Passenger train axle box drying line

A technology for railway passenger cars and drying lines, which is applied in the fields of surface pretreatment, coating, and devices for coating liquids on surfaces, etc., can solve the problems of maintenance intensity and maintenance requirements, affecting workers' health, and difficult to control fire hazards, etc. The effect of reducing equipment failure rate, increasing drying and heating area, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

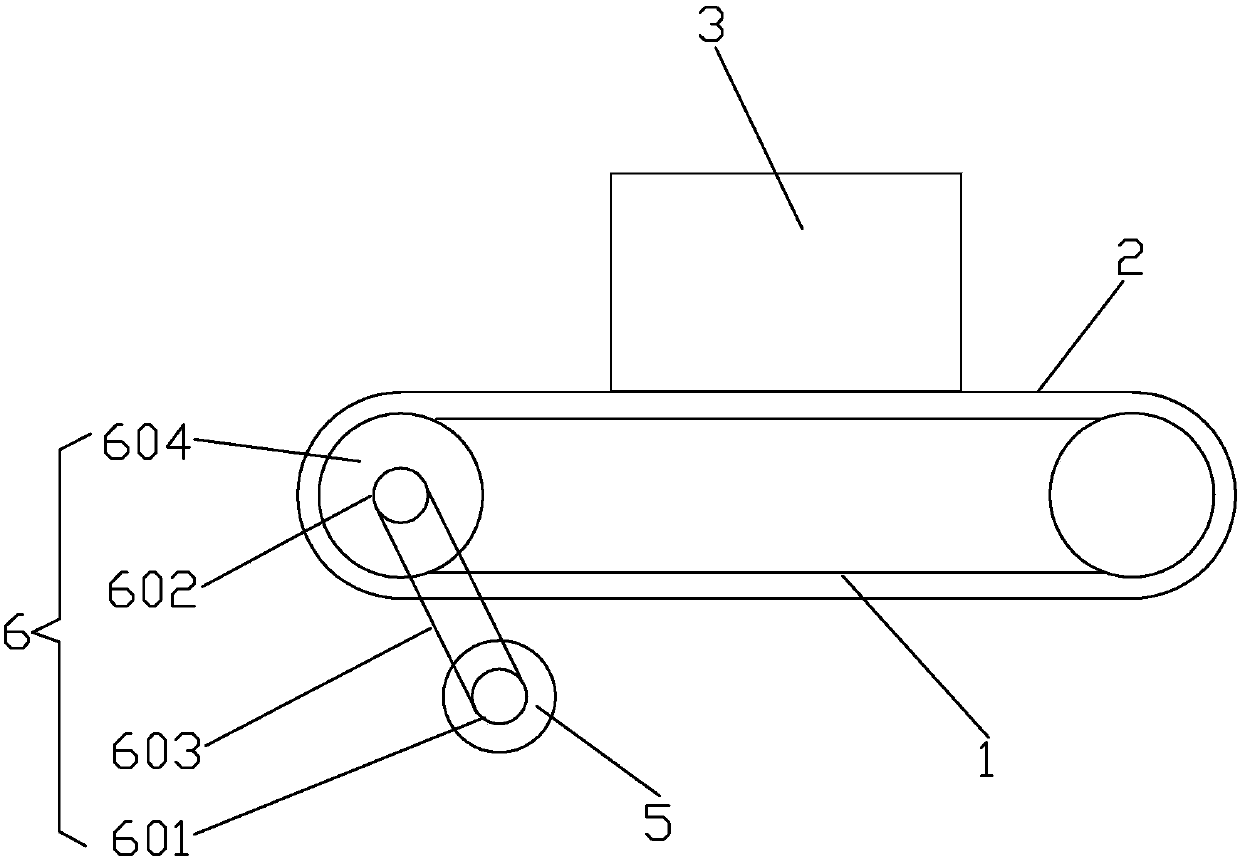

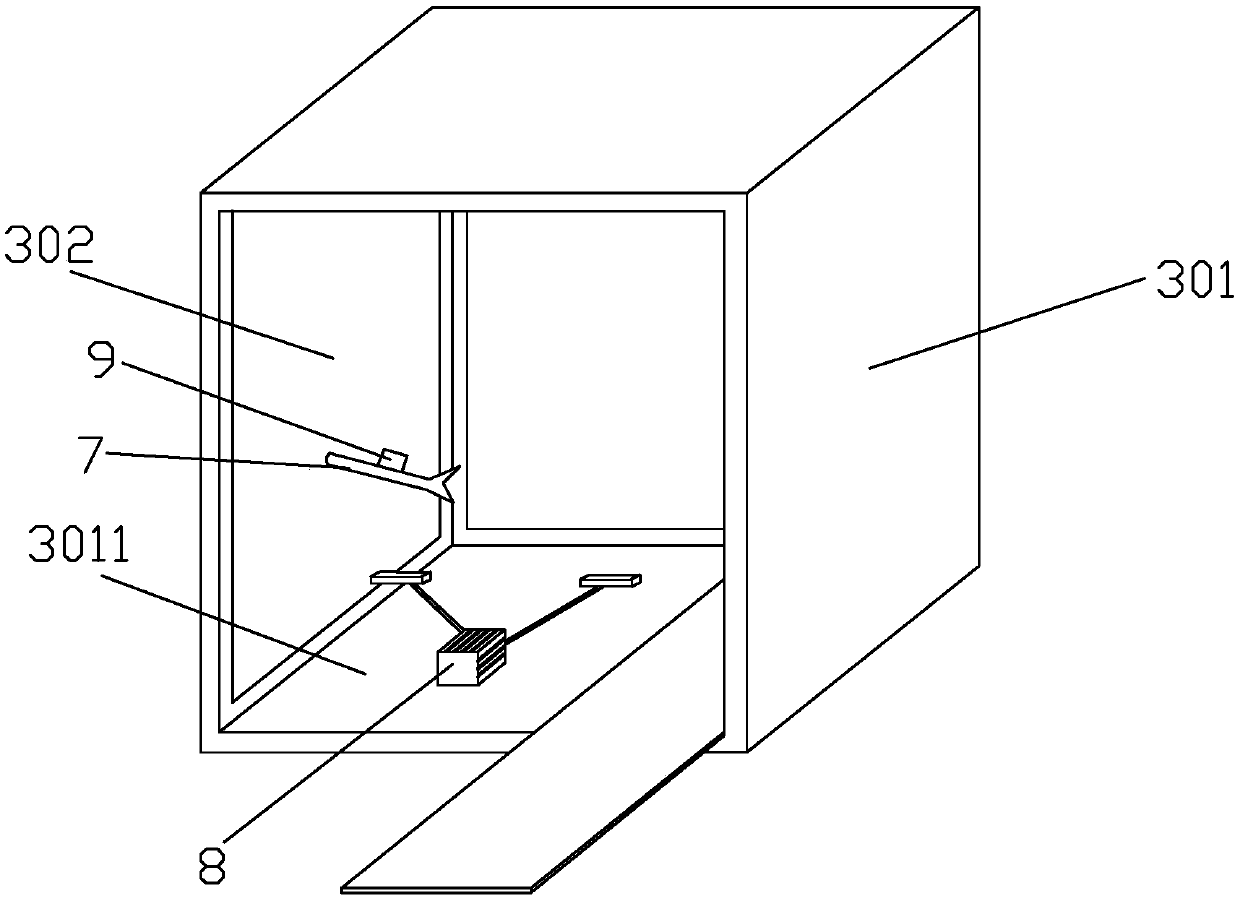

[0024] A railway passenger car axle box drying line provided in this embodiment has a structure such as Figure 1-4 As shown, it includes a frame 1, a conveyor belt 2, a driving device and a drying device 3. The conveyor belt 2 rotates around the frame 1 to form a conveyor line, the driving device drives the conveyor belt 2 to rotate, and the drying device 3 is arranged above the conveyor belt 2 .

[0025] The drive device includes a drive motor 4 , a first drive unit 5 and a second drive unit 6 connected in sequence, the first drive unit 5 is connected to the drive motor 4 , and the second drive unit 6 is connected to the first drive unit 5 and the conveyor belt 2 .

