Metastable austenitic stainless steel band or sheet and manufacturing method therefor

A technology of austenitic stainless steel, manufacturing method, applied in the direction of manufacturing tools, furnace types, furnaces, etc., which can solve the problems of reduced ductility of parts, deformation size of formed parts, and reduced toughness of parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0097] Hereinafter, examples will be described together with comparative examples.

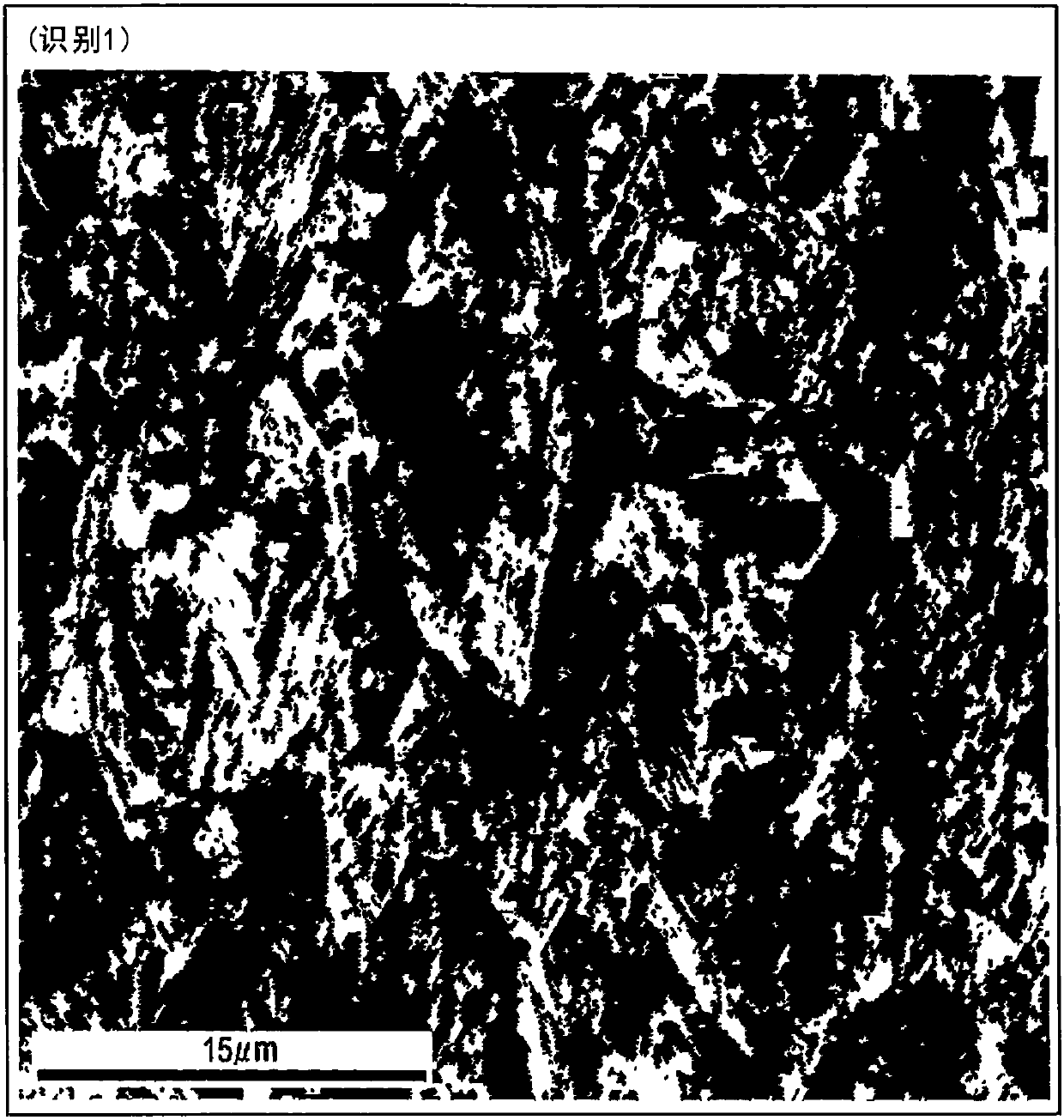

