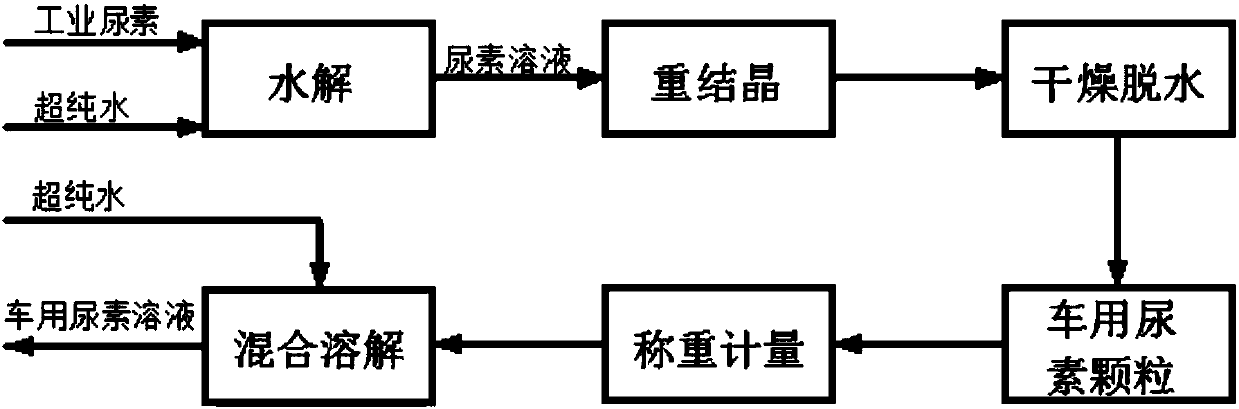

Production process and system for preparation of automobile urea solution from industrial urea

A technology for vehicle urea and production process, applied in the field of chemical process, can solve the problems of reverse osmosis membrane flux and anti-pollution performance limiting production capacity, product quality is difficult to meet requirements, complex filtration and purification processes, etc. The effect of mass production, sufficient and stable market supply, and meeting the needs of small batch orders

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

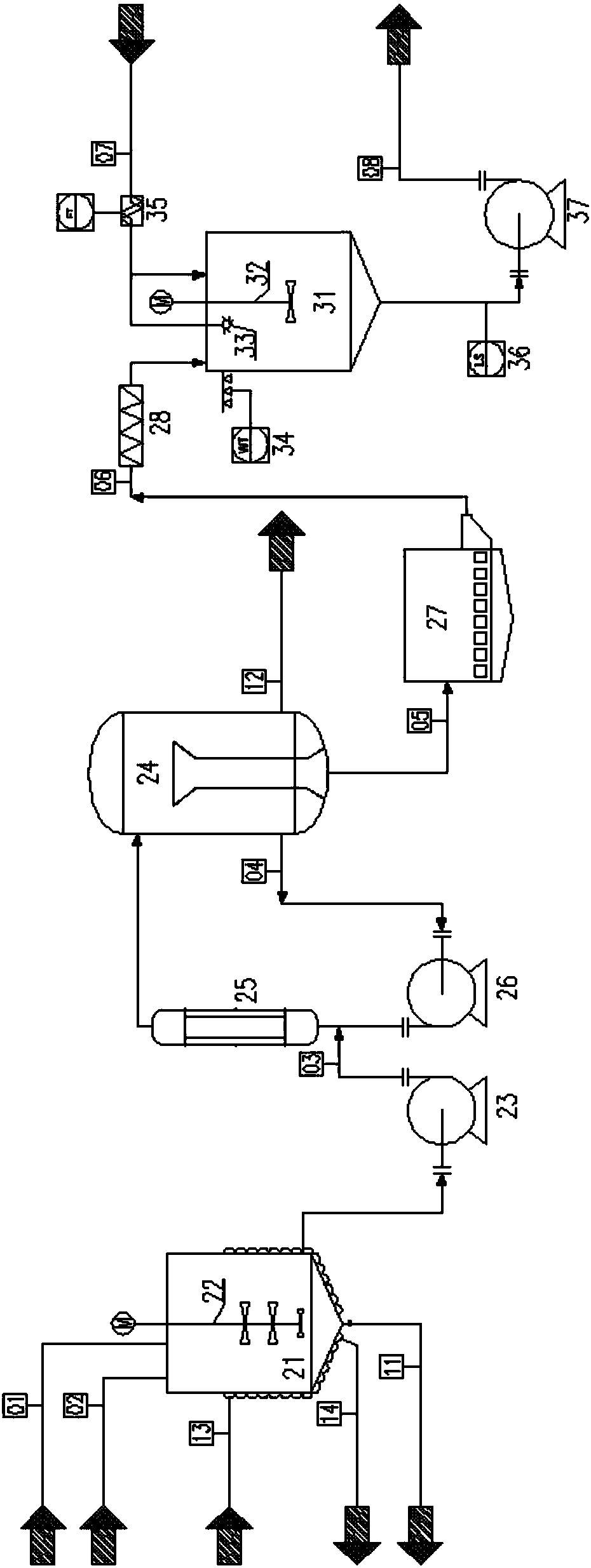

[0074] The production technology raw material of present embodiment is industrial urea qualified product, and wherein biuret content is 1%, and insoluble matter content is 400ppm, and alkalinity (as NH 3 Total) is 300ppm, iron content is 10ppm, and all the other components are urea.

[0075] The raw material is mixed with ultrapure water in the dissolving kettle 21 and dissolved in the water. The operating temperature of the dissolving kettle 21 is 60-80° C. and the operating pressure is normal pressure. Heating steam is fed into the outer coil of the dissolution kettle 21 to provide a heat source for the dissolution process, and the steam condensate is recovered through the pipeline. The dissolving process was about 1.5 hours, and the upper layer urea solution was pumped into the crystallizer 24.

[0076] The industrial urea solution from the dissolution tank 21 is mixed with the circulating liquid of the crystallizer 24 and then enters the tube side of the crystallization c...

Embodiment 2

[0082] For the production process involved in the present invention, the operation process of embodiment 2 is the same as that of embodiment 1. The difference between embodiment 2 and embodiment 1 is: the raw material is industrial urea first grade product, wherein biuret content is 0.9%, insoluble matter content is 100ppm, alkalinity (in NH 3 Total) is 200ppm, iron content is 5ppm, and all the other components are urea.

[0083] In the final vehicle urea solution, the urea content is 32.5% (mass fraction), and the water content is 67.5% (mass fraction), wherein the biuret content is no more than 0.3% (mass fraction), and the insoluble matter content is no more than 10ppm. (in NH 3 Total) does not exceed 15ppm, iron content does not exceed 0.3ppm, and all indicators meet the requirements of the Beijing local standard DB11 / 552-2008 "Urea Solution for Vehicles".

[0084] The NOx conversion rate of the prepared vehicle urea solution is 97%, and the NOx emission meets the requir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com