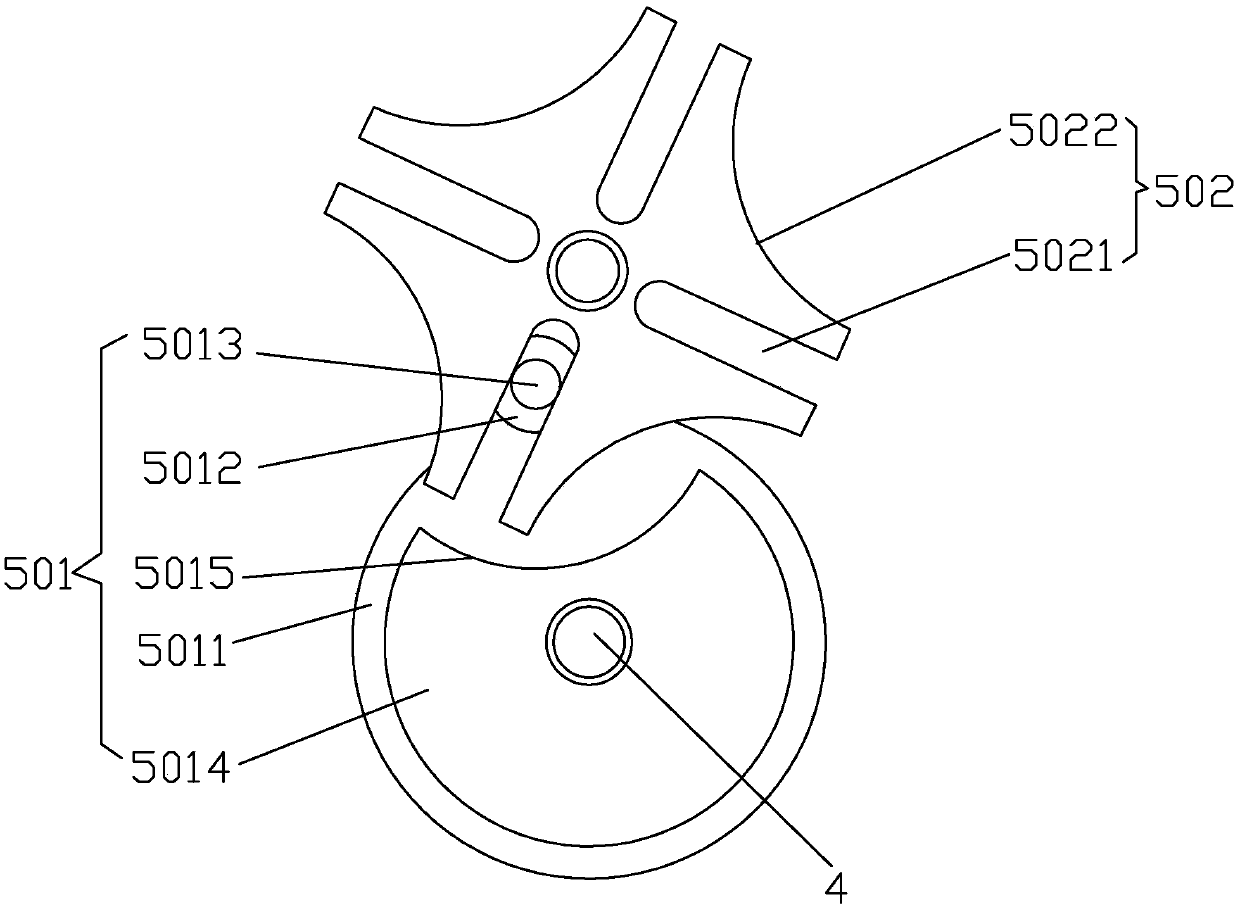

[0026] The first drive unit 5 includes a driving disc 501 and a driven disc 502 . The center of the driving disk 501 is fixed to the output end of the driving motor 4. The driving disk 501 includes a circular turntable 5011, and the edge of the turntable 5011 is provided with a convex circular connection part 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com