Multi-layer independent rotating platform

A technology of independent rotation and platform, applied in the direction of display table, display hanger, display shelf, etc., to achieve the effect of simple assembly and disassembly, saving development time, and solving the effect of winding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

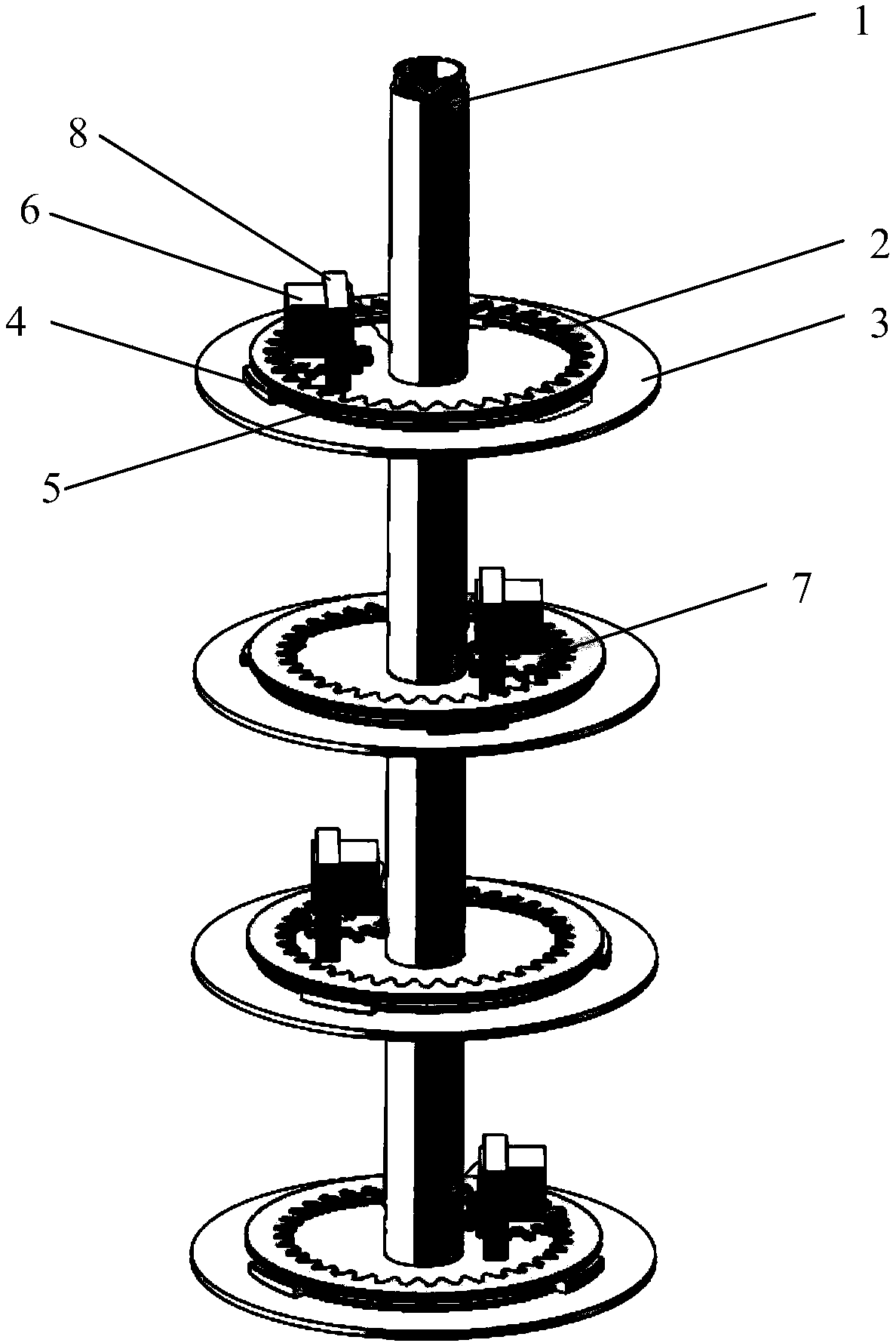

[0019] The structure of the multi-layer independent rotating platform of the present invention is described in conjunction with the accompanying drawings.