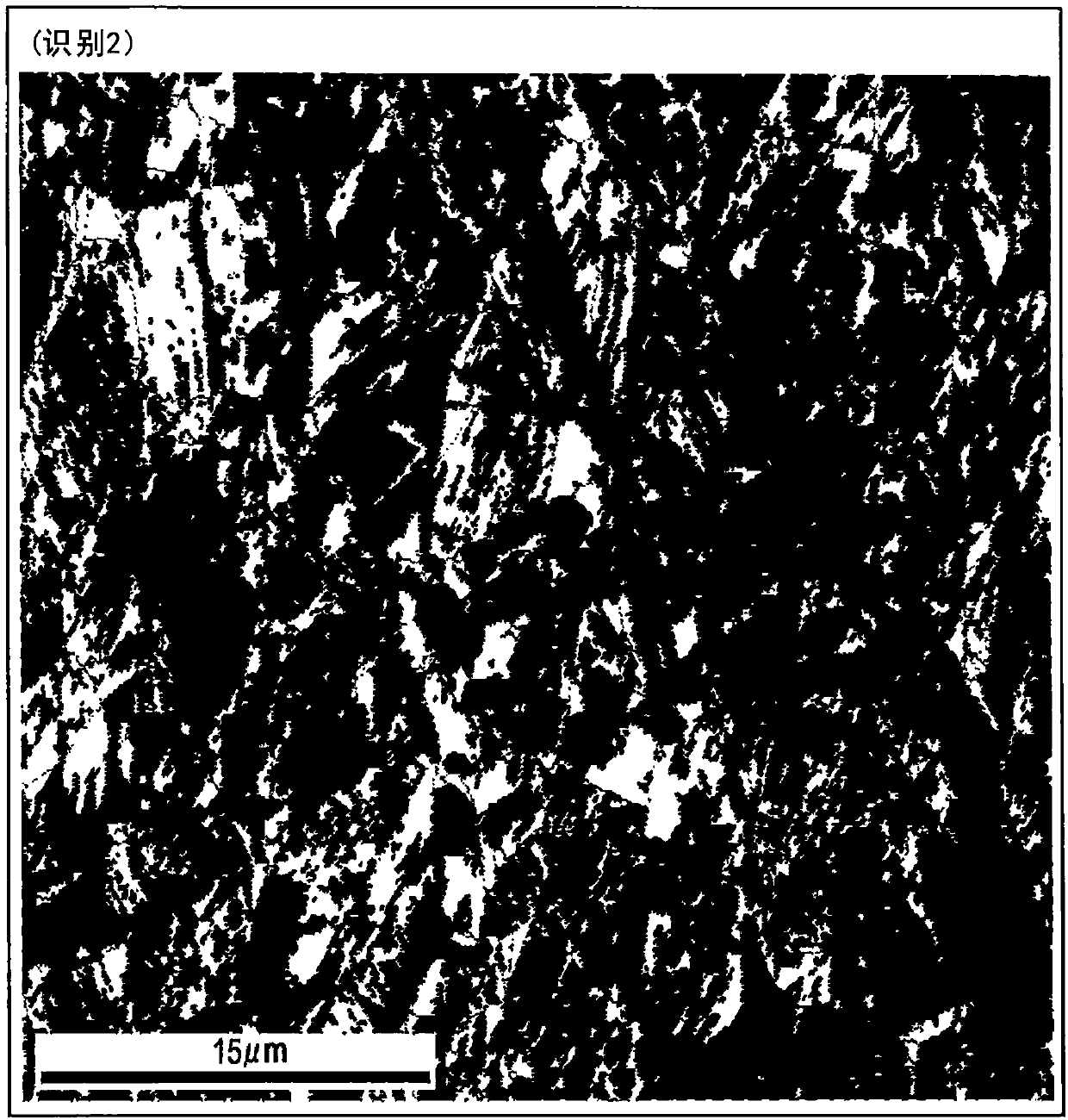

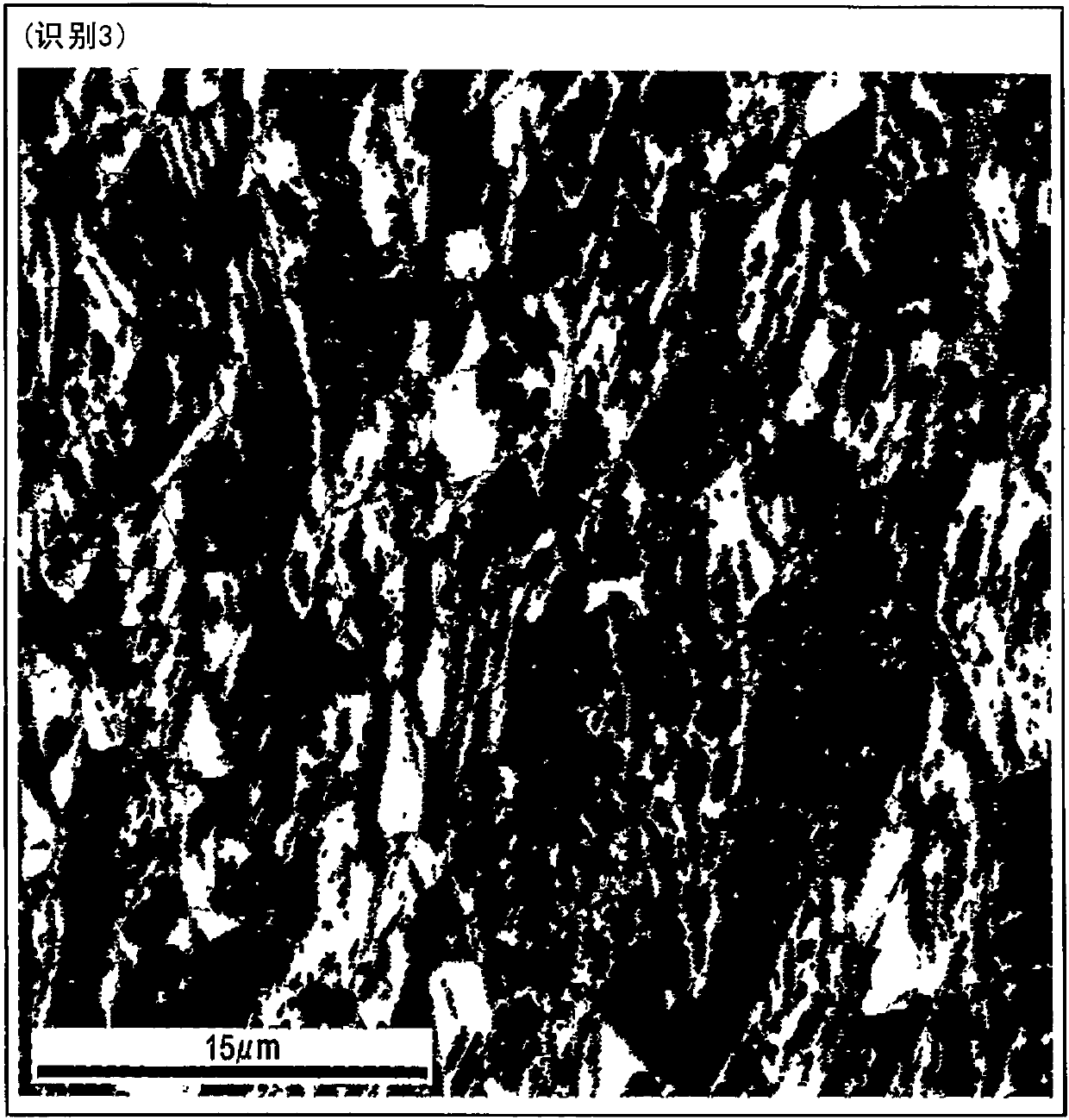

[0098] Example steel grade 1 and comparative example steel grades 2 to 4 having different Mo contents were prepared. Table 1 shows its chemical composition. Next, in Example steel type 1 in Table 1, steels having a metal structure within the range of the present invention (identification 1 to 5 samples) and steels having a metal structure outside the range of the present invention (identification 6 , 7 samples). Table 2 shows the metallographic structures of these steels. In addition, Table 3 shows the production conditions of these steels. The hardness (HV), tensile strength (Ts), 0.2% proof strength (YS), and elongation (EL) of the produced steel (samples identified 1 to 7) were measured and shown in Table 4, respectively. In addition, in Tables 1-4, the numerical value with "*" attached to the left side shows the value outside the range of this invention.

[0099] Table 1 (composition)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com