Foaming agent for cakes and preparation method thereof

A cake foaming agent and emulsifier technology, applied in baking, dough processing, food science, etc., can solve the problems of delay in production time, slow flow speed, low fluidity, etc., to improve inelasticity, simple steps, good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] The preparation method of above-mentioned cake foaming agent, comprises,

[0044] Stirring step: put propylene glycol, emulsifier, preservative and sweetener into the mixer according to the ratio, and stir fully to make the primary mixture;

[0045] Aqueous phase preparation steps: mixing pure water and sorbitol, stirring evenly, heating and keeping warm, to obtain a prefabricated mixture;

[0046] One mixing step: add the primary mixture to the prefabricated mixture and stir evenly to obtain the water phase mixture;

[0047] Emulsification step: pump the water phase mixture into the emulsification pot and heat it;

[0048] Oil phase preparation steps: heating sorbitan monostearate and keeping it warm;

[0049] Secondary mixing step: add the heated sorbitan monostearate into the emulsification pot, mix with the water phase mixture, homogenize and keep warm;

[0050] Cooling and boxing step: put the emulsification pot at room temperature and let it stand, after coolin...

Embodiment 1-10

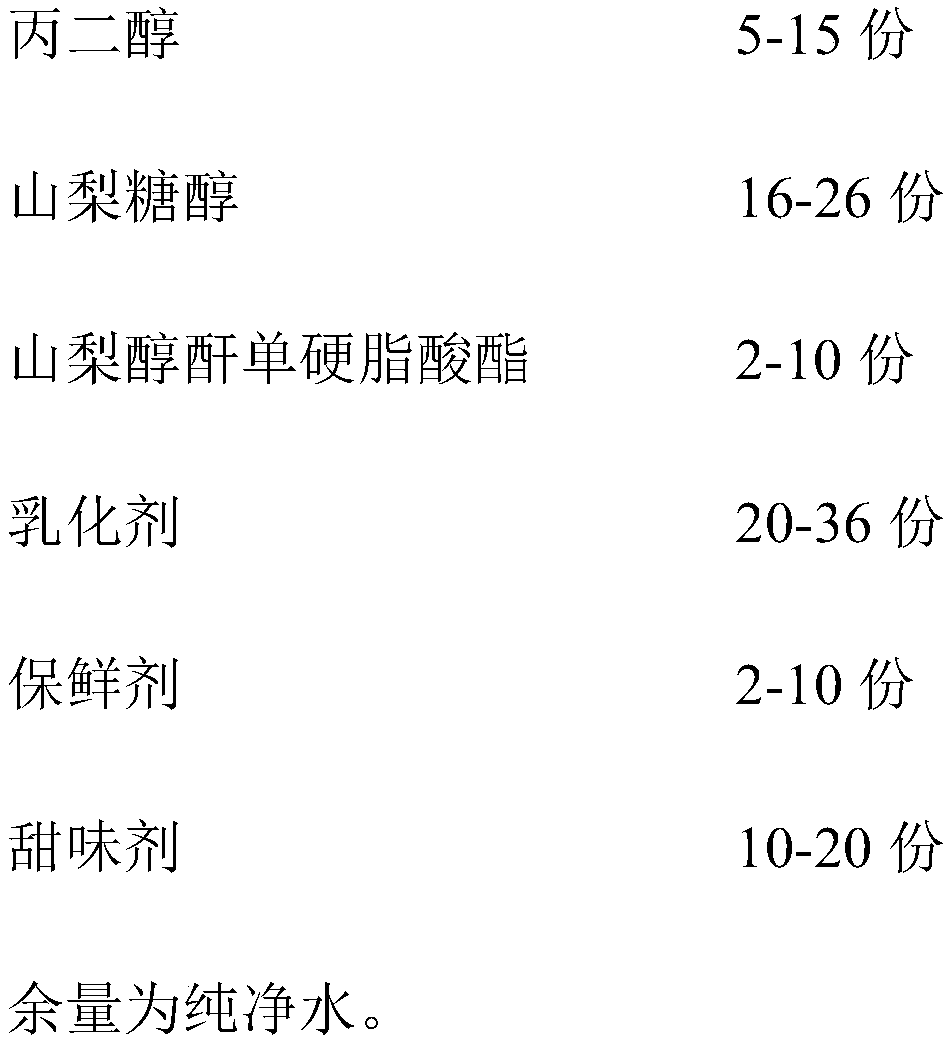

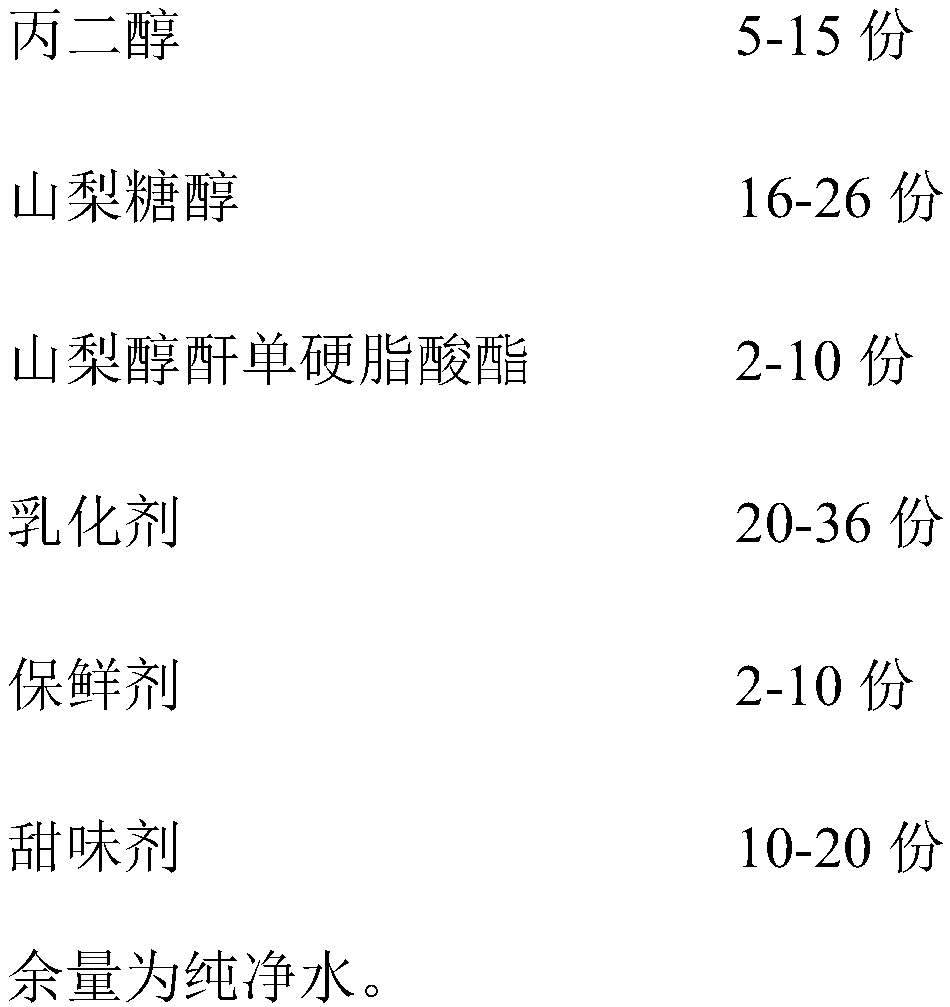

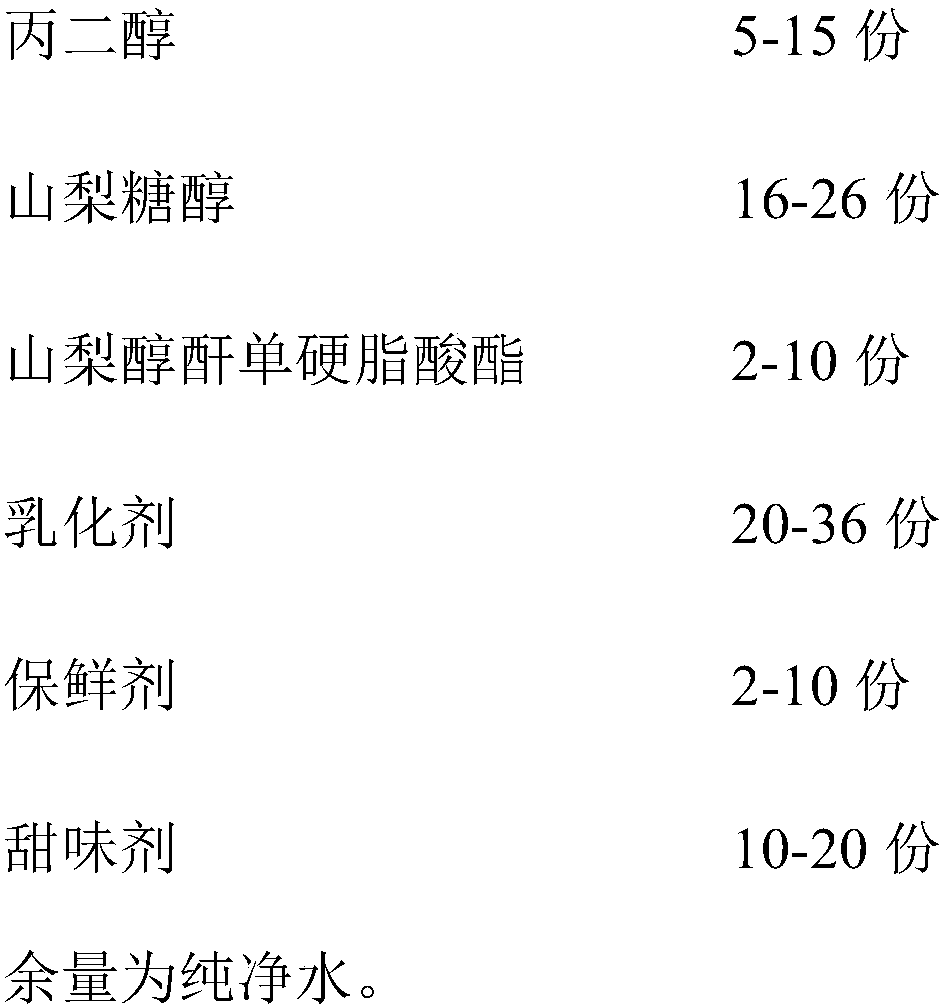

[0057] The parts by weight of the components of Examples 1-10 are shown in the table below.

[0058] Table 1 Embodiment 1-10 proportioning

[0059]

[0060] Wherein, the emulsifying agent of embodiment 1 is 24 parts of single, diglyceride fatty acid ester, 12 parts of sucrose fatty acid ester; Antistaling agent is monocapric glyceride; Sweetener is 10 parts of cyclamate, 10 parts of neotame.

[0061] The emulsifiers of Examples 2, 4, and 5 are mono- and diglyceride fatty acid esters; the antistaling agent is 2 parts of monocapric glycerides and 4 parts of mono-monoglycerides; the sweetener is saccharin.

[0062] The emulsifier in Example 3 is sucrose fatty acid ester; the antistaling agent is 1 part of monoglyceride and 1 part of sucrose glyceride; the sweetener is 2 parts of neotame, 4 parts of acesulfame potassium and 4 parts of sucralose.

[0063] Embodiment 6-10 is consistent with the component composition of embodiment 1 same content.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com