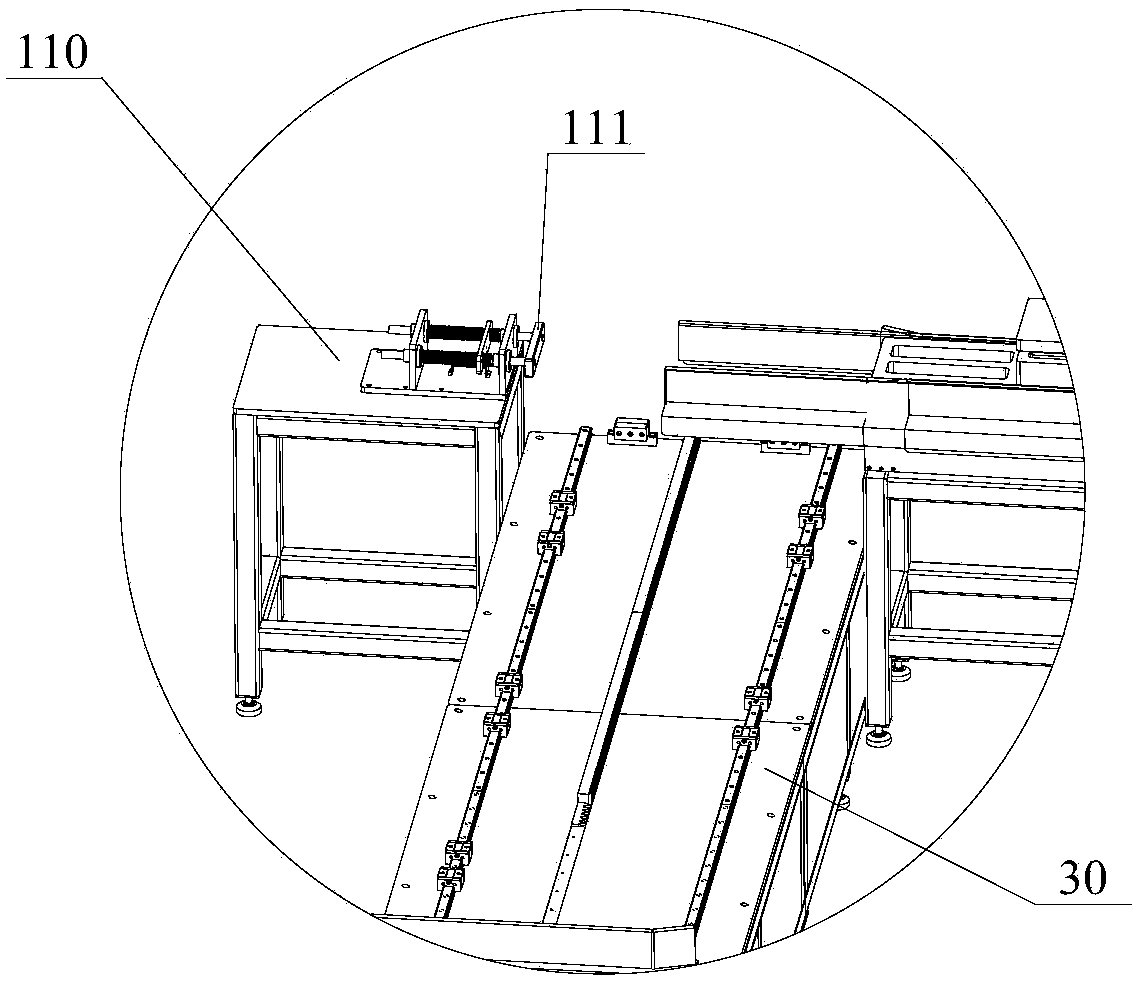

[0039] The present invention provides a fully automatic production line system for gold ingots and silver ingots. The present invention will be described in detail below in conjunction with specific embodiments and accompanying drawings.

[0040] Such as figure 1 As shown, the fully automatic production line system for gold ingots and silver ingots provided by the present invention sequentially includes a weighing and unloading mechanism 10, a material shifting and closing mechanism 20, a first conveying trolley mechanism 30, a melting furnace main body 50, The second conveying trolley mechanism 90 and the uncapping and reclaiming mechanism 60 . The granular raw materials of gold and silver ingots to be processed are weighed and fed into the graphite mold 80, then the upper surface is smoothed and the graphite mold 80 is covered, and then the main body of the melting furnace 50 is heated and melted through transportation, and then transported , and then open the cover to take...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com