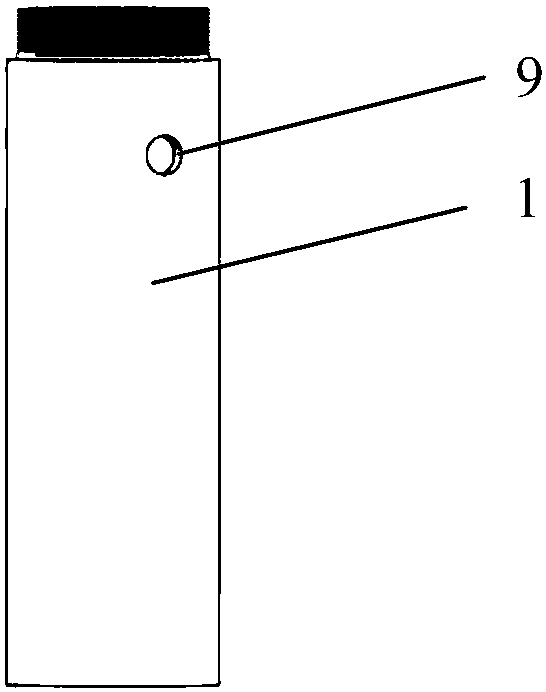

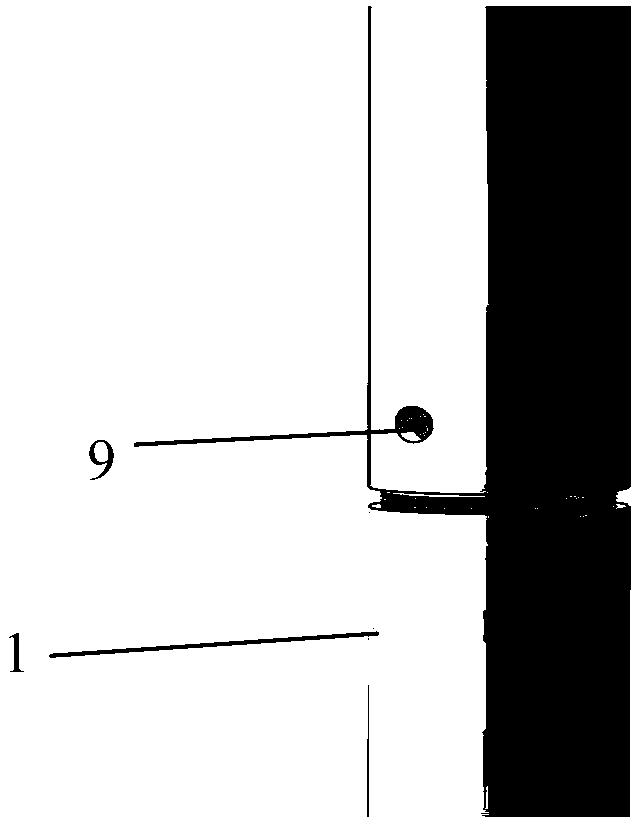

[0020] Such as figure 2 As shown, the central column 1 is tubular, one end of the central column 1 has an internal thread, and the other end has an external thread, and the outer diameter of one end of the external thread of the central column 1 is smaller than the outer diameter of the central column 1, and the central column 1 can be connected end to end through threads; The platform 3 is in the shape of a disk, and there are circular holes evenly distributed on the periphery of the platform 3, and the center is a circular hole, such as image 3 As shown, the aperture is larger than the outer diameter of the external thread of the central column 1, and smaller than the outer diameter of the central column 1. The platform 3 passes through one end of the external thread of the central column 1 and is sandwiched between th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com